Method for controlling height of material layer of bin of two-sided jet-type charging machine

A control method and spray technology, which are applied in the manufacture of cigarettes, applications, tobacco, etc., can solve the problems of cigarettes and material liquid easily sticking to the warehouse wall, large vacuum damping, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

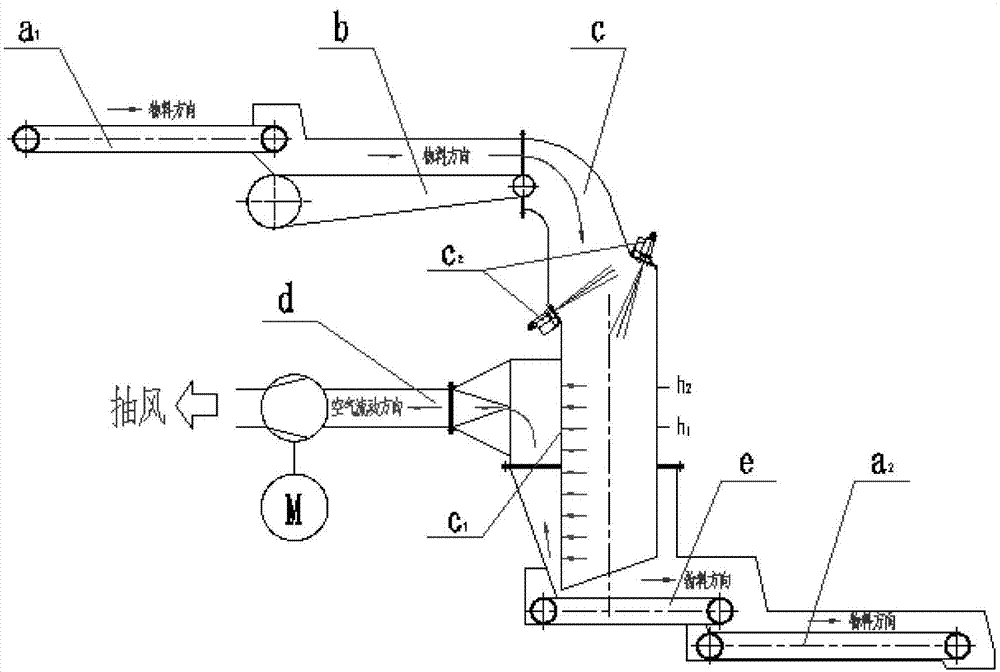

[0009] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0010] figure 1 As shown, a control method for controlling the height of the bin material layer of a double-sided jet feeder, the present invention is characterized in that a metering belt scale is respectively placed at the feed and discharge places of the double-side jet feeder, and by The weight of the incoming and outgoing materials is calculated by calculating the cumulative weight difference of the two belt scales at the same time (excluding the weight of the liquid fed through the mass flow meter) to calculate the weight of the materials accumulated in the feeding bin at that time, and then according to the weight of the materials Bulk density (the bulk density of the material can be weighed according to the actual stacking height by using the container at the same height to calculate the bulk density ρ close to the actual situation. Generally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com