Spreading and cutting type digging bucket

A kind of excavator, prop-cutting technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of low work efficiency, poor active soil breaking ability, etc., to enhance the soil breaking ability, increase the gap, and improve the excavation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

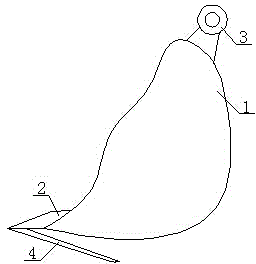

[0009] Such as figure 1 It is a schematic diagram of the structure of the present invention, a split excavator bucket, including a bucket body 1, shovel teeth 2 and lifting lugs 3, the shovel teeth 2 and lifting lugs 3 are respectively connected to the bottom and top of the bucket body 1, and the shovel teeth The bottom of 2 is provided with spring plate 4.

[0010] A spring plate 4 is set at the bottom of the shovel teeth 2. When inserted into the soil, the spring plate 4 is squeezed flat against the shovel teeth 2. After the insertion is in place and stopped, the spring plate 4 elastically expands to propel the soil downward, and at the same time push the shovel teeth 2. Lift up to increase the gap, prevent being sucked, enhance the ability of breaking ground, and greatly improve the excavation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com