Automatic coconut peeler

A coconut peeling machine and automatic technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of manual operation danger, operator damage, and low production efficiency, so as to save labor, reduce labor costs, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

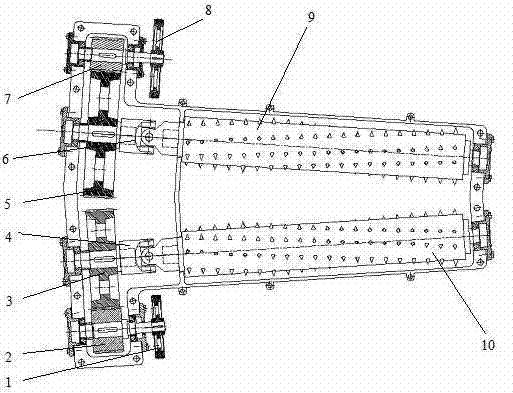

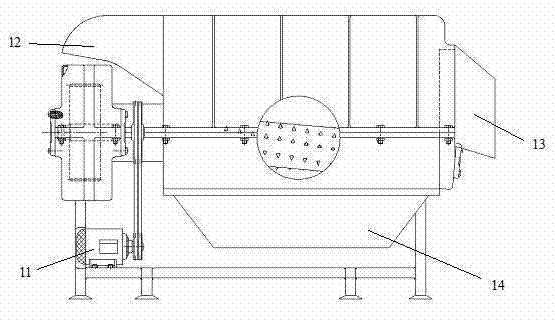

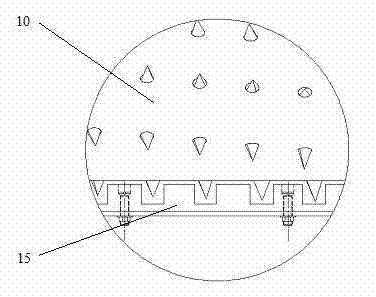

[0013] There is a material inlet 12, and the lower part of the material inlet 12 is provided with rollers 9 and 10, and nail rake teeth are arranged on the rollers 9 and 10. On the contrary, the drums 9, 10 are inclined at a certain angle to the horizontal plane, and the drums 9, 10 are inclined at a certain angle, and the drums 9, 10 are driven by their respective drive motors through the belt drive pulleys 8, 1, pinion gears 7, 2, and large gears 5, 3 And universal joint 6,4 drives rotation, and the afterbody of cylinder 9,10 is provided with discharge opening 13, and the bottom of cylinder 9,10 is provided with coconut coat removal device 15, and the bottom of coconut coat removal device 15 is provided with coconut coat discharge Mouth 14.

[0014] Coconut with coconut coat is put into feeding port 12, under the effect of gravity, coconut enters between cylinder 9,10, starts the drive motor of cylinder 9,10, cylinder 9,10 is rotated oppositely, because cylinder 9, There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com