Turbo compressor system having at least two driving motors

A technology for driving electric motors and turbo compression, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc. It can solve the problems of the overall efficiency reduction of the turbo compression system, achieve excellent cooling efficiency, solve space constraints, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, various embodiments of a turbo compression system according to the present invention will be described with reference to the accompanying drawings.

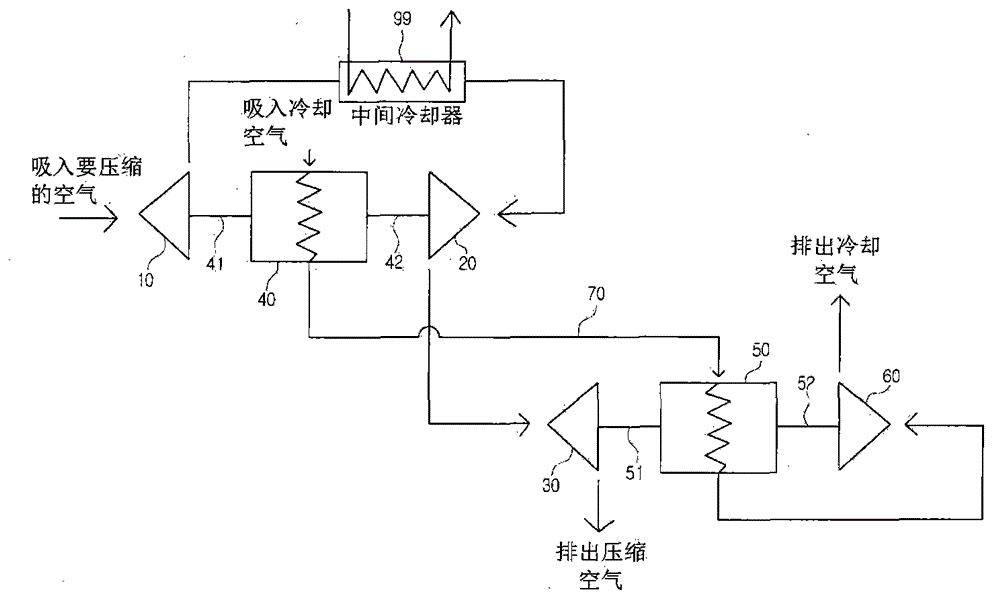

[0028] figure 1 is a view of a turbocompression system with two or more drive motors according to a first embodiment of the present invention.

[0029] refer to figure 1 , according to the first embodiment of the present invention, the turbocompression system with two or more drive motors includes: a first impeller 10, a second impeller 20, a third impeller 30, a drive comprising a first motor 40 and a second motor 50 Motor, and cooling impeller 60.

[0030] The first impeller 10 is connected to a rotation shaft 41 arranged on one side of the first motor 40 and rotates, and the second impeller 20 is connected to a rotation shaft 42 arranged on the other side of the first motor 40 and rotates.

[0031] In this case, an intercooler 99 may be installed between the first impeller 10 and the second impeller 20 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com