Guided tissue regeneration membrane as well as preparation method and application thereof

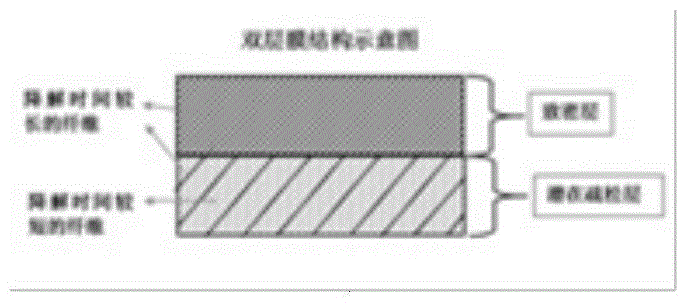

A technology for guiding tissue regeneration and double-layer membrane, which is used in chemical instruments and methods, medical science, cellulose plastic material layered products, etc. To achieve the effect of promoting the formation of new tissue, conducive to cell ingrowth, and wide clinical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 A kind of preparation method of guided tissue regeneration film

[0047] 1. Dosing

[0048] Dissolve collagen and polylactic acid (PLA) in hexafluoroisopropanol (HFIP) according to the mass ratio of 1:9, and the ratio of material to liquid is 1:10, and stir until completely dissolved to obtain uniform spinning with a long degradation time Liquid(Z);

[0049] Dissolve collagen and polylactic acid (PLA) in hexafluoroisopropanol (HFIP) at a mass ratio of 9:1, with a material-to-liquid ratio of 1:10, and stir until completely dissolved to obtain uniform spinning with a short degradation time Liquid (Q).

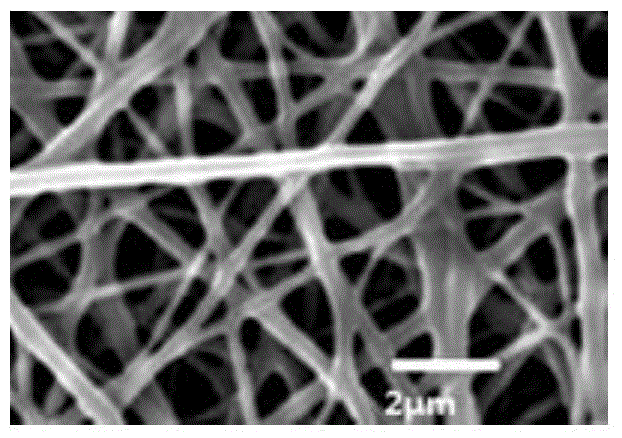

[0050] 2. Spinning dense layer

[0051] Put the above spinning solution Z into the electrospinning syringe, adjust the rate of the micro-injection pump to 5ml / hour, the voltage of the electrospinning machine to 20KV, adjust the receiving distance of the receiving device to 20cm, and stop spinning after reaching a thickness of 0.1mm , quickly enter the next...

Embodiment 2

[0056] Embodiment 2 A kind of preparation method of guided tissue regeneration film

[0057] 1. Dosing

[0058] Dissolving gelatin and silk fibroin in trifluoroethanol at a mass ratio of 2:8, with a solid-liquid ratio of 1:20, stirring until completely dissolved to obtain a uniform spinning solution (Z) with a long degradation time;

[0059] Dissolve gelatin and silk fibroin in trifluoroethanol at a mass ratio of 8:2, with a solid-to-liquid ratio of 1:20, and stir until completely dissolved to obtain a uniform spinning solution (Q) with a short degradation time.

[0060] 2. Spinning dense layer

[0061] Put the above spinning solution Z into the electrospinning syringe, adjust the rate of the micro-injection pump to 0.5ml / hour, the voltage of the electrospinning machine to 10KV, adjust the receiving distance of the receiving device to 10cm, and stop spinning after reaching a thickness of 0.1mm. Silk, quickly enter the next step;

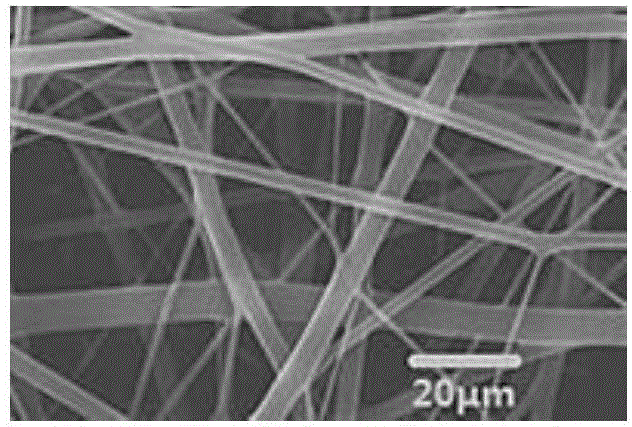

[0062] 3. Spinning potential loose layer

...

Embodiment 3

[0066] Embodiment 3 A kind of preparation method of guided tissue regeneration film

[0067] 1. Dosing

[0068] Chitosan and polylactic-glycolic acid (PLGA) are dissolved in formic acid according to the ratio of mass ratio 3:7, and the ratio of solid to liquid is 1:5, and stirred until completely dissolved to obtain a uniform spinning solution with a long degradation time (Z );

[0069] Chitosan and polylactic-glycolic acid (PLGA) are dissolved in formic acid according to the ratio of mass ratio 7:3, and the ratio of solid to liquid is 1:5, and stirred until completely dissolved to obtain a uniform spinning solution with a shorter degradation time (Q ).

[0070] 2. Spinning potential loose layer

[0071] The above-mentioned spinning solution Z and spinning solution Q are respectively packed in the electrospinning injectors Z and Q, the injection flow rate of the adjustment injector Z is 0.1ml / hour, and the ratio of the injection flow rate of the adjustment injector Q to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com