Self-balancing shaft bucket type continuous hoisting system hopper

A lifting system and self-balancing technology, applied in the field of hoppers, can solve the problems of easy tripping, not very reliable, tilting hoppers, etc., and achieve the effect of high stability and safety, low cost and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

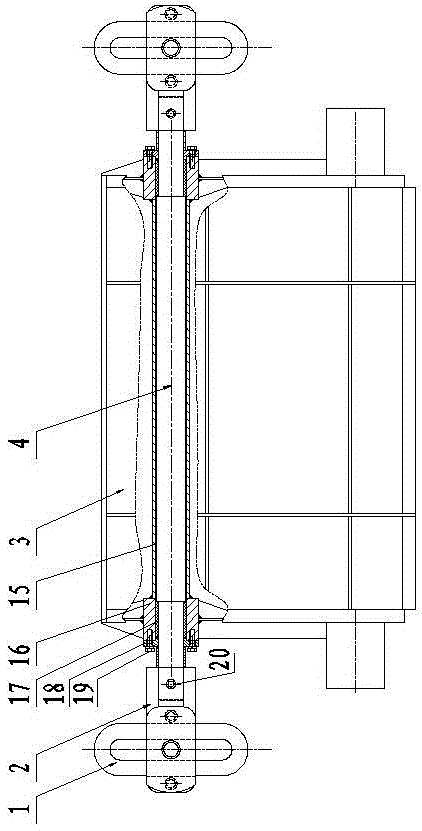

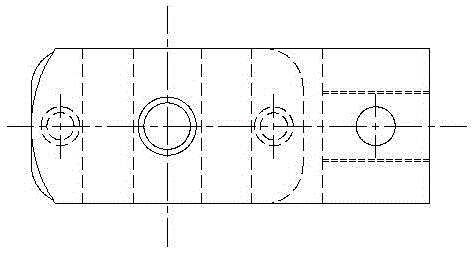

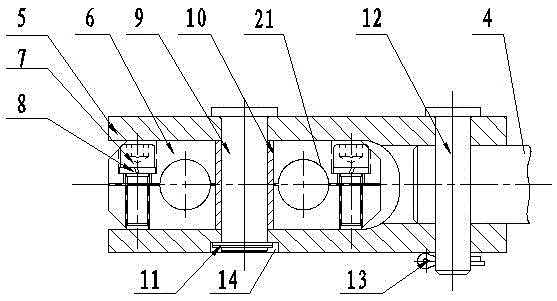

[0013] Such as Figure 1-3 As shown, the hopper of the self-balancing vertical shaft bucket type continuous hoisting system includes a hopper body 3 with a circular chain connecting shaft on the hopper body 3. The connecting shaft is a through shaft 4 with a floating balance function at both ends. The through shaft 4 is installed inside the hopper body 3, and its two ends protrude from the left and right side walls of the hopper body 3. Two parallel circular chains 1 is connected to both ends of the through shaft 4 through two sets of chain-holding balance connecting devices 2 respectively.

[0014] Such as figure 2 , 3 As shown, each set of chain holding balance connection device 2 is composed of handle 5, chain holding device 6, pin shaft I12, cotter pin 13, pin shaft II9, copper sleeve 10 and shaft elastic retaining ring 11, and chain holding device 6 is composed of two Grab arm, two screws 7 and two spring washers 8; the catcher 5 is connected with one end of the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com