Automobile power assembly suspension structure

An automobile powertrain and powertrain technology, applied in the direction of power units, vehicle components, jet propulsion devices, etc., can solve problems such as damage to the suspension structure, poor cushioning effect, poor powertrain limit effect, etc., to achieve Guaranteed connection stiffness, good shock absorption effect, and reliable transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

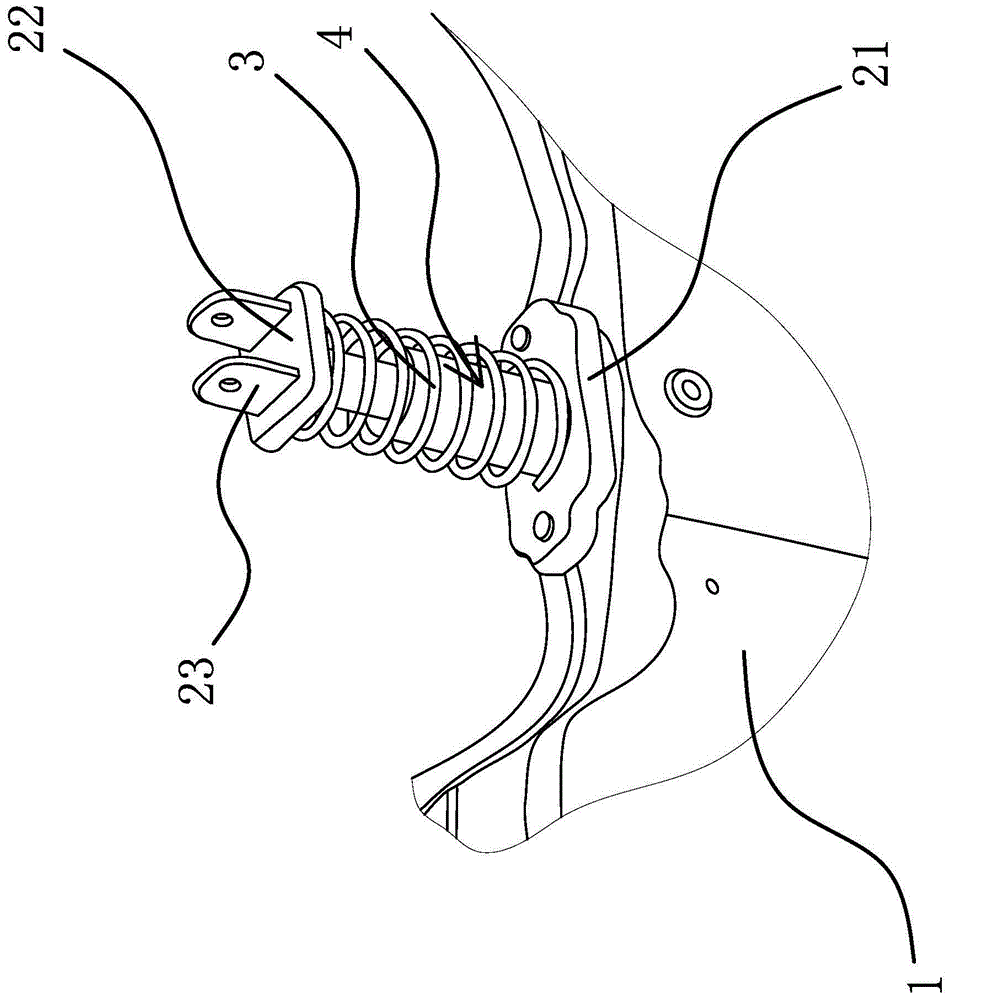

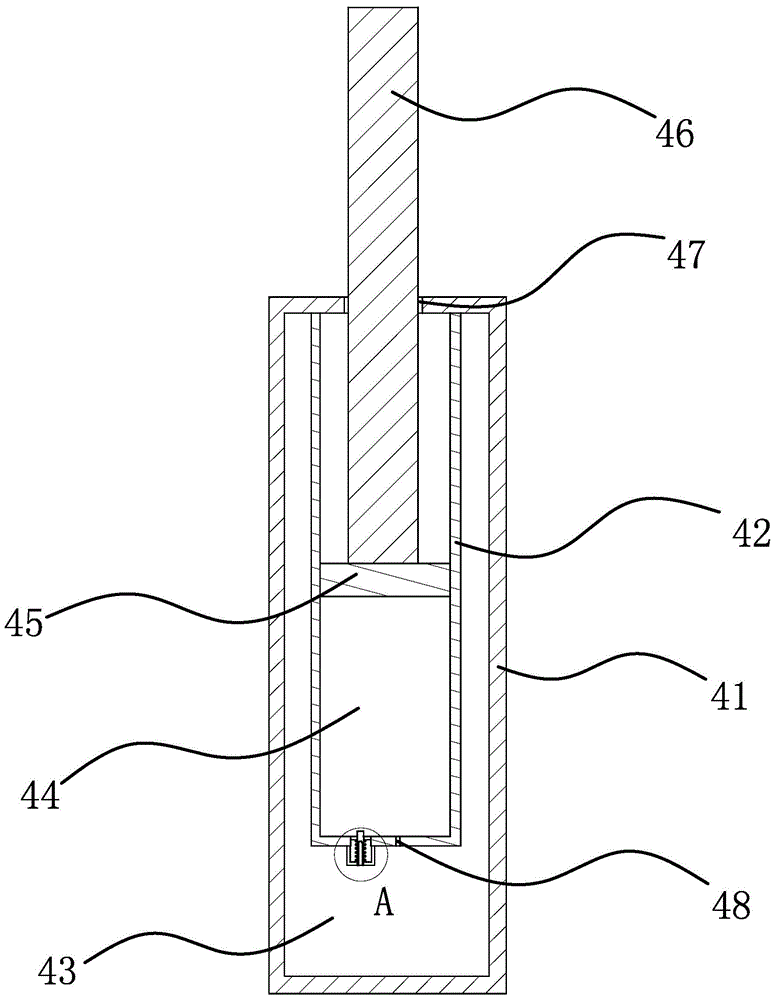

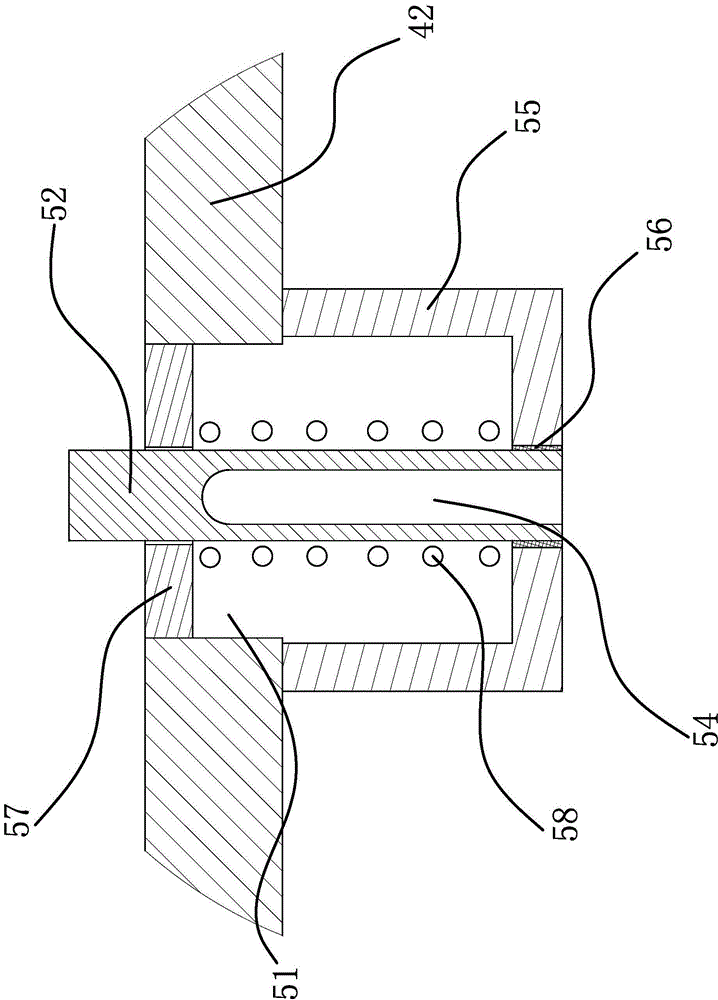

[0023] Such as figure 1 As shown, an automobile powertrain suspension structure. The automobile includes a powertrain and a subframe assembly 1. The suspension structure includes a mounting support 21 fixedly connected to the subframe assembly 1 and a powertrain assembly There is also a spiral damping spring 3 between the two fixed mounting supports 22, the one 21 and the two 22 mounting supports, and the suspension structure also includes a fixed connection to the one 21 and mounting The limiting member 4 between the two supports 22 is placed in the spiral through hole of the shock-absorbing spring 3 and only allows the power assembly to move along the axis of the shock-absorbing spring 3. A plurality of the above-mentioned suspension structures support the power assembly at multiple points, and a spiral damping spring 3 is used to connect between the mounting support 21 and the mounting support 22, in the spiral through hole of the damping spring 3. A limit piece 4 is provide...

Embodiment 2

[0027] The content of this embodiment is roughly the same as that of the first embodiment. The difference is: the cavity one 43 and the cavity two 44 are filled with hydraulic oil. The principle of this solution is the same as that of the above solution. The advantage in comparison is that The hydraulic oil fills the first cavity 43 and the second cavity 44, which makes it easier to seal the piston 45 and the cylinder 42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com