Lifting type round article transfer device

A technology of item transfer and lifting device, which is applied in the field of item transfer, can solve the problems of high equipment cost and cumbersome operation, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

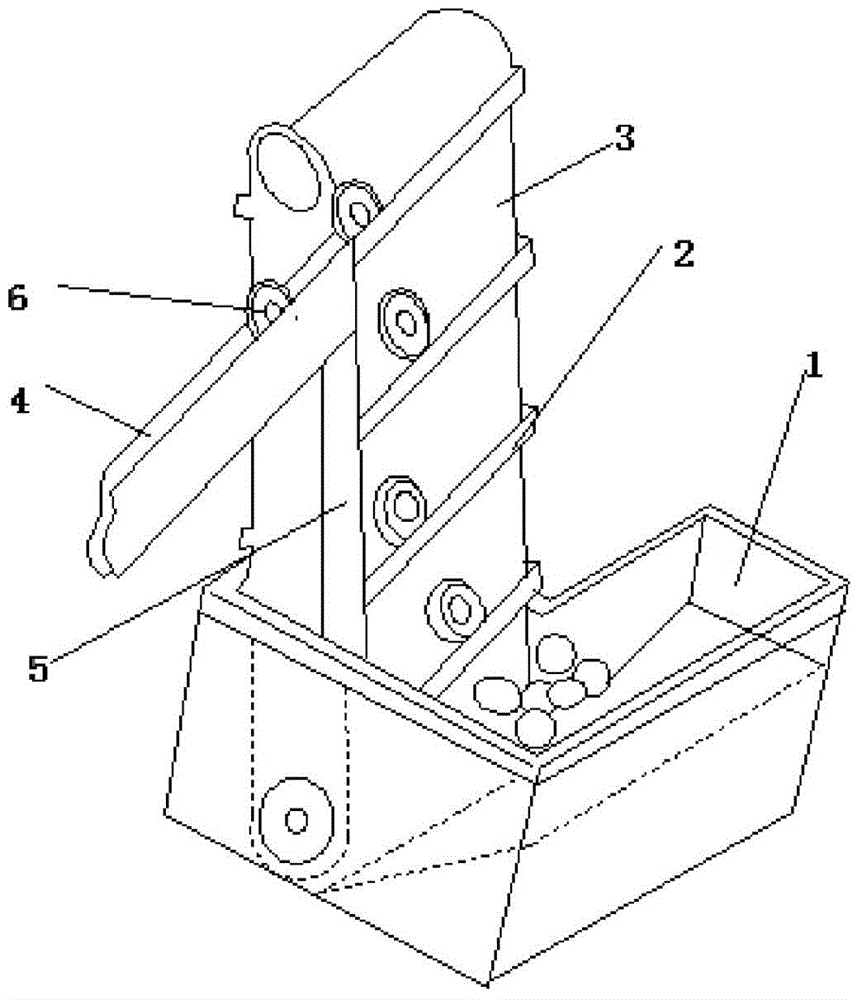

[0014] The reference signs in the description of the drawings are: material storage box 1, diversion flow groove 2, conveyor belt 3, conveying chute 4, baffle plate 5, round object 6.

[0015] Such as figure 1 As shown, the technical solution provides a lift-type circular article 6 transfer device, including a frame, a storage box 1, a lifting device and a transmission device. The interior of the storage box 1 is a tapered structure, which is convenient for round articles 6 quickly falls into the diversion flow cell 2. The lifting device is installed inside the material storage box 1, and the lifting device includes a conveyor belt 3, and the conveyor belt 3 is vertically arranged inside the material storage box 1. Conveyor belt 3 is fixedly installed with diversion channel 2 inclined downwards to the left, and the groove width of diversion channel 2 matches the width of round article 6, so that when round article 6 falls into diversion channel 2, the The circumferential sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com