Gas turbine and method to operate the gas turbine

A technology of gas turbine and fluid path, which is applied in the direction of combustion method, gas turbine device, turbine/propulsion fuel delivery system, etc., to achieve the effects of stable control, cost reduction and system cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

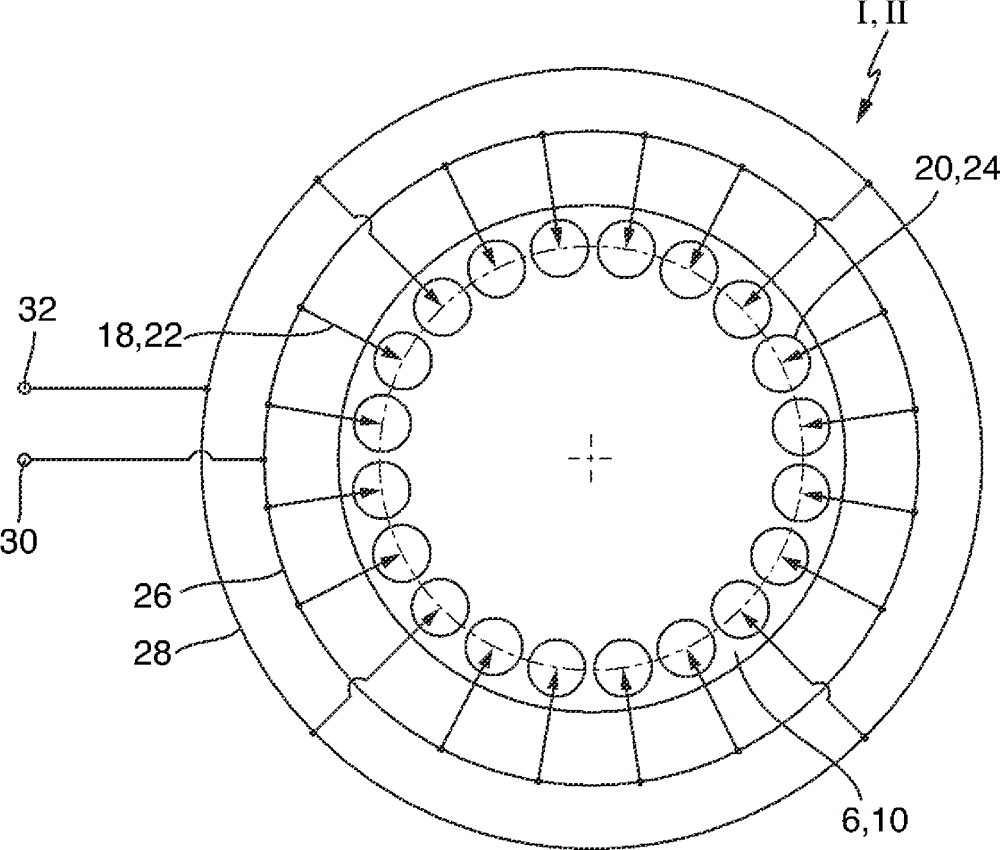

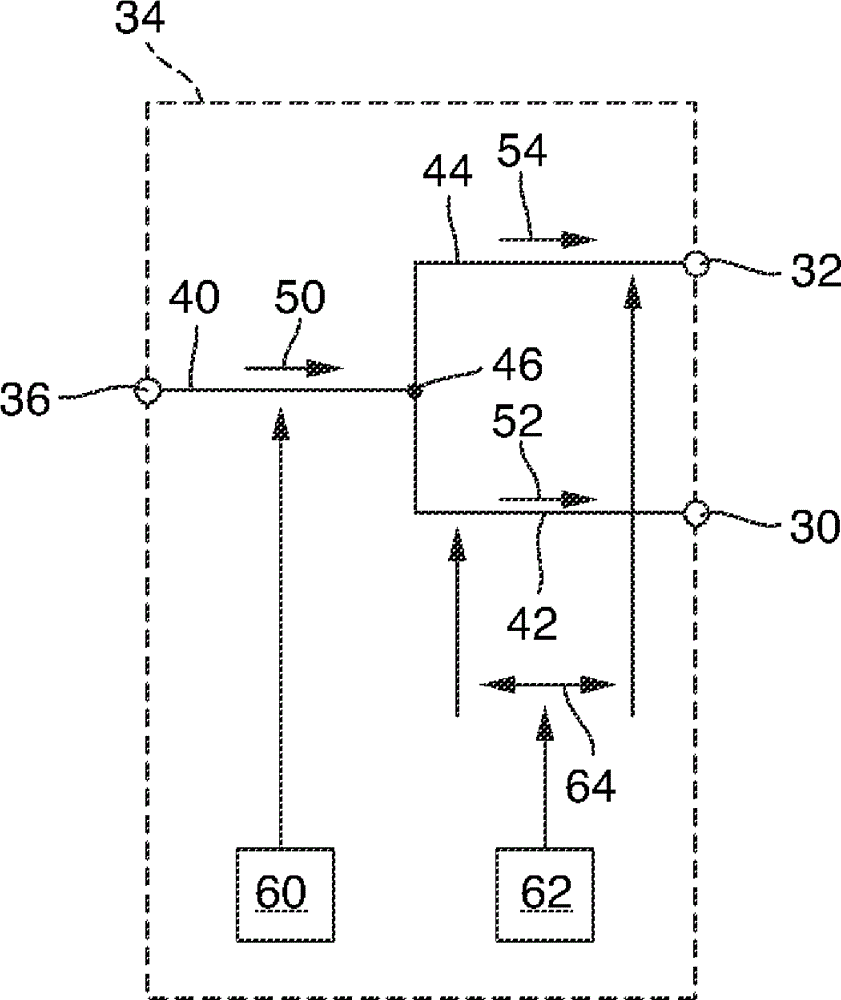

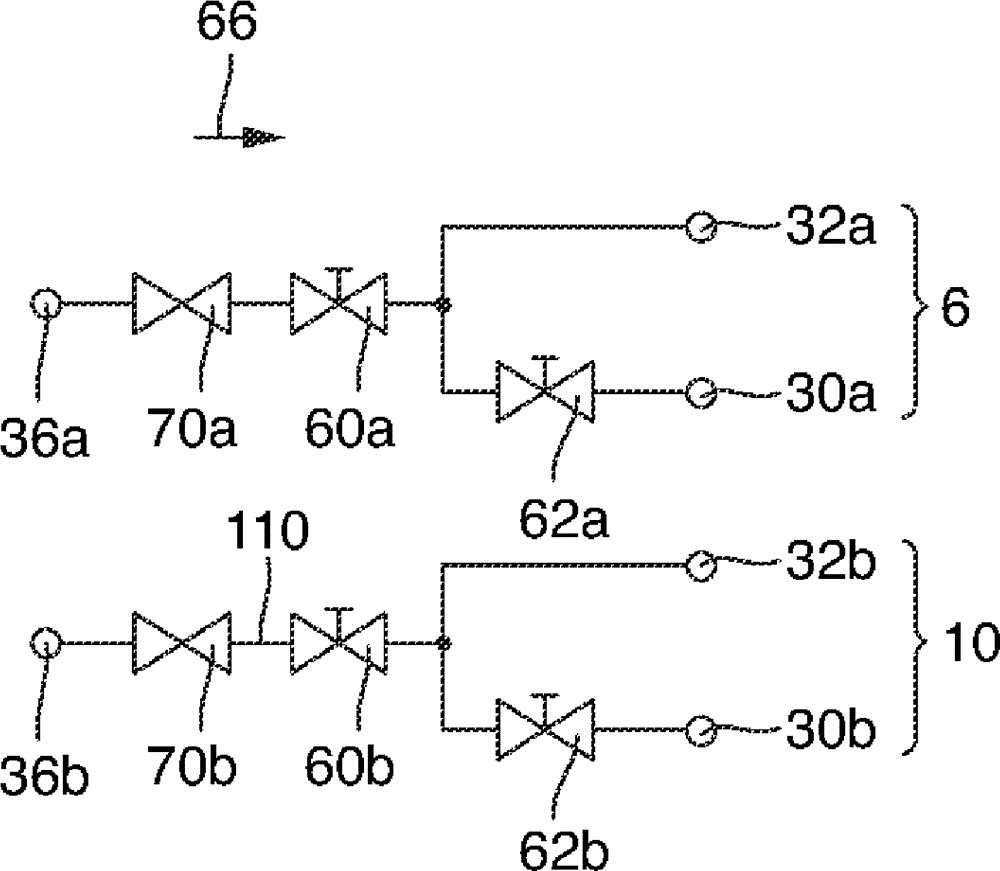

[0076] figure 1A gas turbine 2 with sequential combustion is shown schematically in an exemplary embodiment. The gas turbine 2 includes a compressor 4 , a first combustor 6 , a first turbine 8 , a second combustor 10 and a second turbine 12 . Typically, the gas turbine 2 includes a generator 14 arranged at the cold end of the gas turbine 2 , ie at the compressor 4 , coupled to a shaft 16 of the gas turbine 2 . Fuel, gas or oil is introduced via a fuel supply 18 to a burner 20 of the first combustor 6 , mixed with air compressed in the compressor 1 and combusted. The hot gases are partially expanded in the following first turbine 8 .

[0077] A fuel supply 22 supplies combustion fluid to a burner 24 of the second combustor 10 . The burners 20 of the first burner 6 are said to belong to a group. The burners 24 of the second burner 10 are said to belong to the second group. Groups 6 and 10 are therefore referred to using the reference numerals in a more general manner. Of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com