An easy-to-replace straw briquette forming mechanism

A molding mechanism and straw technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of fast wear of the outer teeth of the pressure wheel and the inner teeth of the ring die, short service life, unfavorable material extrusion molding, etc., to achieve long service life, Less wear, reduced circumferential flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

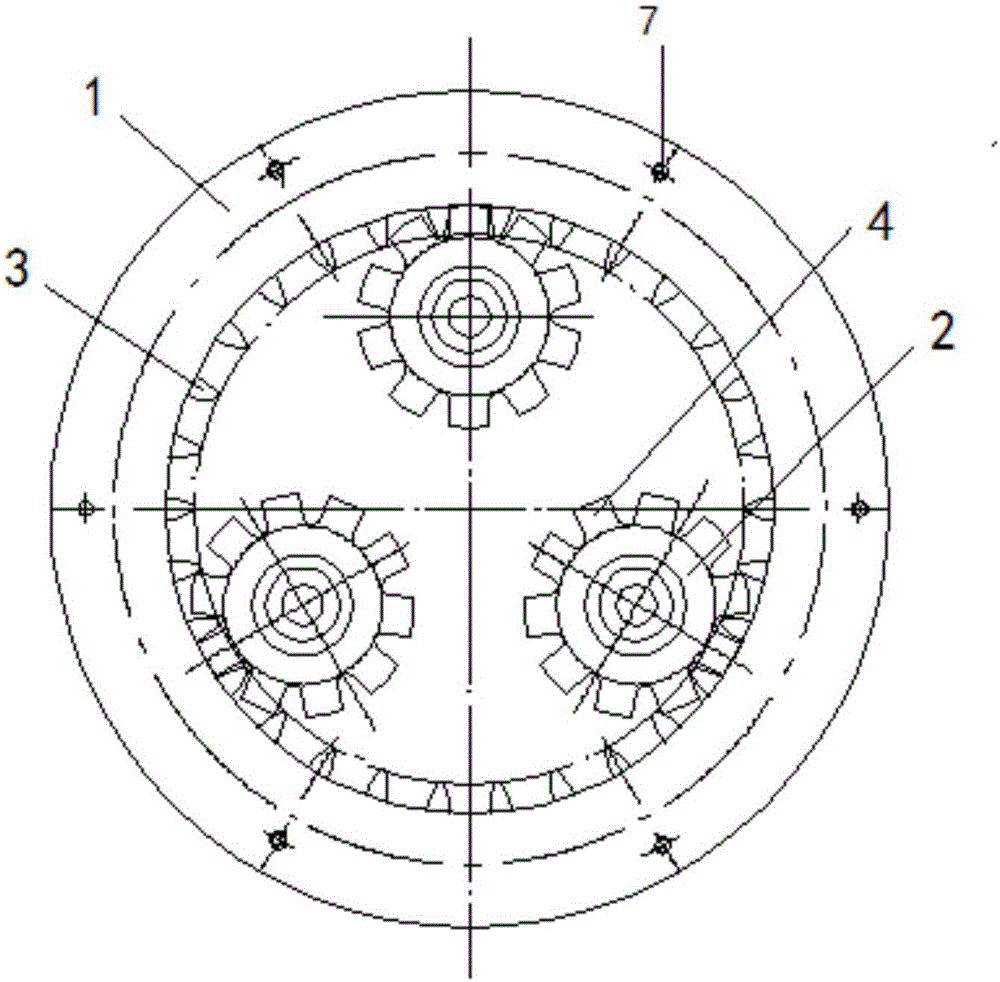

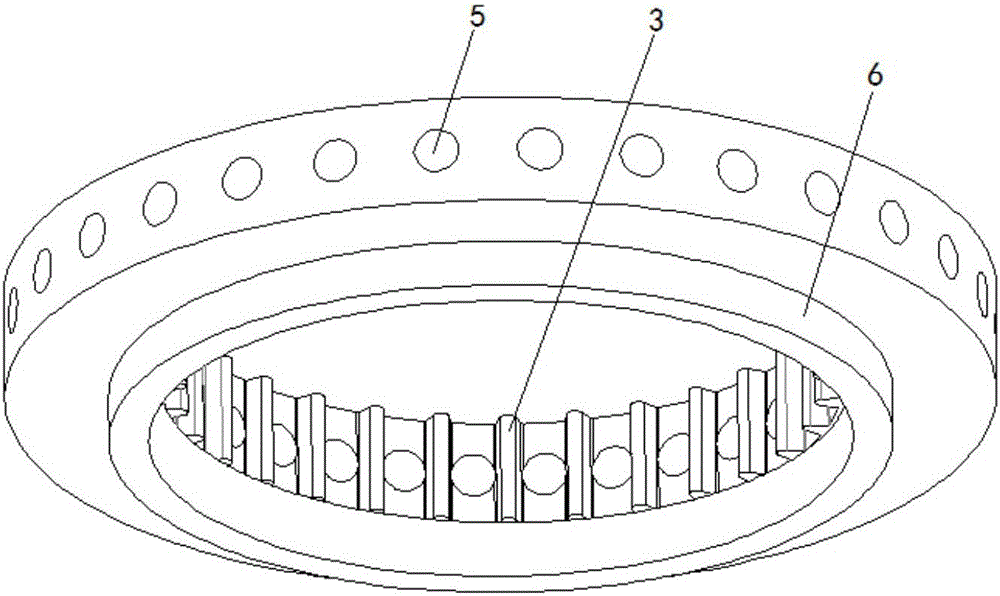

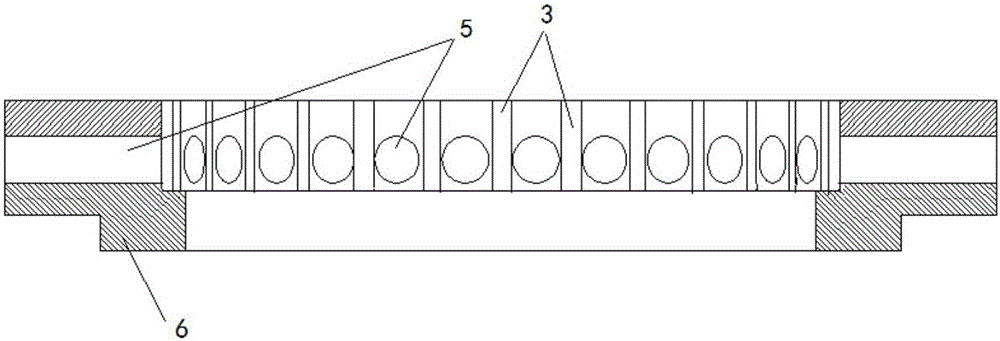

[0026] Attached below figure 1 , 2 , 3 Describe the first embodiment of the present invention.

[0027] An easy-to-replace straw briquette forming mechanism, comprising a ring die 1 and three planetary pressure wheels 2 arranged uniformly in the ring die 1, internal teeth 3 are evenly distributed on the inner diameter of the ring die 1, and the planetary pressure wheels Outer teeth 4 are evenly distributed on the outer diameter of 2, and the inner teeth 3 and outer teeth 4 are in a non-engaging state; the ring die 1 is fixed, and the planetary pressure wheel 2 rotates around the ring die while being driven by the planetary transmission mechanism. 1 revolution; radial extrusion holes 5 are formed between the adjacent inner teeth 3 . The cross-section of the radial extrusion hole 5 is circular with a diameter of 30-40mm.

[0028] The gear ratio between the ring die 1 and the planetary pressure wheel 2 is equal to the transmission ratio of the planetary transmission mechanism....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com