Composite floorboard

A composite flooring and wooden flooring technology, applied in the field of composite flooring, can solve problems such as easy deformation of wooden floor joints, living environment pollution, difficulties, etc., and achieve good sound insulation effect, tight fit, and improved strain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

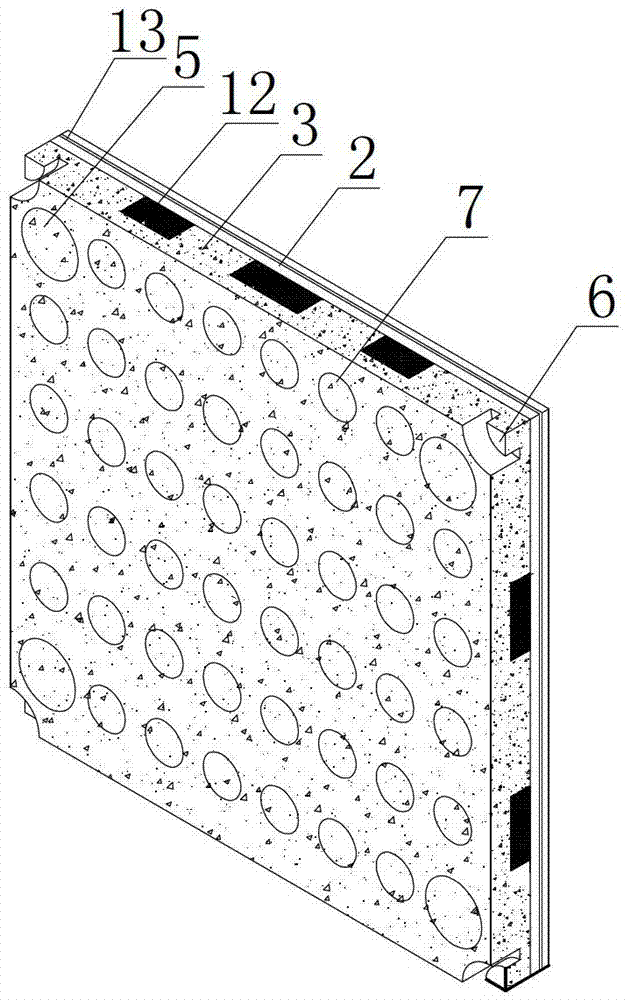

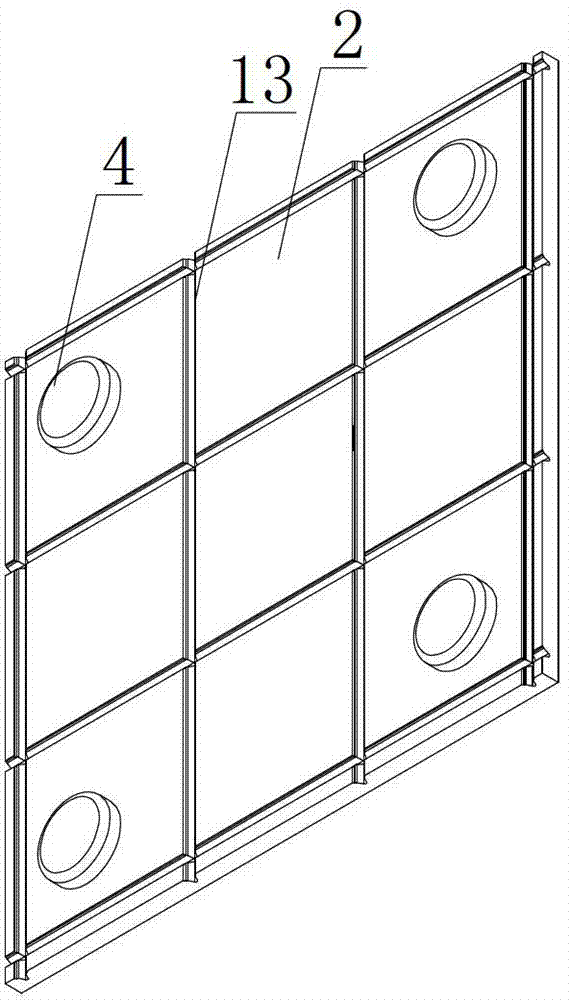

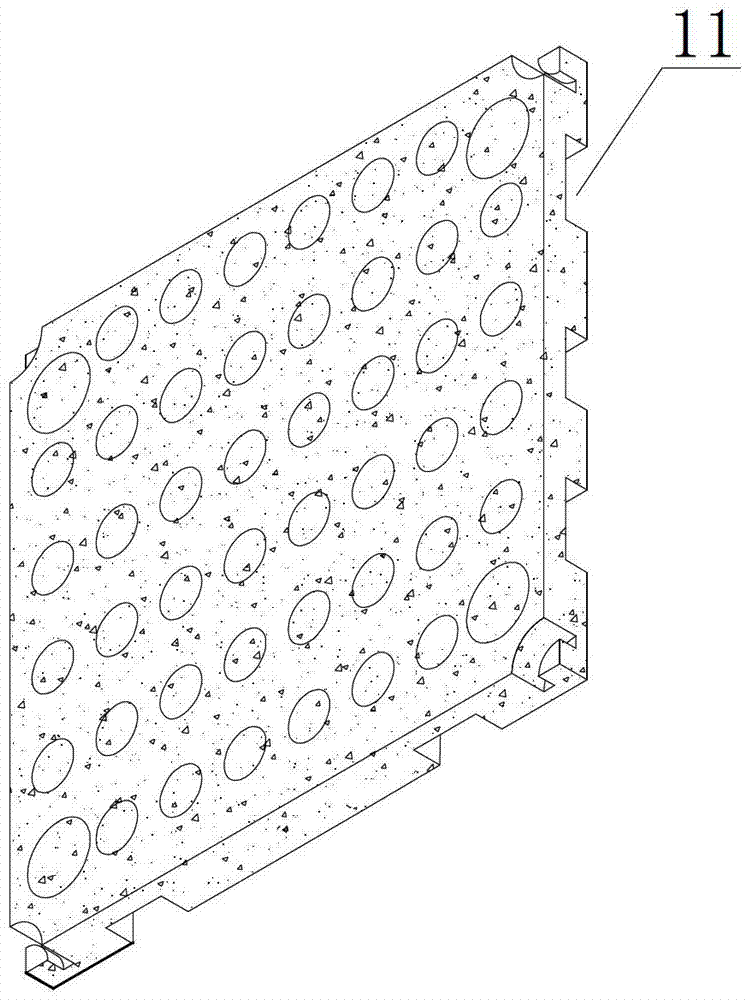

[0023] Specific embodiment 2 of the present invention: as Figure 1 to Figure 5 In the composite floor shown, the composite floor body 1 is provided with a wooden floor body 2 and a second layer board 3 sequentially from top to bottom, and the lower surface of the wooden floor body 2 is provided with positioning bosses 4 and evenly distributed stress relief Groove 13, the upper surface of wooden floor body 2 is provided with nano wear-resistant paint layer 14; The positioning hole 5 that is provided with on the second layer board 3, is provided with positioning block 6 on the four corners of the second layer board 3, the second layer board The side of 3 is provided with storage tank 11, and storage tank 11 is provided with activated carbon compression block 12. The storage grooves 11 on the opposite sides of the second laminate 3 are arranged in a staggered manner, and the depth of the storage grooves 11 is 3 cm. The wooden floor body 2 is made of composite wood material, and...

Embodiment 3

[0024] Specific embodiment 3 of the present invention: as Figure 1 to Figure 5 In the composite floor shown, the composite floor body 1 is provided with a wooden floor body 2 and a second layer board 3 sequentially from top to bottom, and the lower surface of the wooden floor body 2 is provided with positioning bosses 4 and evenly distributed stress relief Groove 13, the upper surface of wooden floor body 2 is provided with nano wear-resistant paint layer 14; The positioning hole 5 that is provided with on the second layer board 3, is provided with positioning block 6 on the four corners of the second layer board 3, the second layer board The side of 3 is provided with storage tank 11, and storage tank 11 is provided with activated carbon compression block 12. The storage grooves 11 on the opposite sides of the second laminate 3 are arranged in a staggered manner, and the depth of the storage grooves 11 is 5 cm. The wooden floor body 2 is made of bamboo and wood, and the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com