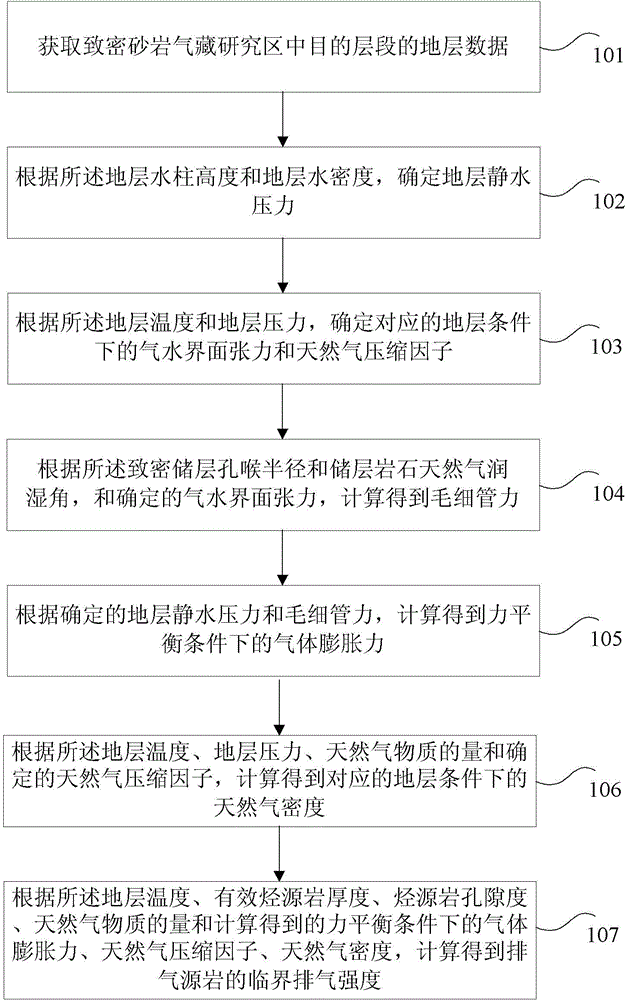

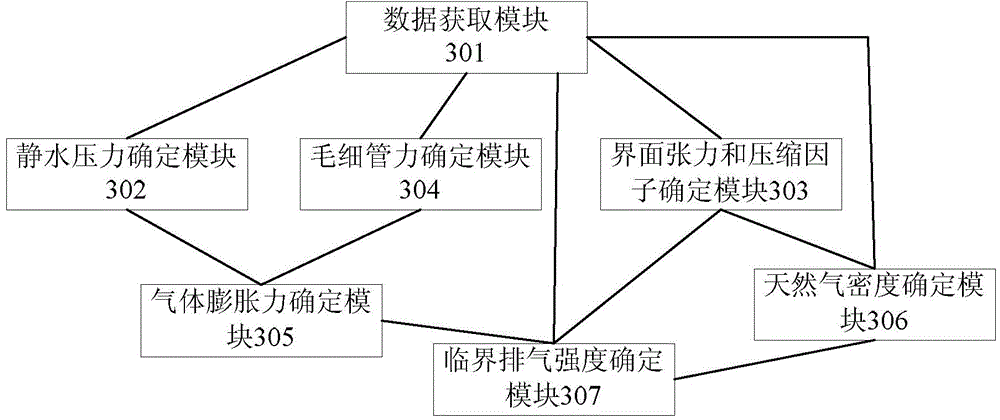

Method and device used for determining critical exhaust strength of tight sandstone gas reservoir exhaust source rocks

A technology of tight sandstone gas reservoir and density, applied in the field of oil and gas exploration, can solve the problem of difficult quantitative prediction of critical exhaust intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

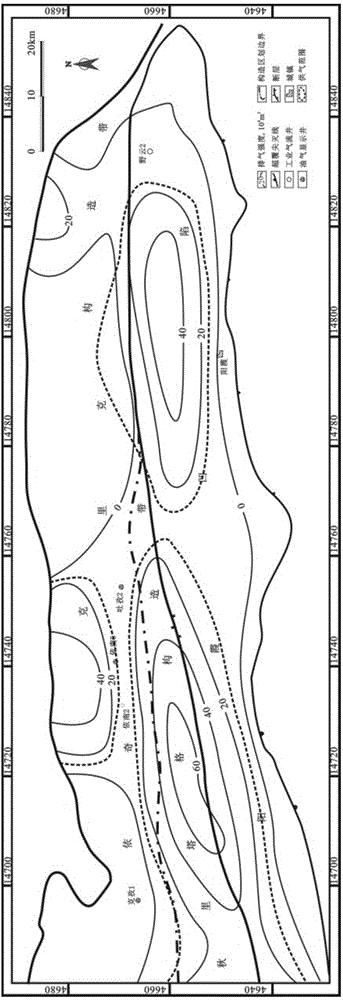

[0066] The inventors considered the force balance condition in the process of filling the pore throats of tight reservoirs with the natural gas generated in the source rock: when the natural gas generated in the source rock reaches a certain amount, the gas expansion force generated is sufficient to overcome the capillary force and the upper Overlying water column pressure, establishing a method to determine the critical venting strength of effective gas source rocks, so as to determine the critical venting strength of natural gas charging into tight reservoirs under different burial depths, formation temperatures, and pressures, so as to solve the problem of tight sandstone gas The problem of quantitative evaluation of whether the gas source rocks have gas supply availability provides an accurate and feasible method for predicting the critical hydrocarbon expulsion strength of effective gas source rocks in tight gas reservoirs, and then can determine the total amount of gas sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com