Computing method of probe lifting heights of test probes of flying-probe tester

A flying probe testing machine and calculation method technology, which is applied to the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of reducing test efficiency, uneven clamping force, PCB deformation, etc. The effect of scraper probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

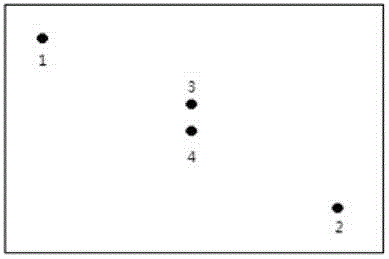

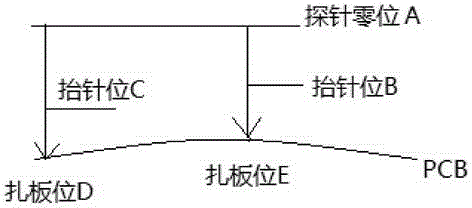

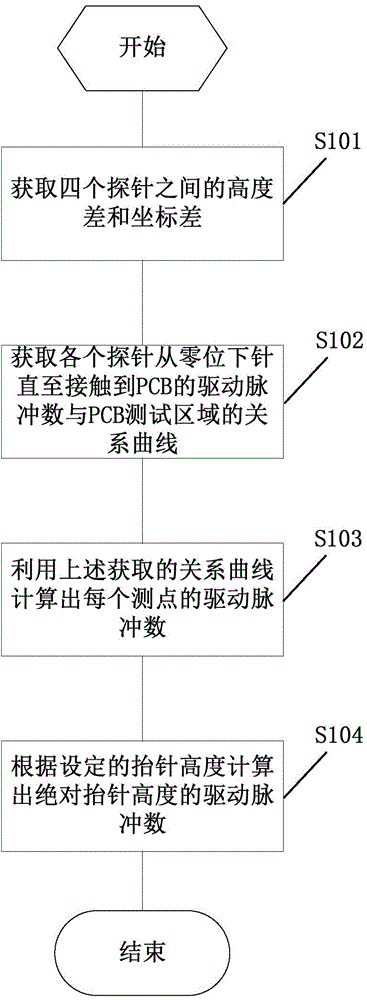

[0024] figure 1 Obtain position indications for the relationship curve test points of the calculation method of the needle lifting height in the present invention. figure 2 It is a schematic diagram of the position of the lower needle in the method for calculating the height of the needle raised in the present invention. image 3 It is a schematic flow chart of the method for calculating the needle lift height of the present invention.

[0025] see Figure 1 to Figure 3 , The present invention provides a method for calculating the lifting height of the test probe of a flying probe testing machine, which can take effective steps to reduce the probability of the probe scraper during the test while ensuring the test efficiency. The flying probe testing machine includes two probes for acting on the front of the PCB to be tested and two pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com