Aircraft engine grate seal sealing structure

A technology of aero-engine and sealing structure, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., and can solve problems such as difficult to achieve circumferential blockage and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

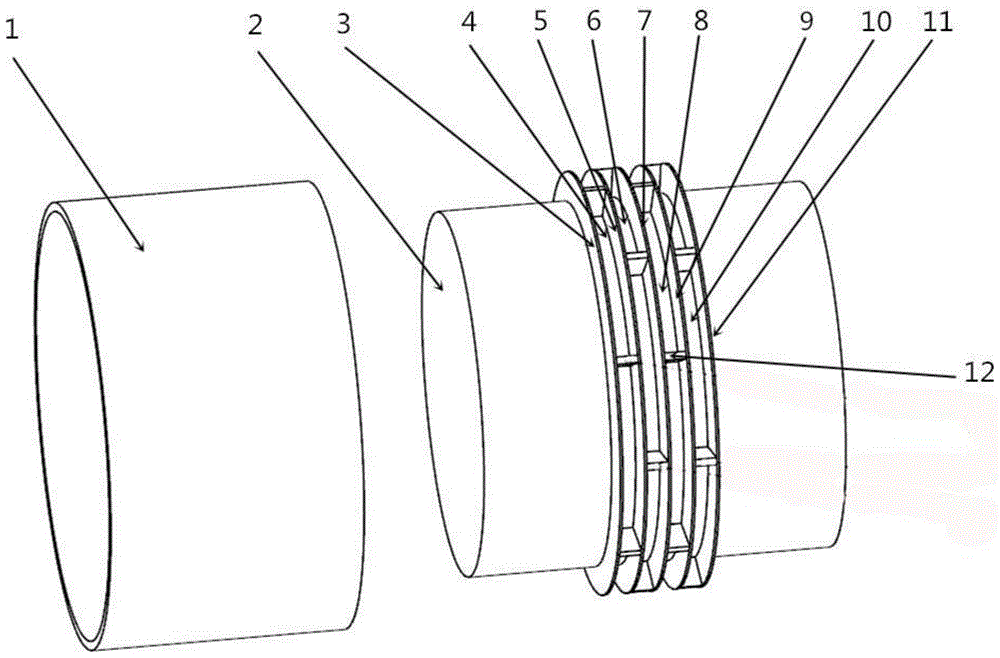

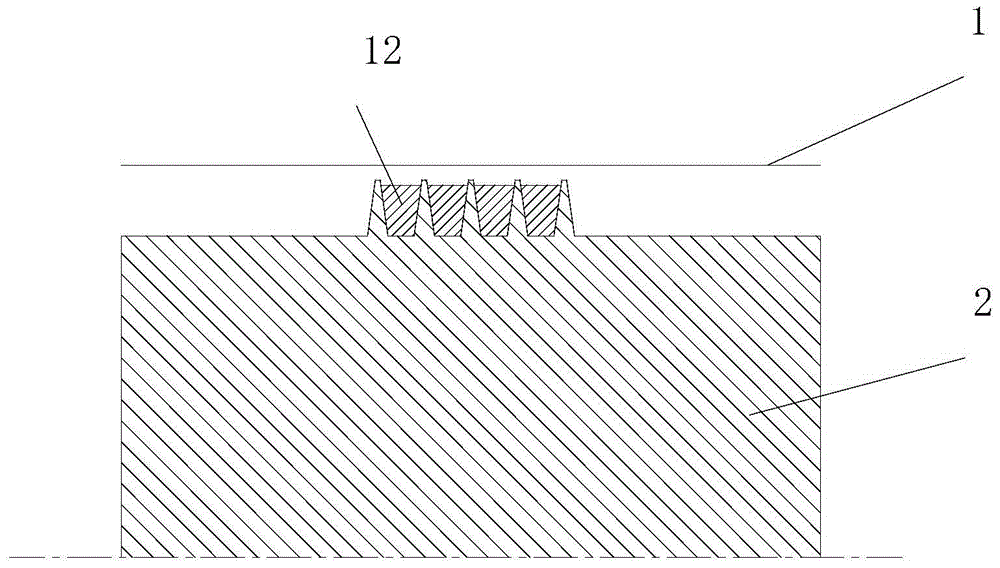

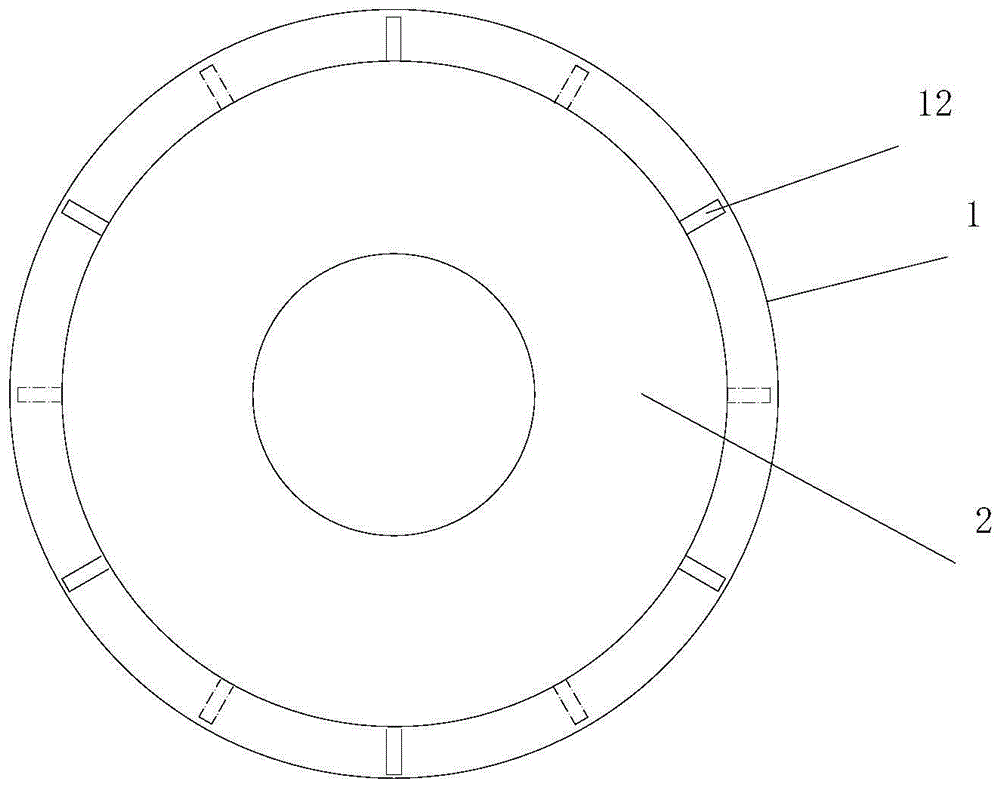

[0019] The aero-engine grate sealing structure as shown in the figure includes a sealing bush 1 and a rotating shaft 2. There are 5 stages of grating teeth on the rotating shaft 2, the first-stage grate teeth are 3, the second-stage grate teeth are 5, and the third-stage grate teeth 7. Four-stage grate teeth 9, five-stage grate teeth 11; grate tooth chambers are formed between two adjacent grate teeth, the first grate tooth chamber 4, the second grate tooth chamber 6, the third grate tooth chamber 8, The fourth grate tooth cavity 10; the circumferential tooth cavity partitions 12 are arranged in the grate tooth cavity, distributed in a circular array with an interval of 60°, and the tooth cavity partitions 12 in two adjacent grate tooth cavities are distributed at an interval of 30°.

[0020] The tooth chamber partition 12 is parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com