An Intelligent Control System of Hydraulic Cone Crusher

An intelligent control system and cone crusher technology, applied in the field of mining machinery, can solve problems such as the inability to adjust the working efficiency in real time, the inability to monitor the operating status of the main engine, and the inability to reach the maximum potential, so as to achieve good product shape, improve product distribution, prevent The effect of overload damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with embodiment.

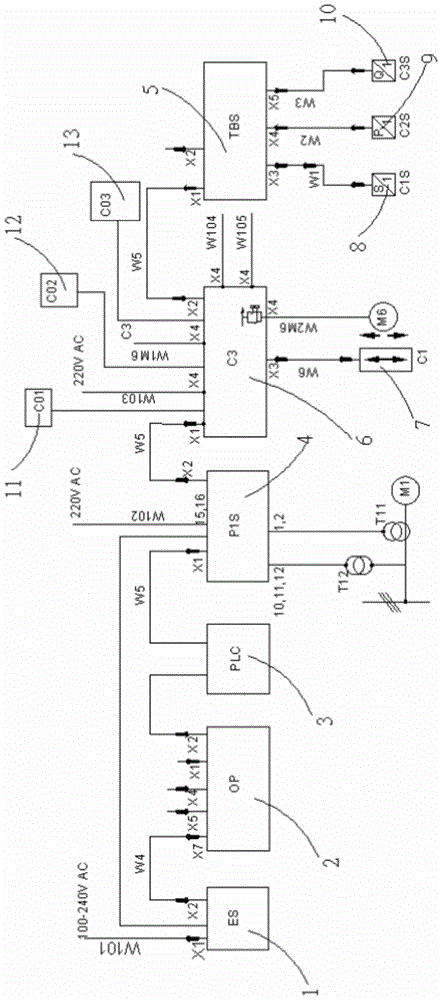

[0043] Such as figure 1 As shown, this embodiment discloses an intelligent control system for a hydraulic cone crusher, including a crusher host, a feeding device, a lubrication system, a hydraulic system, and a CIS connected to the crusher host, a feeding device, a lubrication system, and a hydraulic system The automatic control system is characterized in that: the CIS automatic control system includes a power supply unit 1 connected to each other by a CIS bus or an Ethernet bus, a man-machine interface 2 with a color touch screen, a control unit 3, a power measurement unit 4, and a fuel tank measurement unit. Unit 5, a hydraulic transmission unit 6 connected to the hydraulic system, a manual control switch 7, the power supply unit 1 supplies power to the man-machine interface 2 and the power measurement unit 4; the fuel tank measurement unit 5 is connected to a position sensor 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com