Automatic coded disk component testing platform and operation method thereof

An automatic test and test platform technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of poor inspection effect, inability to detect whether there are dirty spots, scratches, difficulty in finding tiny dirty spots and scratches on the code disk, etc. accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

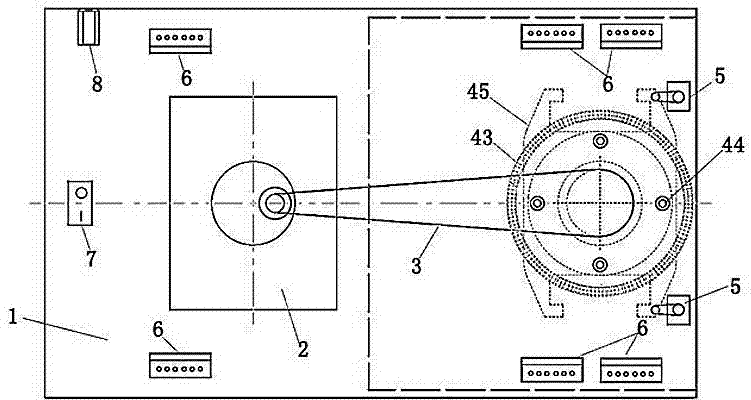

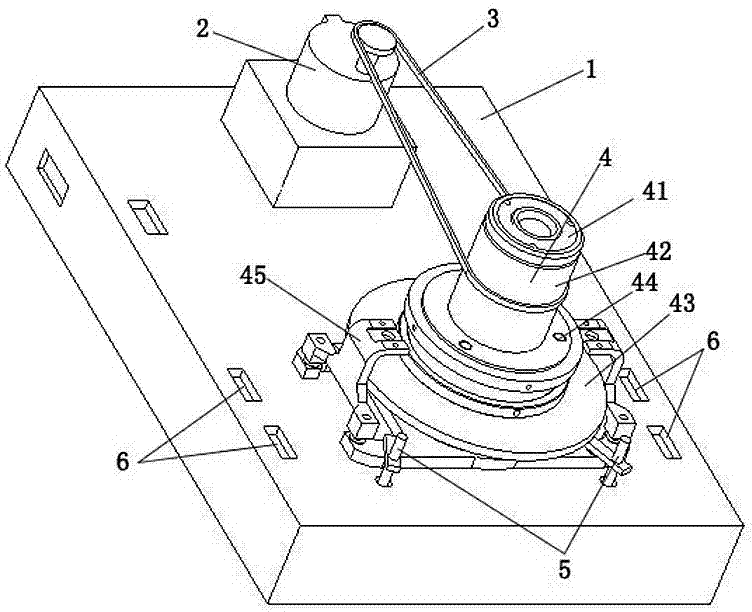

[0019] This embodiment is an automatic test platform for code disc components, which includes: a base (1), a stepping motor (2), a transmission belt (3), a detection device (4), a communication interface (6), a power switch (7 ), DC power socket (8).

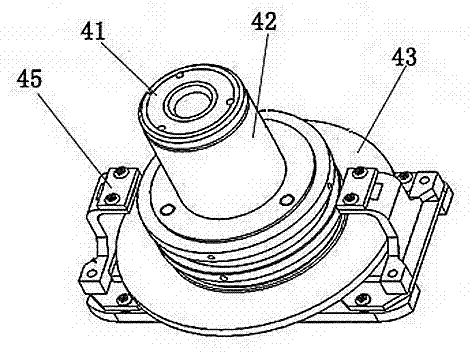

[0020] Such as figure 1 , figure 2 As shown, the left side of the base (1) is provided with a stepping motor (2), and the right side is provided with a detection device (4) for detecting dirty spots on the code disc. The detection device (4) includes: a fixed shaft (41), transmission shaft (42), code disc assembly positioning hole (44), CCD board assembly (45), code disc assembly positioning buckle (5), the fixed shaft (41) and transmission shaft (42) A shaft system is formed, the transmission shaft (42) is sleeved on the fixed shaft (41), the code disc to be tested (43) is fixed on the transmission shaft (42), and the CCD board group (45) is fixed on the fixed shaft (41) Above, the bottom of the fixed shaft (41) is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com