Maintenance method for emergency gate of low-head gate dam and gate dam structure

A technology for accident gates and gate dams, which is applied in the maintenance field of low-head gate and dam accident gates in hydropower projects. The effect of removing the tie rod and overhauling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

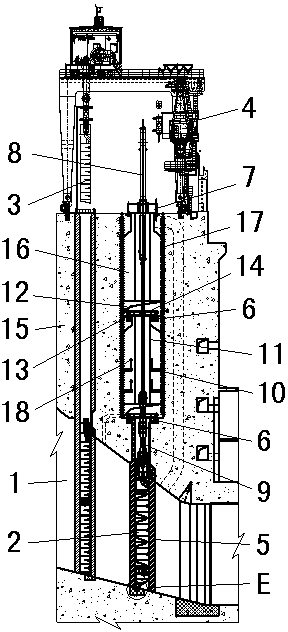

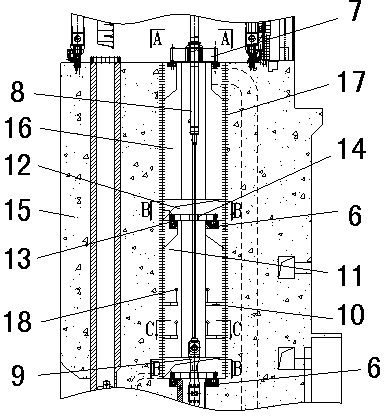

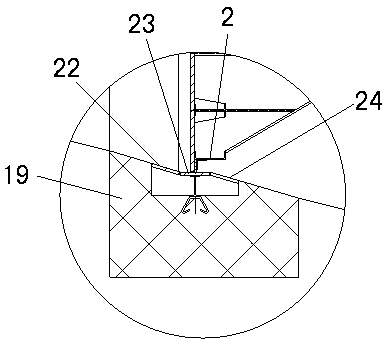

[0034] This example is for Figure 7 A modification of the prior art shown. Depend on Figure 6 It can be seen that there is no maintenance cavity 16 in the dam body 15 of the prior art, and the emergency gate 2 is lifted to the maintenance platform by the hoist 20 located on the dam surface and locked, and the fixed hoist 20 and the steel bent frame 21 are removed by the door crane, and then The emergency gate 2 is hoisted out of the dam surface for inspection and maintenance through the door operator 4; after the inspection is completed, the emergency gate 2 is locked on the inspection platform by the door operator 4, and then the hoist 20 and the steel bent frame 21 are installed and fixed. , all need to remove and install fixed winch 20 and steel bent frame 21 once, and maintenance is very troublesome.

[0035] The present invention as figure 1 As shown, the hydraulic cylinder 8 is used to replace the existing hoist 20 and steel bent frame 21. In order to reduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com