Endoscope and method for manufacturing same

A manufacturing method and technology of endoscopes, applied in the fields of endoscopes, medical science, surgery, etc., can solve problems such as the inability to use endoscope shooting equipment, and achieve the effect of reducing the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

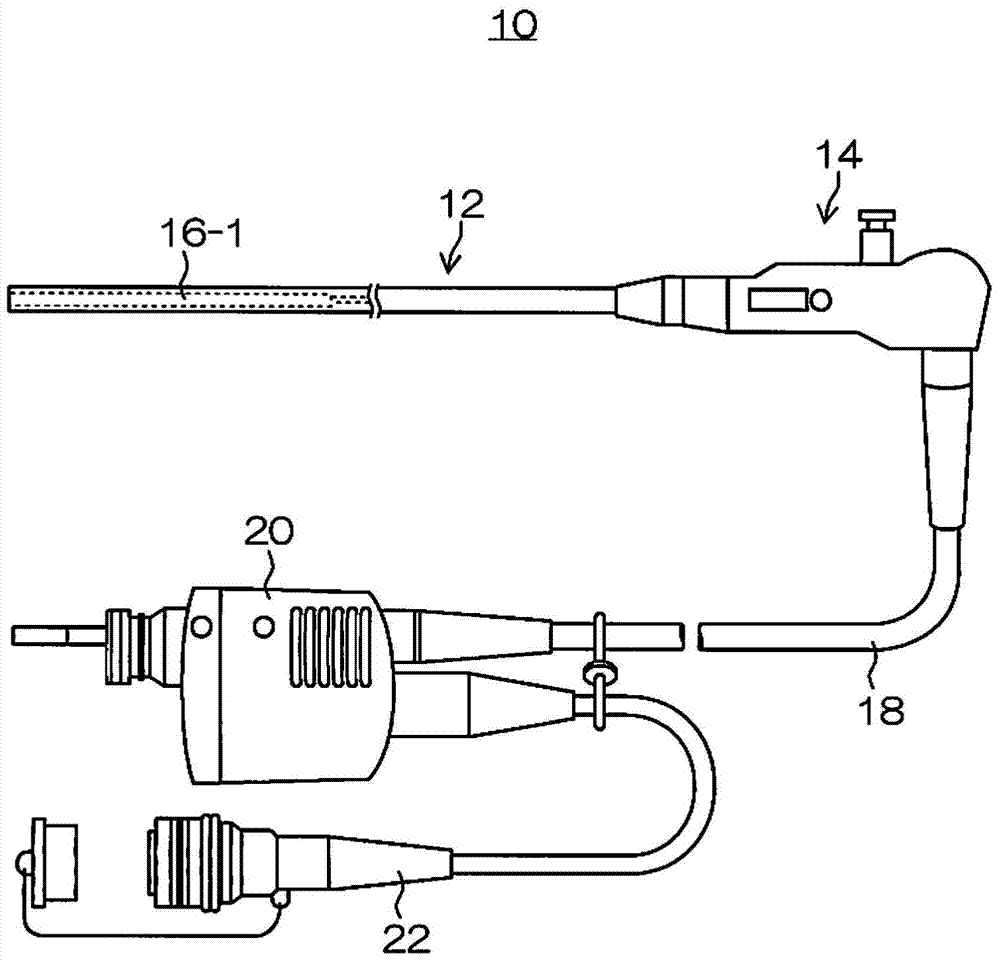

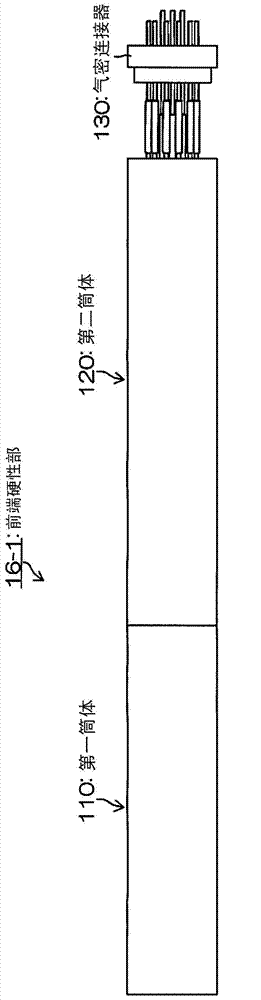

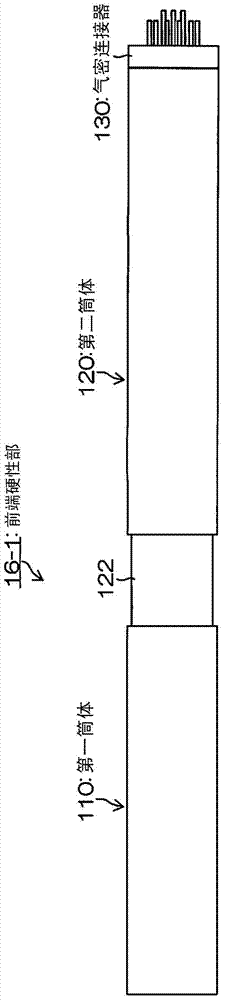

[0048] figure 1 It is an overall configuration diagram showing the first embodiment of the endoscope according to the present invention.

[0049] figure 1 The illustrated endoscope 10 is an electronic endoscope used in surgery, and has an insertion portion 12 inserted into a patient's body cavity, and an operation portion 14 grasped by an operator. The insertion part 12 is provided with the front-end|tip rigid part 16-1 which accommodates the optical unit, the imaging device unit, etc. which are mentioned later. The front end rigid portion 16 - 1 is arranged inside the outer casing of the insertion portion 12 .

[0050] The universal cable 18 is connected to the operation unit 14 . An LG (Light Guide) connector 20 is provided at the tip of the universal cable 18 . The LG connector 20 is detachably connected to a light source device (not shown). As a result, illumination light can be sent from the light source device to the distal end of the insertion portion 12 via a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com