Side baffle floating mechanism for paver screed plate

A floating mechanism and side baffle technology, applied in roads, road repair, roads, etc., can solve the problems of high labor intensity, side baffle occupation, low paving efficiency, etc., to reduce labor intensity, high work efficiency, and improve The effect of paving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

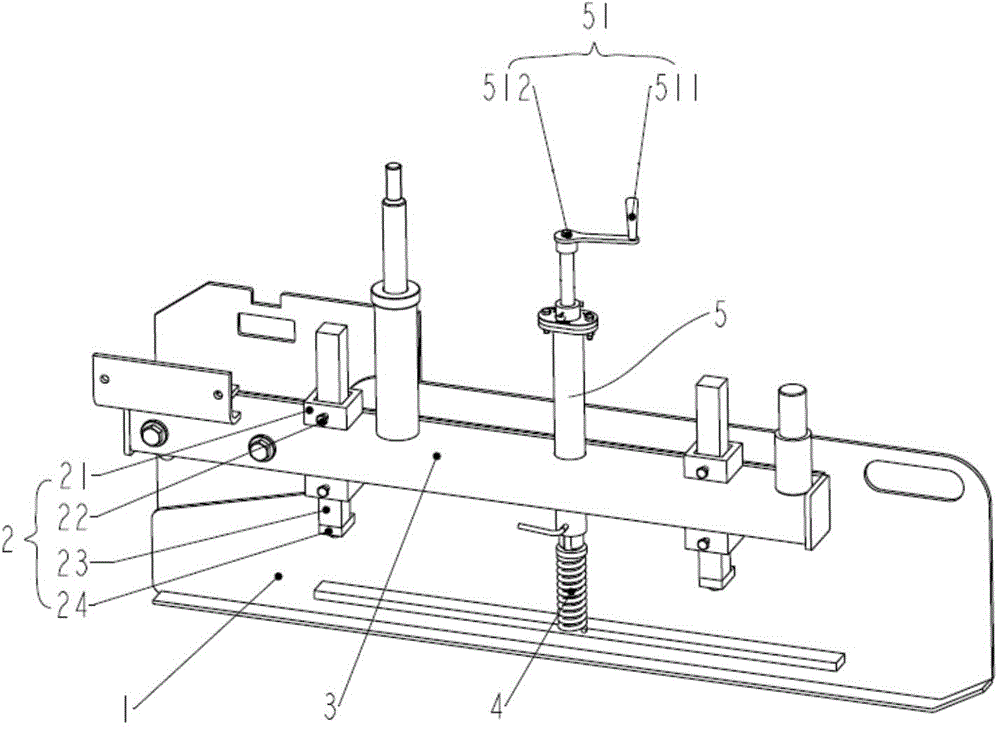

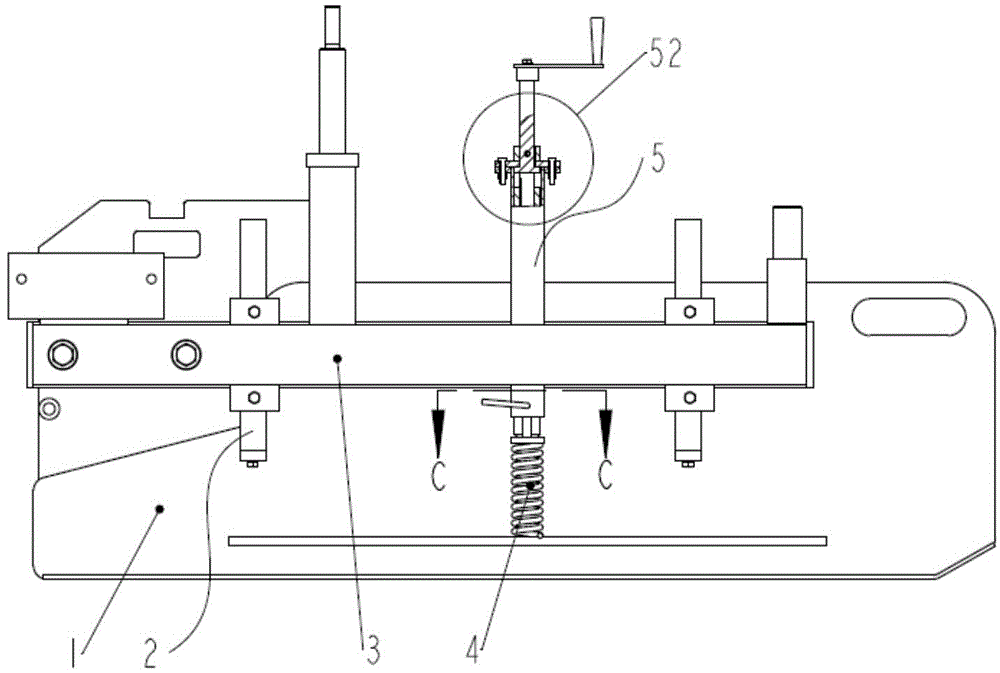

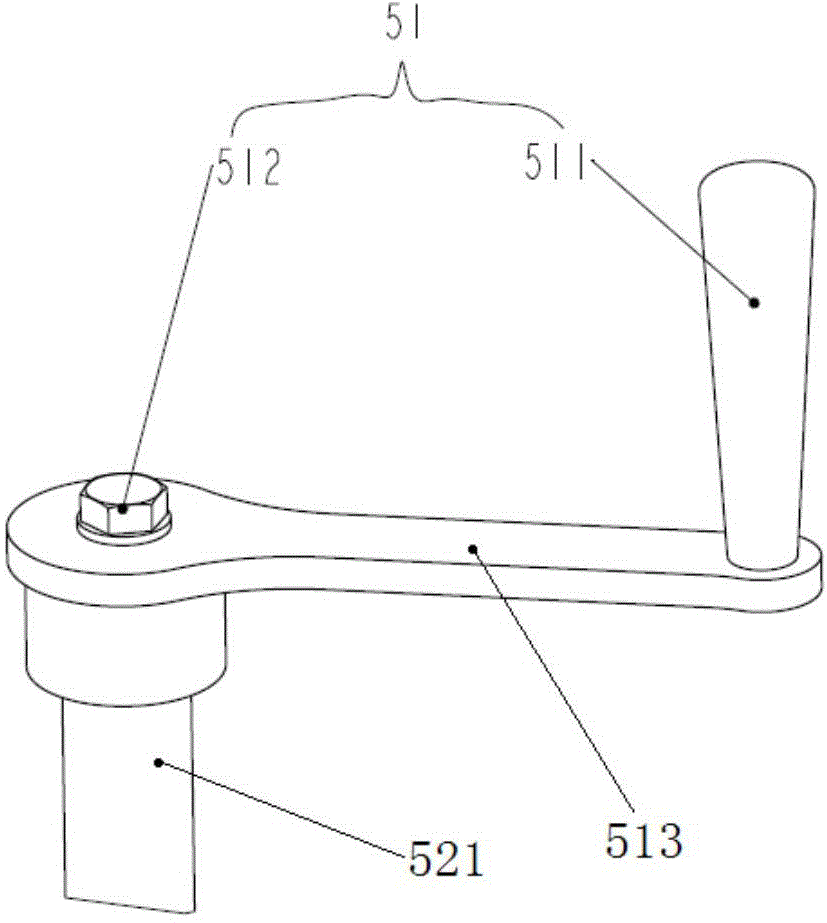

[0019] Figure 1 to Figure 5 As shown, it relates to a side fence floating mechanism for paver screed, including a bracket 3 arranged on the upper side, and a material stopper 1 arranged on the lower side of the bracket 3; The limiting part 2 that restricts the outward movement of the material blocking part 1; the lower part of the bracket 3 is provided with a floating spring 4 connected to the material blocking part 1, and the upper part of the bracket 3 is provided with a floating spring 4 connected to the floating spring 4. The spring 4 is connected to and drives the adjustment part 5 that the material blocking part 1 moves up or down.

[0020] Since the side baffle is equipped with a floating spring 4, if the side baffle encounters an obstacle during the paving operation, the side baffle can move upwards freely and cross the obstacle without stopping work or manually adjusting the material blocking part. Improve paving efficiency and reduce labor intensity. The floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com