Sealing performance testing device and method

A sealing performance and testing device technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., can solve problems such as product damage, and achieve convenient use, simple operation, and convenient sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

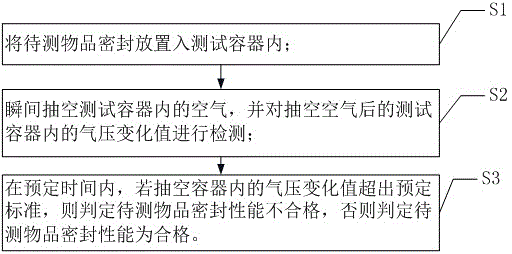

[0023] The present invention provides a sealing performance testing device and its testing method. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

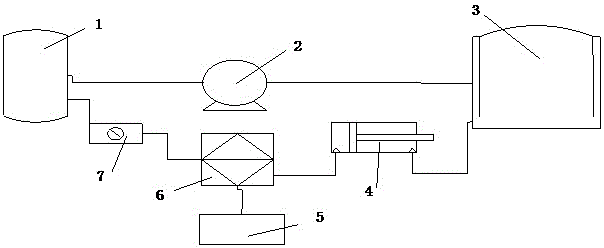

[0024] The invention provides a sealing performance testing device, such as figure 1 As shown, the test container 1, air pump 2, vacuum gas storage tank 3, air pressure controller 4, main controller 6 and the air pressure detector 7 used to detect the air pressure value in the test container are connected in sequence;

[0025] The article to be tested is sealed and placed in the test container 1, and the main controller 6 controls the air pump 2 and the vacuum air storage tank 3 by controlling the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com