Optical fiber face plate fractal filament arranging method and filament arranging dies thereof

An optical fiber panel and mold technology, which is applied in the direction of beam optical fibers, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of reducing the service life of the picture tube, the gap of the multi-filament boundary unit filament, affecting the image clarity and air tightness, etc. Achieve improved clarity and tightness, improved performance and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

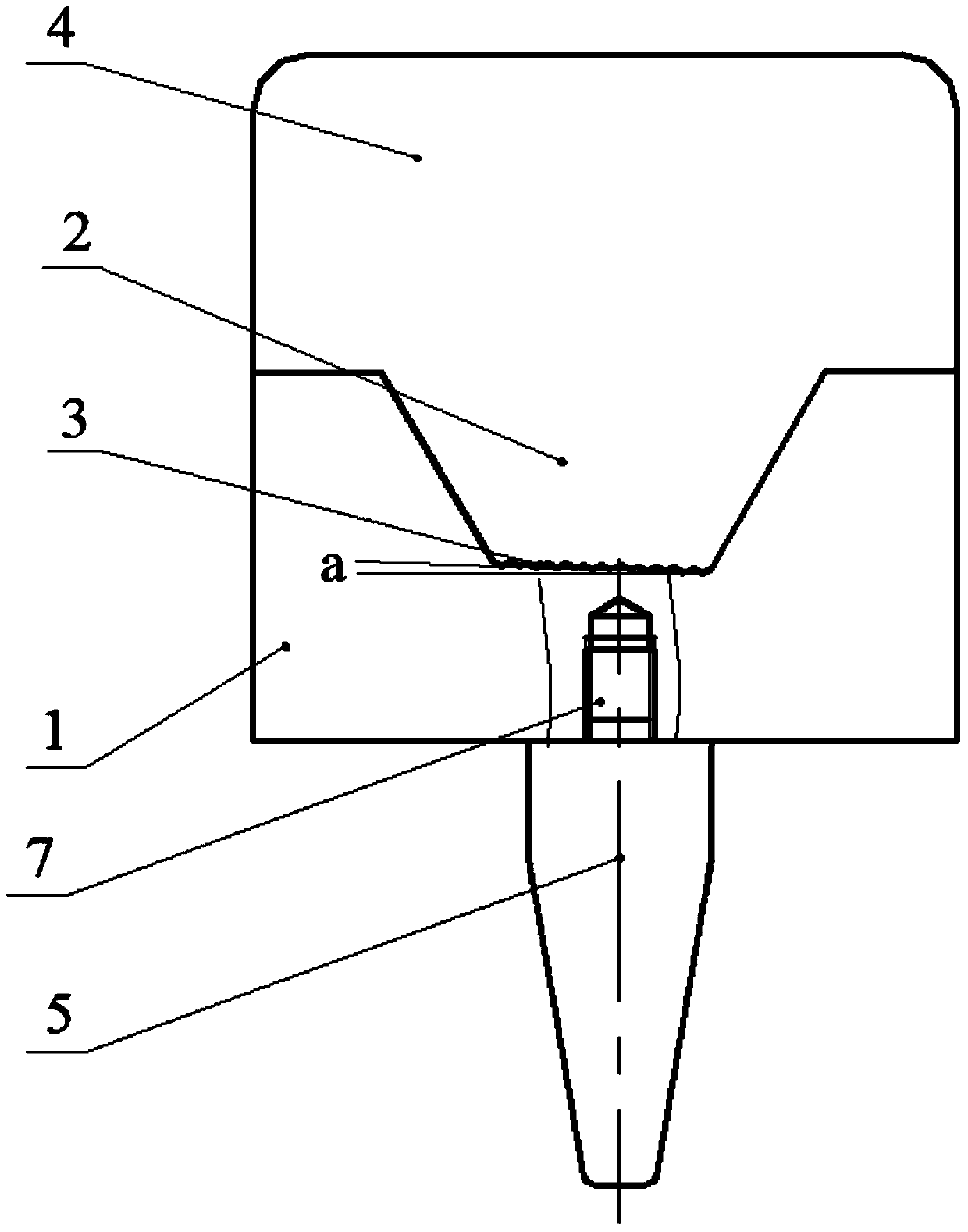

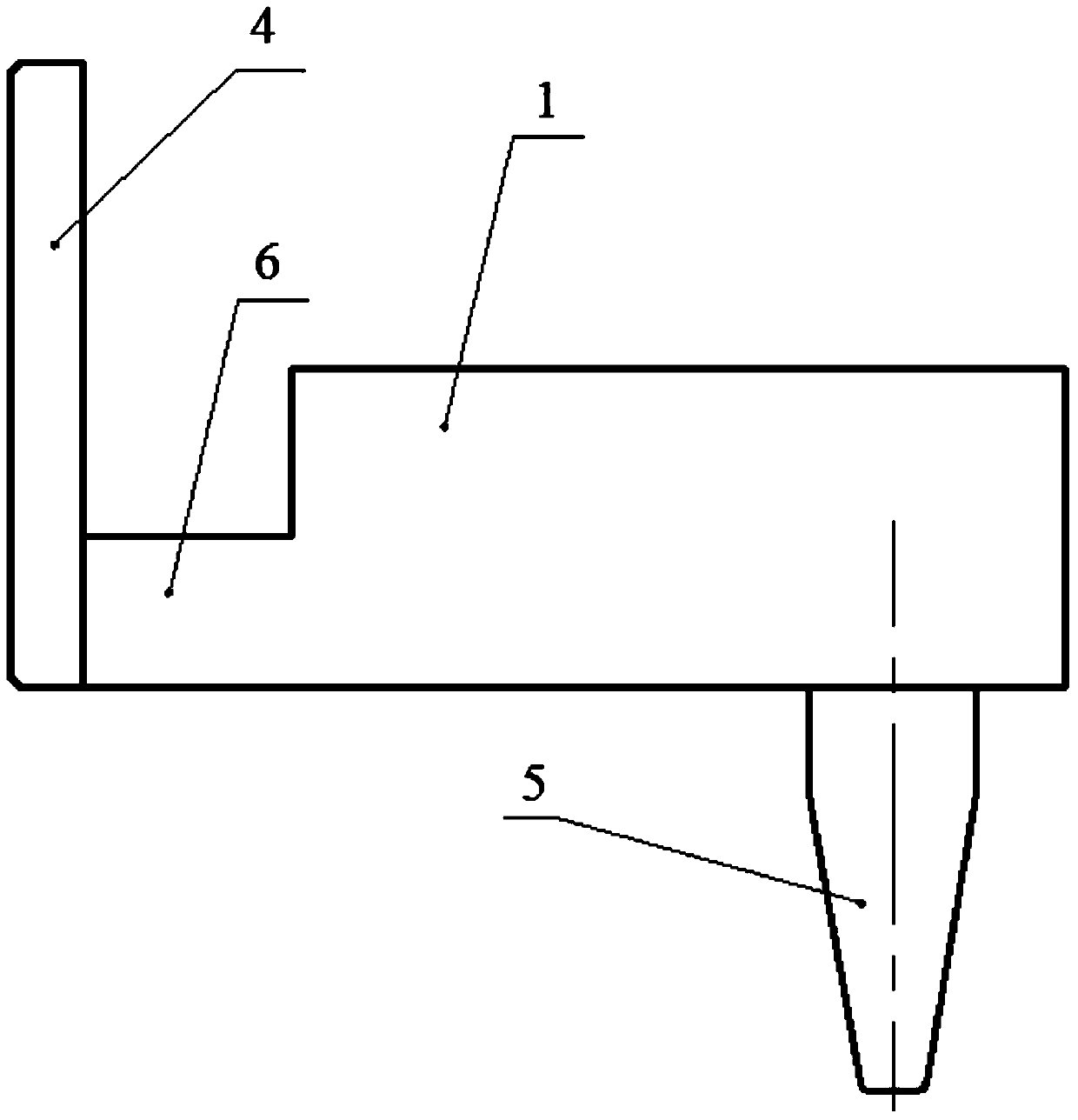

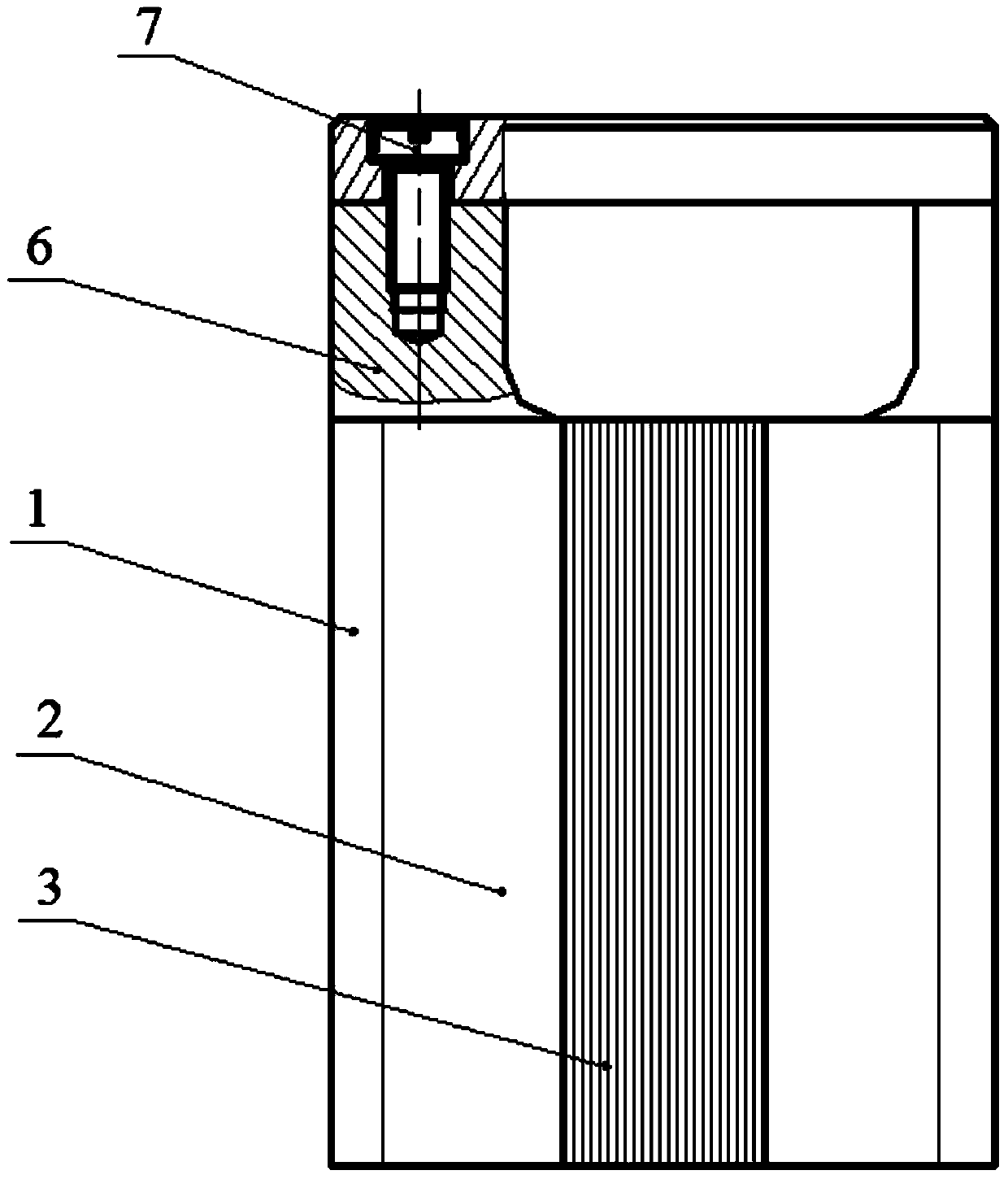

[0045] A fractal wire arrangement method for an optical fiber panel, the method comprising:

[0046] (1) drawn monofilament

[0047] Put the matched rod and tube combination into the wire drawing machine for the first wire drawing to obtain monofilament;

[0048] (2) Arranging a composite rod and drawing a composite wire

[0049] Carry out the first wire drawing of the monofilament to obtain the primary composite rod, put the primary composite rod into the wire drawing machine for the second wire drawing, and obtain the primary composite wire;

[0050] (3) Arranging secondary composite rods and drawing secondary composite wires

[0051] Put the primary composite wires into the primary composite wire wire arranging mold for the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com