Stage lighting driving system and stage lighting using the system

A driving system and lighting technology, applied in lighting applications, devices used in theaters and circuses, parts of lighting devices, etc., can solve the problems of increased transportation costs, complicated installation, and occupying more space, and achieve internal structure The effect of large space, reduced manufacturing cost, and reduced internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

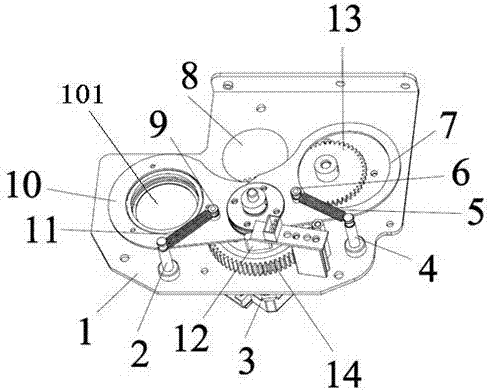

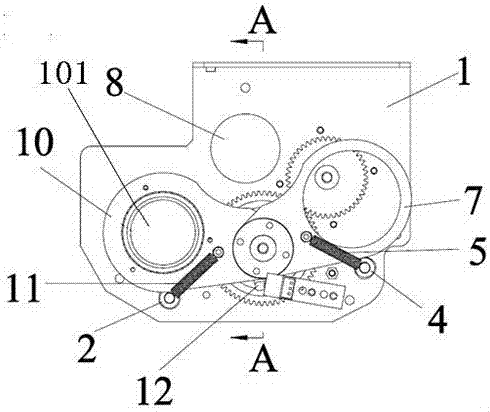

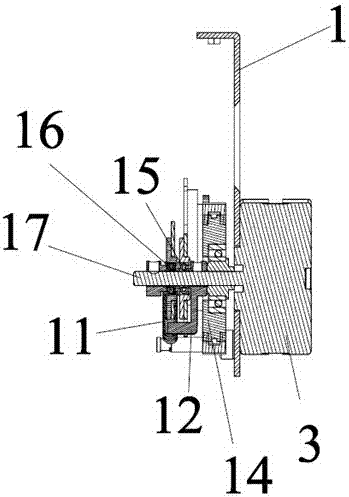

[0026] refer to Figure 1 to Figure 6 , the stage lighting driving system includes a support 1, a driving motor 3, two optical element brackets 10 and an optical element bracket 7 (more optical element brackets can also be provided as required), the optical element bracket 10 and the optical element bracket 7 are respectively provided with a prism 101 and an atomizing mirror (not shown), and the prism 101 is rotatably mounted on the academic element bracket 10; the support 1 is provided with a light hole 8, and the two The optical element brackets 10 (and 7) are respectively arranged on both sides of the light-through hole 8; the drive motor 3 is installed on the support 1, and each optical element bracket 10 (and 7) passes through the bearing (or slip ring) 15 (and 16) are rotatably sleeved on the rotating shaft 17 of the driving motor 3, and the optical element brackets are arranged in staggered layers; the rotating shaft 17 of the driving motor 3 is fixedly connected with a...

Embodiment 2

[0029] This embodiment is similar to Embodiment 1, the difference is that the optical elements on the optical element holder 10 and the optical element holder 7 are all prisms 101, and the prisms 101 can be rotatably mounted on the optical element holders 10 and 7 , the rotation gears connected with the prism 101 are all meshed with the driven wheel 14 . The working principle of the stage lighting driving system and the prism rotation in this embodiment are similar to those in the first embodiment.

Embodiment 3

[0031] This embodiment is similar to Embodiment 1, and the difference is that the optical elements on the two optical element holders 10 and the optical element holder 7 are all atomized mirrors, and the two atomized mirrors are respectively non-rotatably mounted on the two optical element holders In 10 and 7, since the two atomized mirrors do not need to rotate, this embodiment can omit the rotation drive assembly for driving the rotation of the optical element. The working principle of the stage lighting driving system in this embodiment is similar to that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com