Local secondary screen bulkhead applied to B type independent cabin and boat or ocean structure

A local and sub-screen technology, which is applied in the direction of bulk goods, can solve the problems of complex structure of the screen wall system and high installation process requirements, and achieve obvious economic benefits, reduce production costs, and low requirements for hardware equipment and construction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

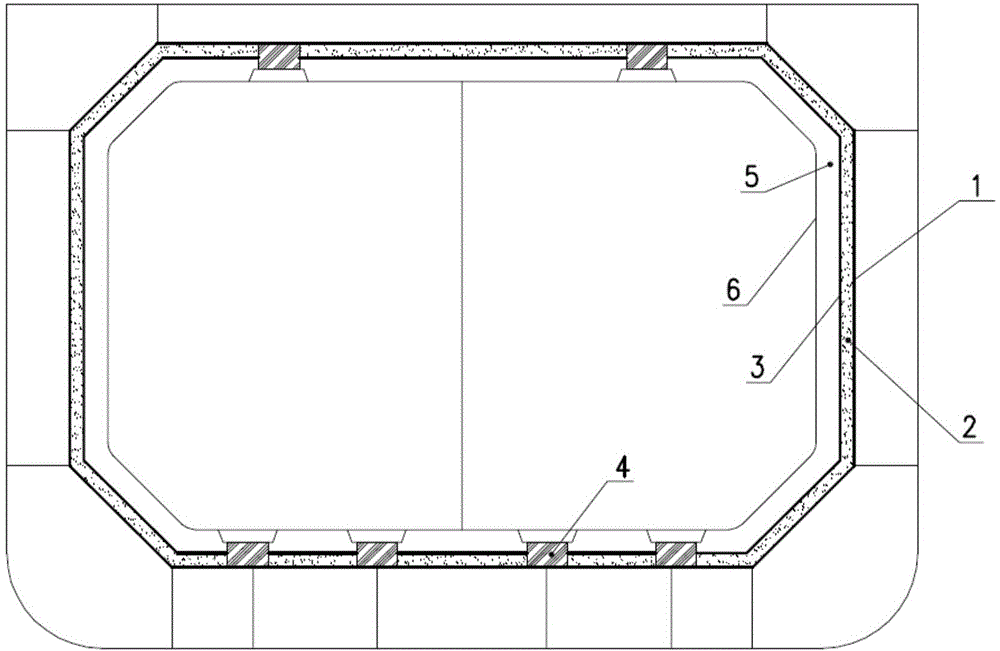

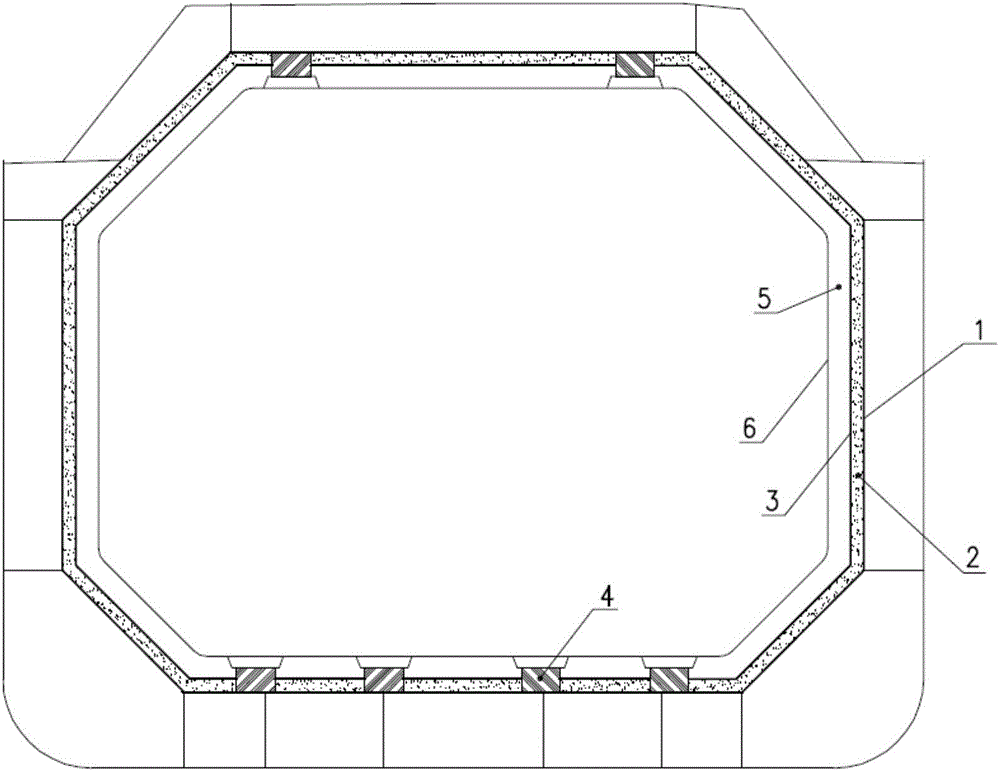

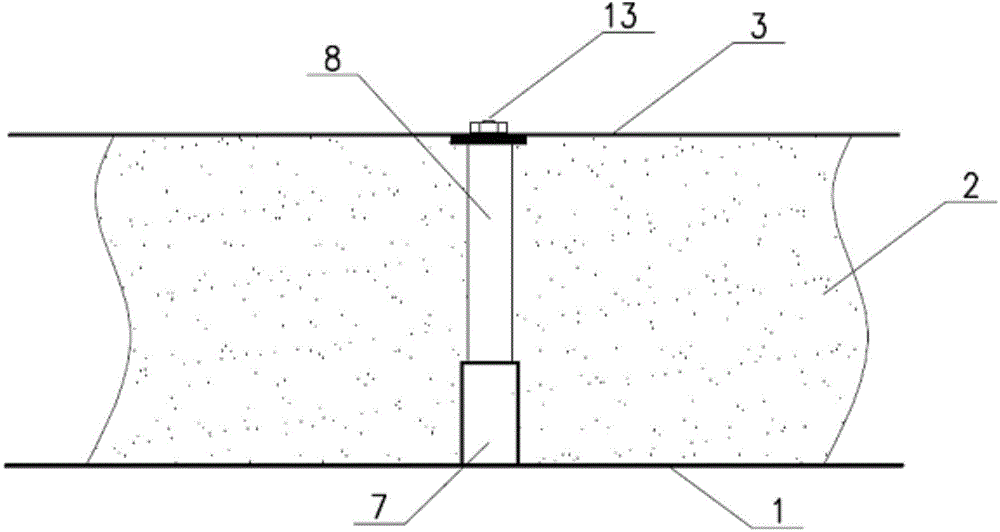

[0030] In order to further explain the technical means adopted by the present invention to achieve the intended purpose of the invention, the specific implementation of the partial secondary barrier system for B-type independent liquid cargo tank proposed according to the present invention, Structure, characteristic and effect thereof are as follows in detail. However, to the extent the following description is specific to a particular embodiment or a particular use of the invention, it is intended for purposes of illustration only and simply provides a description of the exemplary embodiments. Accordingly, the invention is not limited to the specific embodiments described below, but includes all alternative modifications and equivalents falling within the true spirit and scope of the appended claims.

[0031] The embodiment of the present invention is applied to the Type B independent cargo tank storage tank described in the IGC code. More specifically, the storage tank can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com