Tread brake

A tread brake and screw technology, which is applied in the field of rail vehicle braking systems, can solve problems such as actuator jamming and reducing the reliability of tread brakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

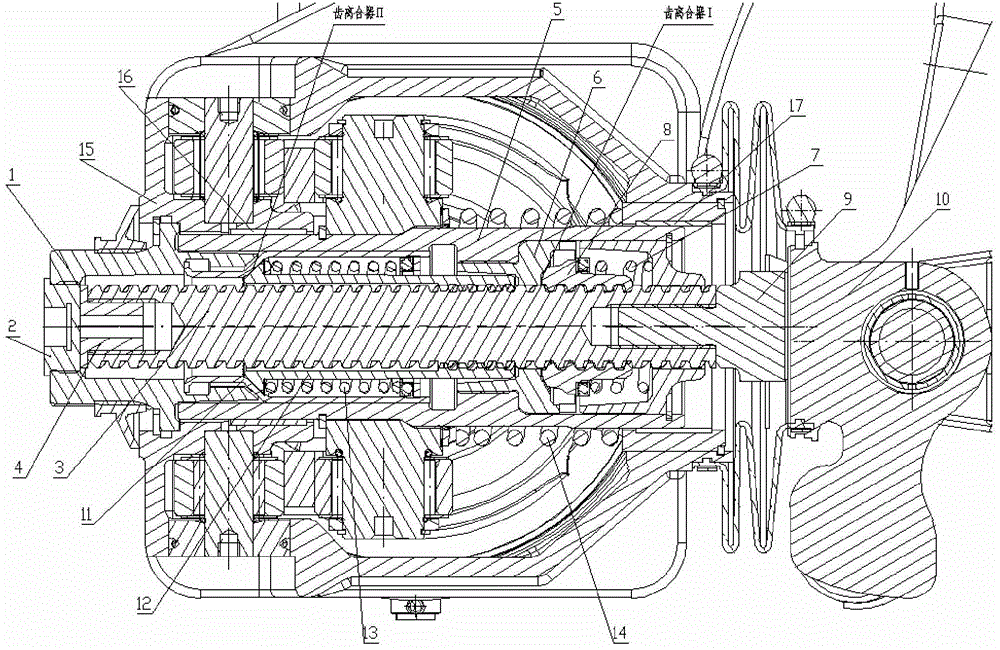

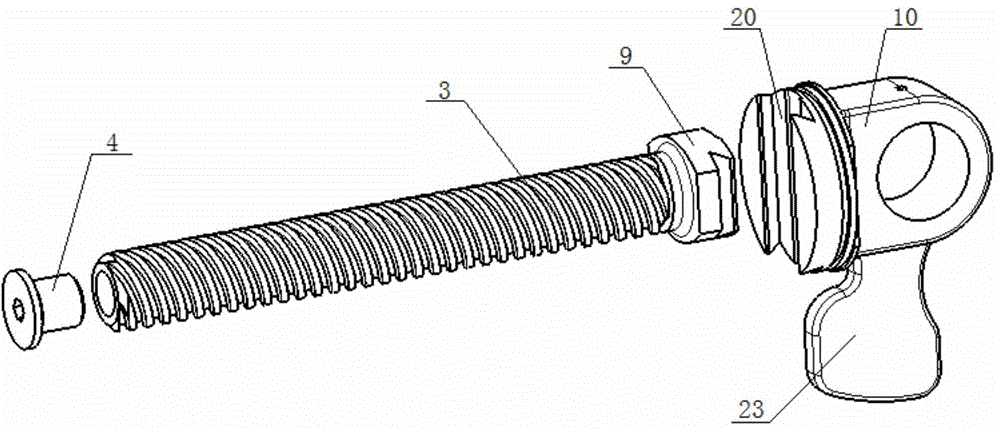

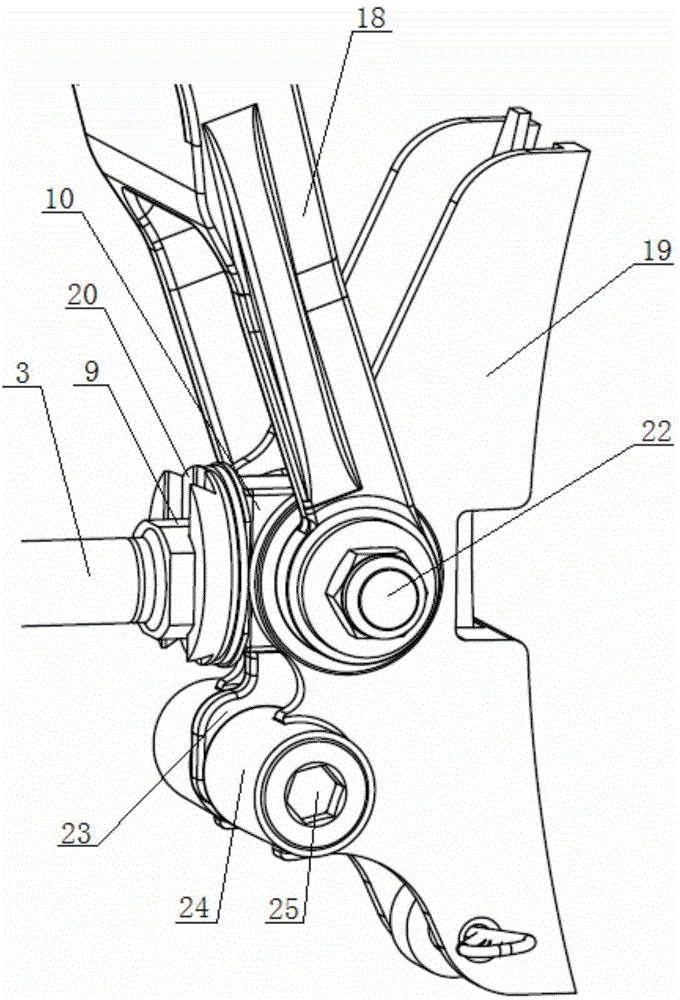

[0027] Such as Figures 1 to 4 As shown, the tread brake of this embodiment comprises a box body 15, a brake adjustment sleeve 5 which is supported in the box body 15 by the front sliding bushing 17 and the rear sliding bushing 16 and can slide back and forth, and is arranged in the sleeve. The screw mandrel 3, the feed nut 8 and the adjustment nut 12 threaded on the screw mandrel 3, the screw mandrel head 9 connected to the front end of the screw mandrel 3, the brake shoe support 19 driven by the screw mandrel head 9, the brake adjusting sleeve 5 An adjustment seat 6 is fixed inside, and an adjustment sleeve 11 is connected through a guide key. The teeth betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com