A voltage fault monitoring system and method for an electron irradiation accelerator

A technology of voltage fault and electron irradiation, which is applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve the problems of the voltage detection system being bulky, unable to accurately locate the fault location, and unable to detect the voltage of key parts, so as to facilitate the diagnosis of accelerator work. environment, easy maintenance, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

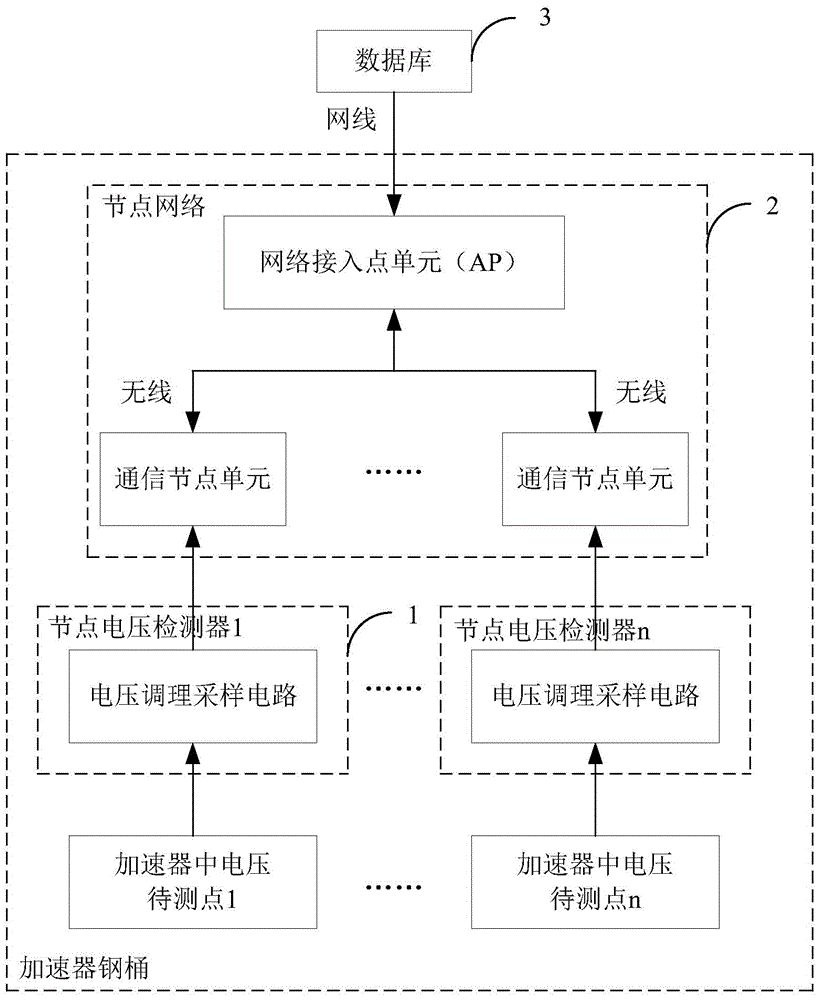

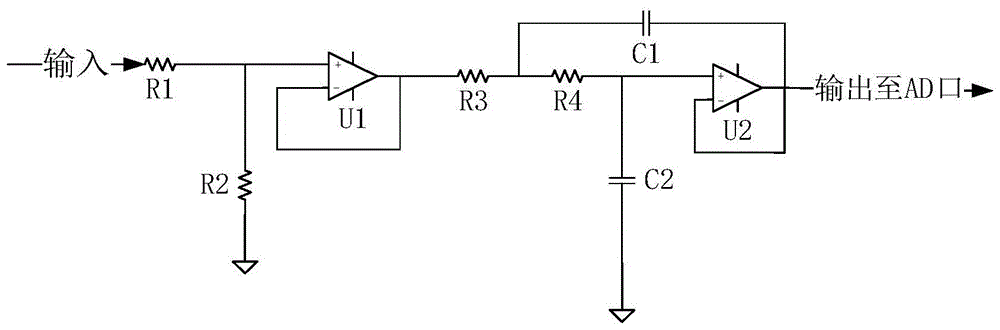

[0024] The present invention adopts distributed measurement; if wireless communication is used to complete the measurement, the coupling of the DC high voltage and the communication signal can be released, and a lower relative voltage can be directly measured at a suspended high potential without the need for a huge distribution piezoresistor stack. Based on this idea, the present invention proposes a distributed measurement system. By arranging voltage measurement nodes at key points of the accelerator (positions that are prone to high-voltage ignition and high failure rate points in the accelerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com