In-water drilled pile foundation construction system capable of recovering steel protective barrels and construction method thereof

A technology for foundation construction and steel casing, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problem that the steel casing cannot be recycled, and achieve the effect of realizing reuse, solving the problem of non-recycling and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

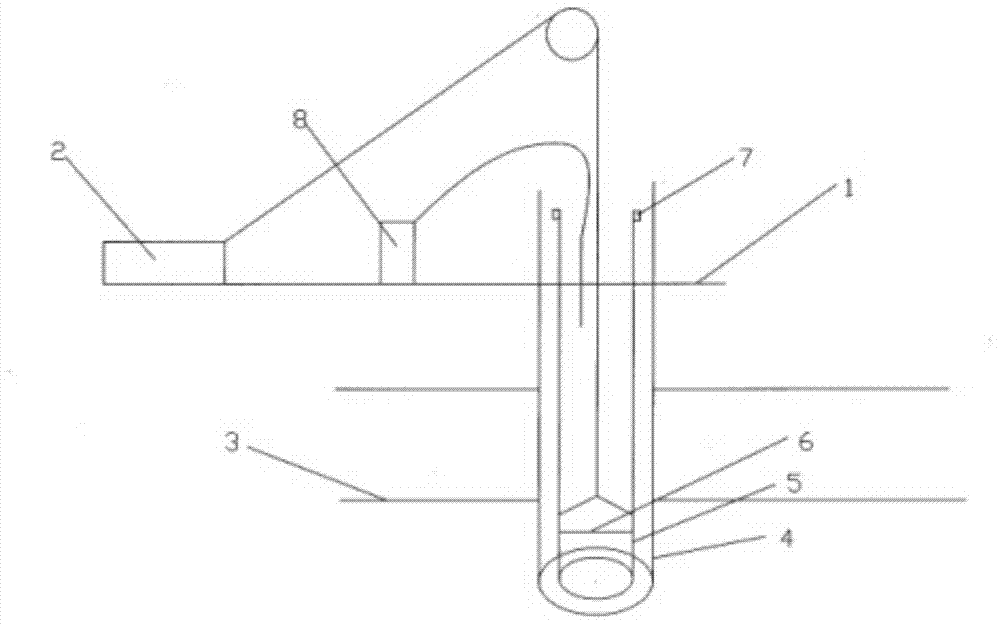

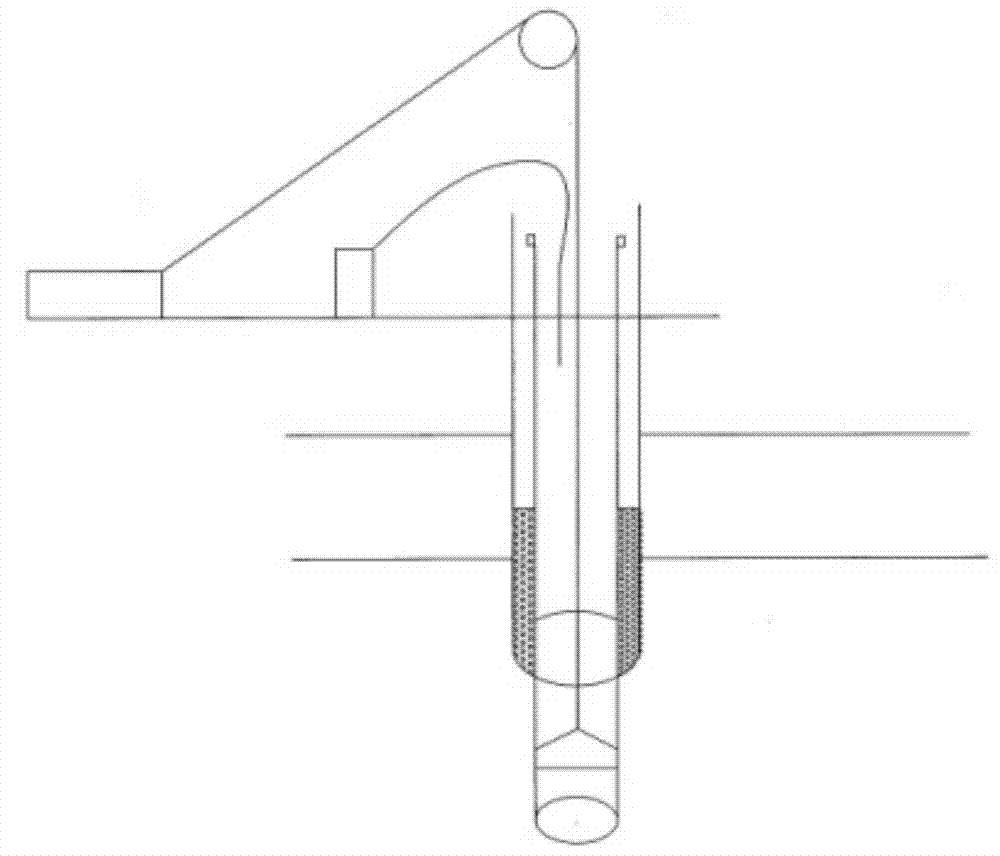

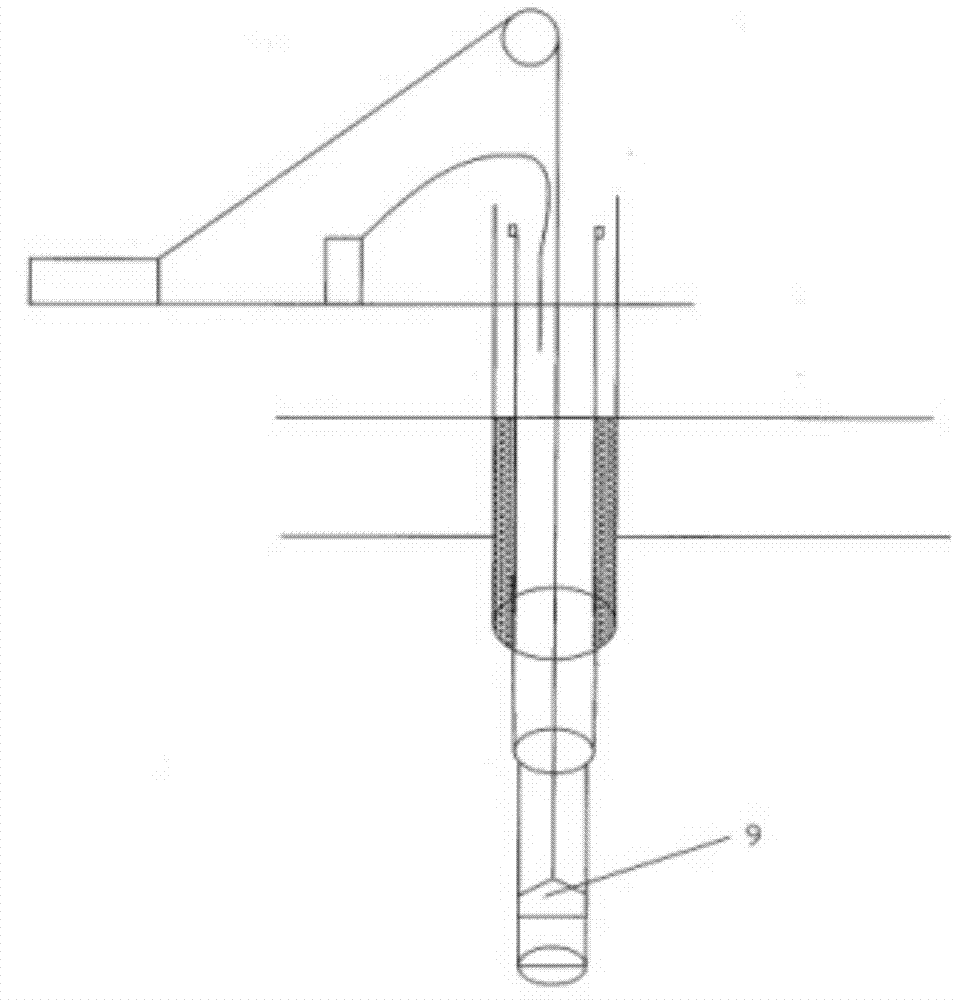

[0033] Such as Figure 1-3 As shown, the underwater bored pile foundation construction system of the recyclable steel casing of this embodiment includes: an offshore drilling platform 1 located on the sea surface, and a crawler crane (not shown in the figure) located on the offshore drilling platform 1 And vibratory hammer 2, the outer steel casing 4 arranged between the seabed stable geological layer 3 and the offshore drilling platform 1, the inner steel casing 5 arranged in the outer steel casing 4, the inner steel casing 5 arranged in the inner steel casing 5 The drill bit and the mud pump 8 installed on the offshore drilling platform; a reaction frame and a jack 7 are provided between the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com