A kind of surface modification method of carbon material

A technology of surface modification and carbon materials, which is applied in the field of carbon materials, can solve the problems of short stable storage time of carbon material solutions, high price of amphoteric surfactants, prolonging the storage time of carbon material solutions, etc., and achieve safety, environmental protection and large-scale production , good dispersion effect, good scale application prospect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

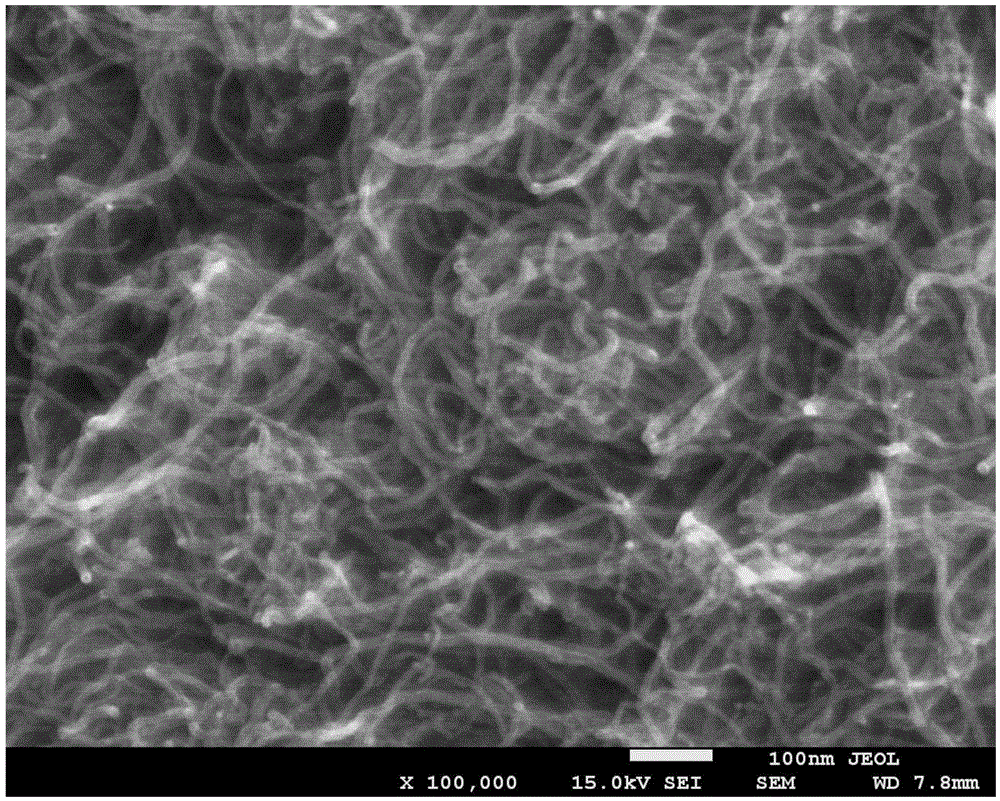

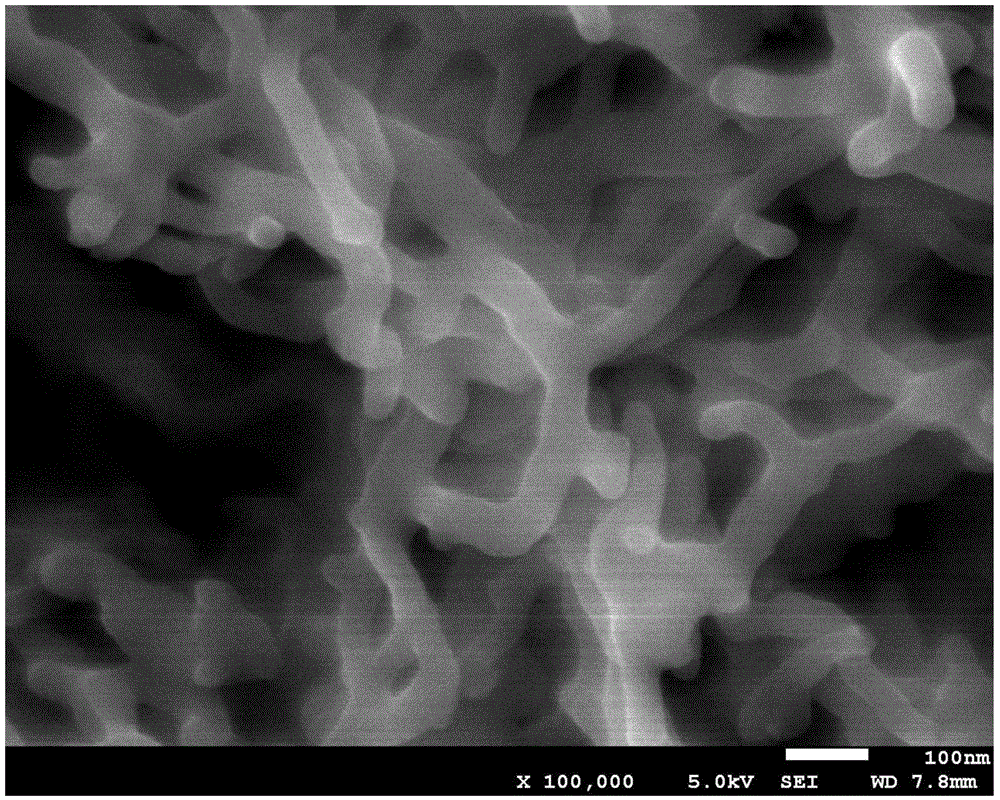

[0030] Mix 200 mg of unmodified carbon nanotubes and 200 mg of sucrose (the mass ratio of carbon nanotubes and sucrose is 1:1), then disperse the mixture in 40 mL of aqueous solution, and continue stirring until the sucrose is uniformly dissolved to obtain a solid-liquid mixture. Then transfer the solid-liquid mixture to a hydrothermal reaction kettle, and conduct a constant temperature hydrothermal reaction at 100°C for 24 hours. After the hydrothermal reaction is completed, naturally cool to obtain the modified carbon nanotube crude product, which is centrifuged at 10000rpm Centrifuge under the condition of rotating speed, collect the solid matter, and then wash with deionized water and absolute ethanol three times respectively to remove the residual reactants contained in the solid matter. After the washing is completed, dry the solid matter in an oven to obtain the improved Pure functionalized carbon nanotubes. Compared with untreated carbon nanotubes ( figure 1 ) and car...

Embodiment 2

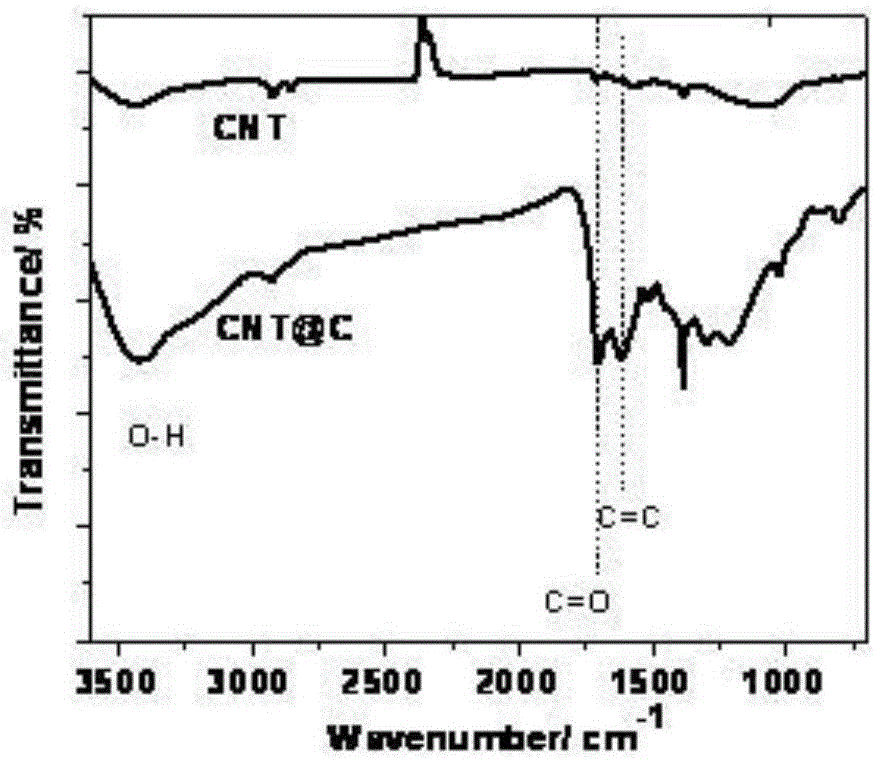

