Constructing method of large equipment mounting pit foundation

A large-scale equipment and construction technology, applied in construction, excavation, infrastructure engineering and other directions, can solve the problems of inconvenient equipment disassembly, prone to landslide safety accidents, and heavy workload of earthwork, so as to avoid landslide accidents, small workload, The effect of less earthwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

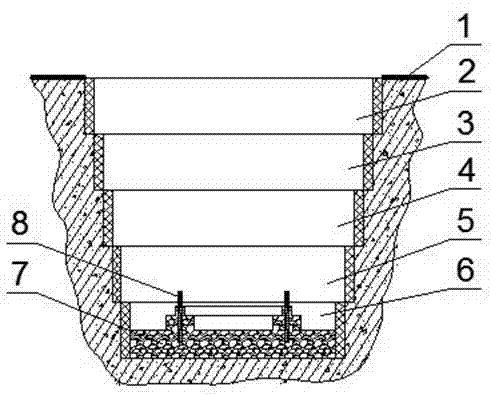

[0009] exist figure 1 In the middle, excavate an egg-shaped shallow pit on the ground 1, and then use steel mold prefabricated concrete to build the negative layer of egg-shaped pit wall 2, and continue to excavate the second layer of egg-shaped pit wall 2 in the negative layer of egg-shaped pit wall. shallow pit, and then use steel mold prefabricated concrete to construct the egg-shaped pit wall 3 on the negative second floor; Negative three-layer egg-shaped pit wall 4, continue to excavate the fourth layer of egg-shaped shallow pit downwards in the negative three-layer egg-shaped pit wall 4, and then use steel mold prefabricated concrete to form negative four-layer egg-shaped pit wall 5, continue to Excavate the fifth egg-shaped shallow pit downwards in the negative four-story egg-shaped pit wall 5, and then use steel molds to precast concrete to form a negative five-story egg-shaped pit wall 6, and pour reinforced concrete in the negative five-story egg-shaped pit wall 6 F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com