A Real-time Accurate Measurement Device of Specimen Volume Change in Ultra-Large Triaxial Test

A triaxial test and accurate measurement technology, applied in the measurement device, using stable tension/pressure to test the strength of materials, instruments, etc., to achieve high measurement accuracy, ensure accuracy, and solve high-precision measurement problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

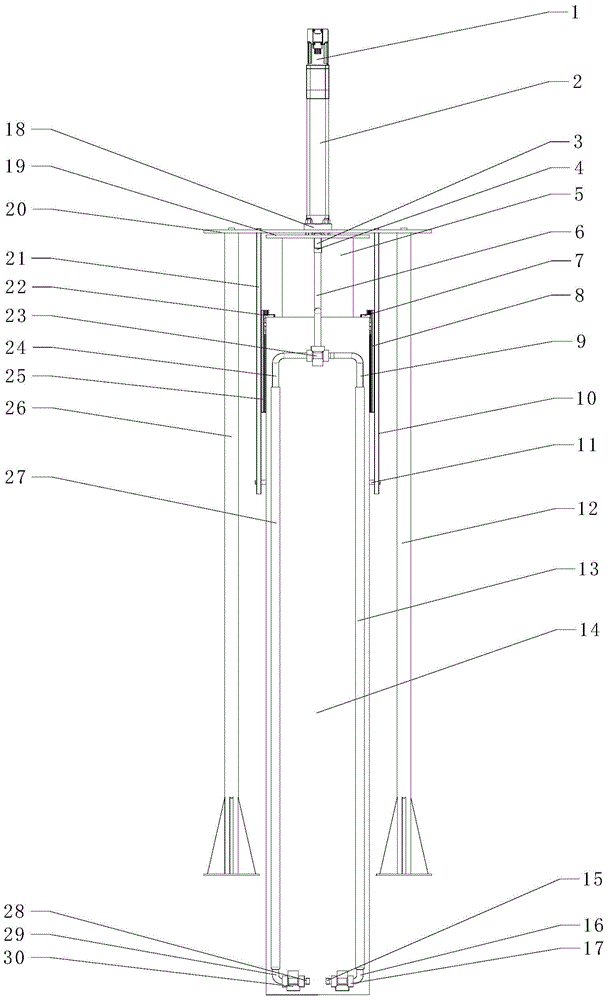

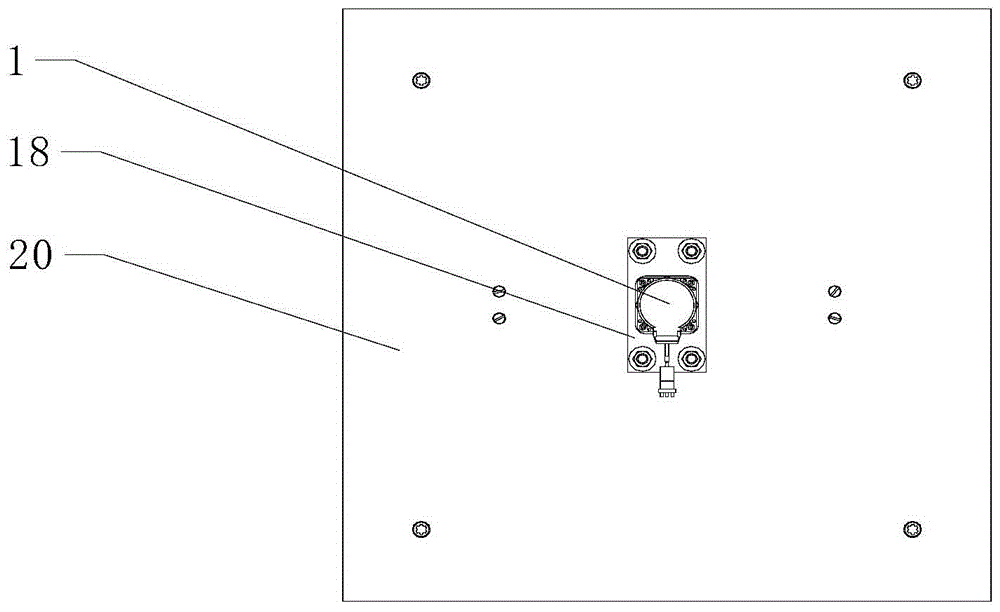

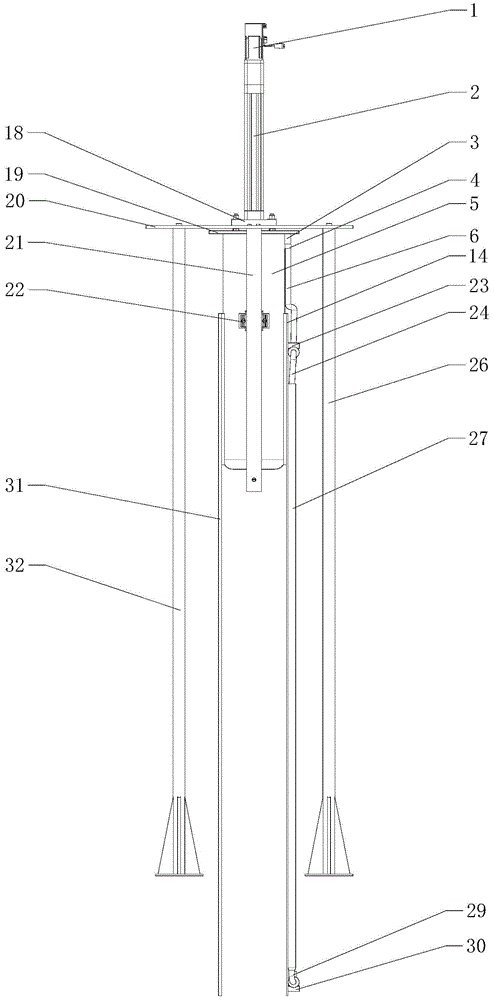

[0018] as attached Figure 1~4 As shown, the parts are cleaned with kerosene during assembly, and the mating surface is oiled after drying. The unprocessed surface of each part should be cleaned, the burrs should be removed, and the anti-rust paint should be dipped; figure 1 It is composed of the dynamic adjustment subsystem of the height of the drain and the automatic continuous detection subsystem of the displacement. The system support column A12, the system support column B26, the system support column C32, and the system support column D33 are fixed on the ground, and support the dynamic adjustment subsystem of the fixed drain height. The right guide rail support plate 10 fixes the right guide rail 8, and the left guide rail support plate 21 fixes the left guide rail 25. Right slide block 7 and left slide blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com