Inward-shrinking glue reinforcing sheet production device

A production device and reinforcing sheet technology, applied in mechanical/acoustic circuit processing, electrical components, printed circuit manufacturing, etc., can solve the problems of many production links and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

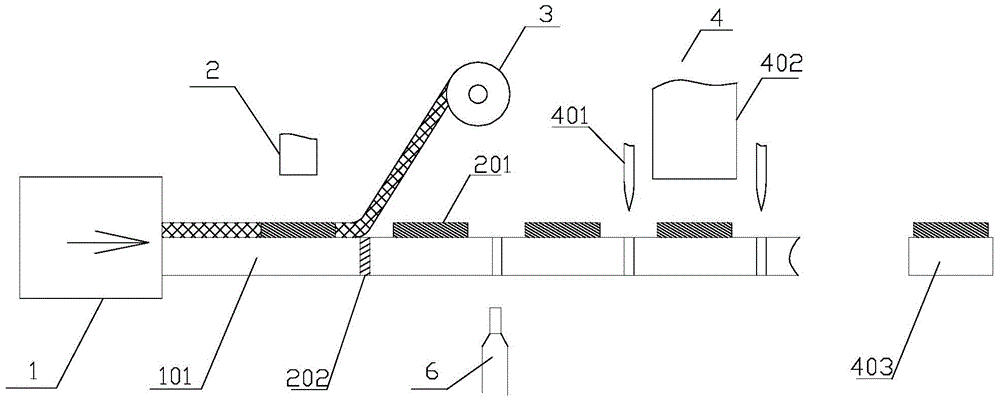

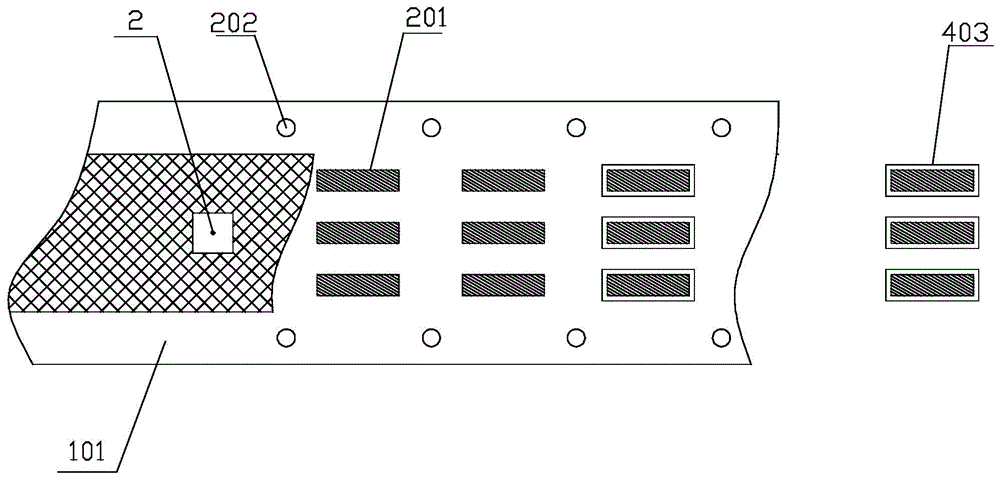

[0011] like figure 1 and figure 2 The rubber-coated steel belt film changing device shown includes: a rubber-coated steel belt conveying unit 1 , a laser cutter 2 , a waste rewinding unit 3 and a product punching unit 4 .

[0012] The rubber-coated steel belt conveying unit 1 continuously conveys the rubber-coated steel belt 101; the laser cutter 2 is aligned with the rubber-coated surface of the rubber-coated steel belt 101, and is used to cut out the molding glue 201 and the positioning hole 202; After the cutter 2, it is used for rewinding the waste of molding rubber 201; the product punching unit 4 is located on the rear side of the waste rewinding unit 3, and is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com