[0032] Mix 200 mg of unmodified carbon nanotubes and 2000 mg of sucrose (the mass ratio of carbon nanotubes and sucrose is 1:10), then disperse the mixture in 100 mL of aqueous solution, and continue stirring until the sucrose is uniformly dissolved to obtain a solid-liquid mixture. Then transfer the solid-liquid mixture to a hydrothermal reaction kettle, and conduct a constant temperature hydrothermal reaction at 120° C. for 18 hours. After the hydrothermal reaction is completed, naturally cool to obtain the modified carbon nanotube crude product, which is centrifuged at 9000 rpm Centrifuge under the condition of rotating speed, collect the solid matter, and then wash with deionized water and absolute ethanol three times respectively to remove the residual reactants contained in the solid matter. After the washing is completed, dry the solid matter in an oven to obtain the improved Pure functionalized carbon nanotubes. At the same time from Figure 4 It can be seen from the ...

Embodiment 3

[0034]Mix 200 mg of unmodified carbon nanotubes and 4000 mg of sucrose (the mass ratio of carbon nanotubes and sucrose is 1:20), then disperse the mixture in 40 mL of aqueous solution, and continue stirring until the sucrose is uniformly dissolved to obtain a solid-liquid mixture. Then transfer the solid-liquid mixture to a hydrothermal reaction kettle, and conduct a constant temperature hydrothermal reaction at 140°C for 12 hours. After the hydrothermal reaction is completed, naturally cool to obtain the modified carbon nanotube crude product, which is centrifuged at 5000rpm Centrifuge under the condition of rotating speed, collect the solid matter, and then wash with deionized water and absolute ethanol three times respectively to remove the residual reactants contained in the solid matter. After the washing is completed, dry the solid matter in an oven to obtain the improved Pure functionalized carbon nanotubes. At the same time from Figure 4 It can be seen from the infra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com