Catalytic oxidation evaporation recovery system for mercerizing waste alkali liquid of yarn-dyed fabric

A technology of catalytic oxidation and waste lye, applied in the direction of alkali metal oxide/hydroxide, alkali metal compound, textile industry wastewater treatment, etc., to achieve the effect of improving efficiency, suppressing foaming phenomenon and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

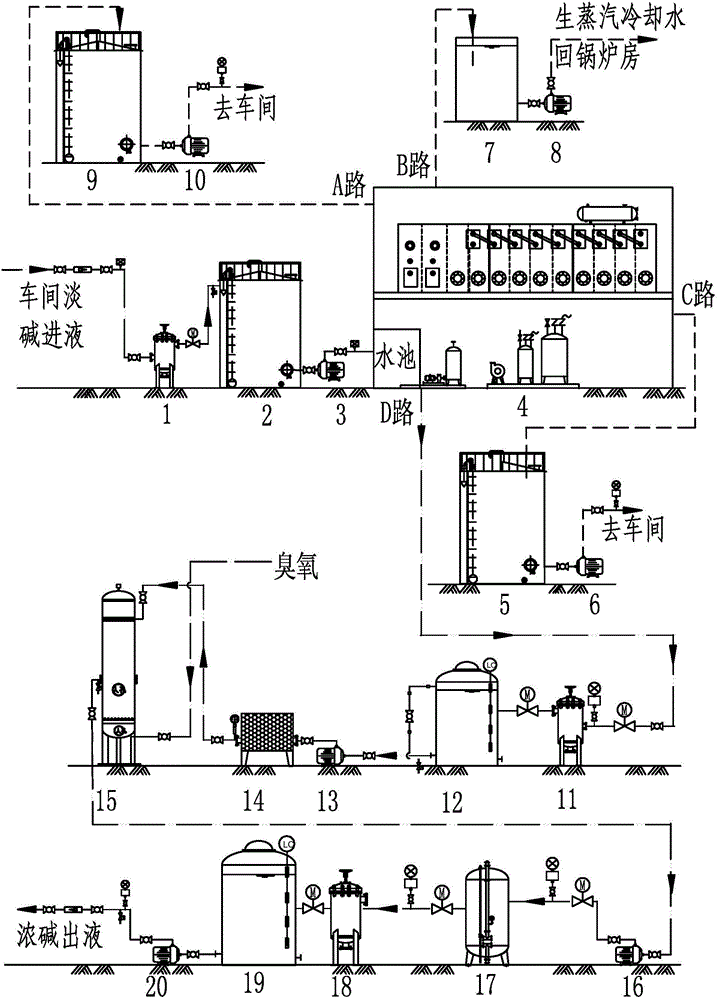

[0014] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] Such as figure 1 As shown, the present invention is a catalytic oxidation evaporation recovery system for yarn-dyed cloth mercerizing waste lye, including: weak lye filtration and collection unit, lye concentration evaporation and collection unit, and concentrated lye catalytic oxidation decolorization unit.

[0016] The light alkali liquor filtration and collection unit includes a self-cleaning filter A1, a light alkali collection tank 2 and a light alkali delivery pump 3 connected in series through pipelines; the light alkali collection tank 2 is provided with a thermometer and a liquid level gauge. Wherein the light alkali collecting tank 2 preferably comprises a plurality of tank bodies connected in series, and a thermometer and a liquid level gauge are respectively provided on each tank body.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com