Single-ended led tubing lamp

A tube lamp, single-ended technology, applied in the direction of lampshade, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of energy consumption, loss of lamp holder, material loss, etc., and achieve the effect of convenient fixed installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

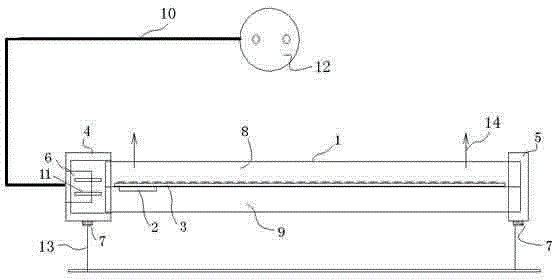

[0020] Such as figure 1 As shown, a single-ended LED tube lamp includes an LED lamp board 3, a lamp tube 1 and an LED lamp board power supply 2, the LED lamp board power supply 2 and the LED lamp board 3 are fixed in the lamp tube 1, and the two ends of the lamp tube 1 There are packaging heads, of which the left packaging head 4 has a power socket 6, the power cord 10 with the power plug 11 is inserted into the power socket 6, the power cord 10 is electrically connected to the power supply 12, and the LED light board is powered to drive the LED light Board work, the two ends of the packaging head each have a wire loop or wire tube 7 for fixing the light tube connection line 13 to pass through, the wire ring or wire tube 7 is opposite to the light emitting direction 14 of the LED lamp board, so as to facilitate fixed installation. The right sealing head 5 of the lamp tube is a sealed end cap. The lamp tube is composed of a PVC lampshade 8 and a semicircular pipe fitting 9 ext...

Embodiment 2

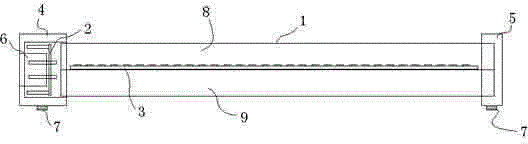

[0022] Such as figure 2 As shown, a single-ended LED tube lamp includes an LED lamp board 3, a lamp tube 1 and an LED lamp board power supply 2. The LED lamp board 3 is fixed in the lamp tube 1, and there are packaging heads at both ends of the lamp tube 1. The package head 4 has a power socket 6, the LED light board power supply 2 is fixed in the left package head 4, the AC input terminal of the LED light board power supply 2 is electrically connected to the 220 terminal of the power socket 6, and the power cord with the power plug 11 10 is inserted into the power socket 6, and the power cord 10 is electrically connected to the power supply 12. After the power supply of the LED lamp board is powered on, the LED lamp board is driven to work. Each of the two ends of the packaging head has a hole for fixing the connecting wire 13 of the lamp tube. Wire loop or wire conduit 7, wire loop or wire conduit 7 is opposite to the light emitting direction 14 of the LED lamp panel, so as...

Embodiment 3

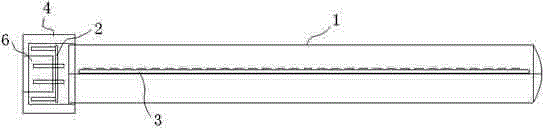

[0024] Such as image 3 As shown, a single-ended LED tube lamp includes an LED lamp board 3, a lamp tube 1 and an LED lamp board power supply 2, the LED lamp board power supply 2 and the LED lamp board 3 are fixed in the lamp tube 1, and the two ends of the lamp tube 1 There are packaging heads, of which the left packaging head 4 has a power socket 6, the power cord 10 with the power plug 11 is inserted into the power socket 6, the power cord 10 is electrically connected to the power supply 12, and the LED light board is powered to drive the LED light Board work, the encapsulation head at one end of the lamp tube is a structure that is processed into an integrated structure through a process when manufacturing the lamp tube, such as a glass tube manufacturing process and a plastic tube manufacturing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com