Roller coder for coding workpieces by using extrusion principle and method of use thereof

A rolling code machine and workpiece technology, which is applied in the field of rolling code machines, can solve problems such as hidden safety hazards, low efficiency, and many defective products, and achieve the effects of high safety, simple operation, convenient and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

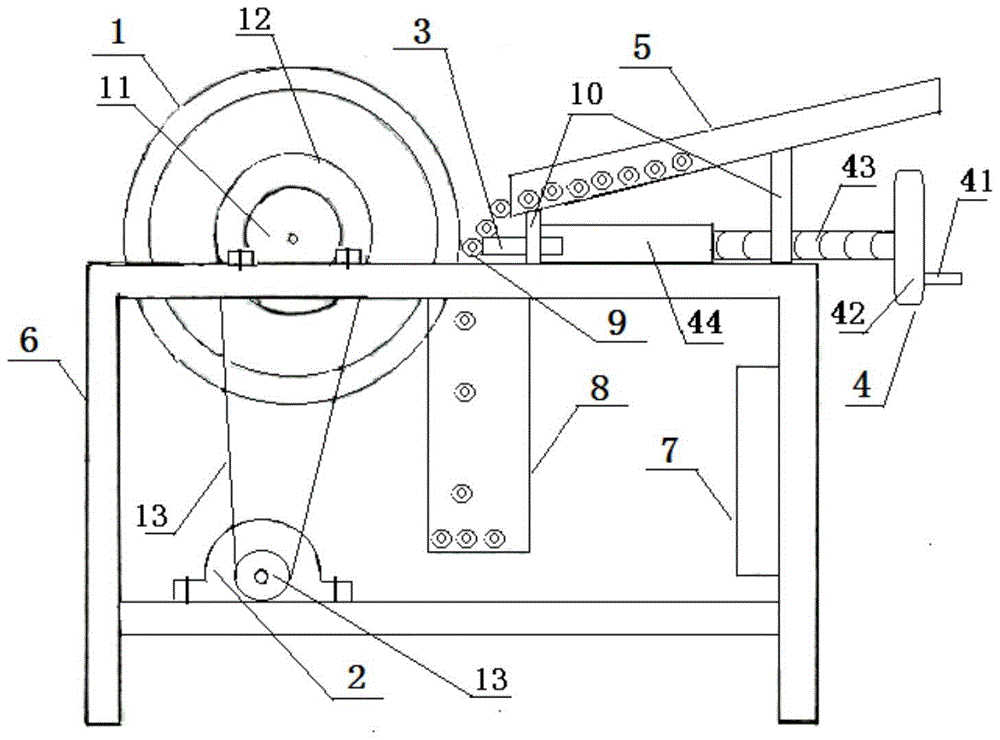

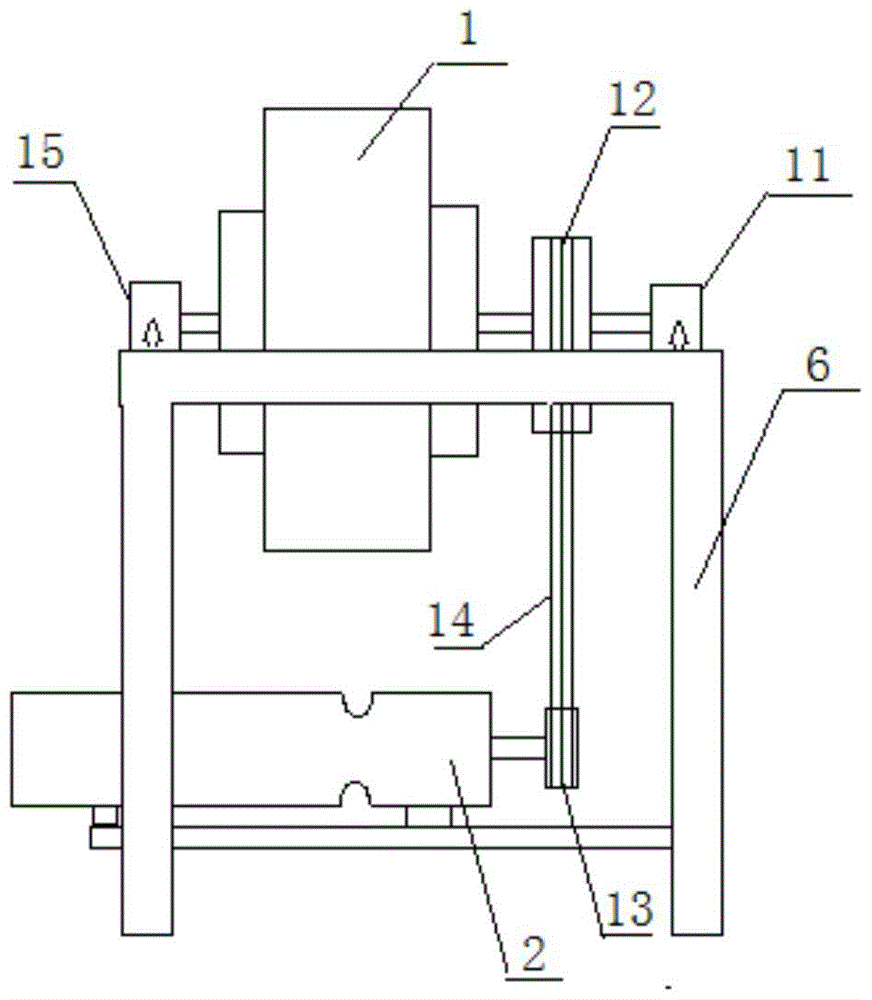

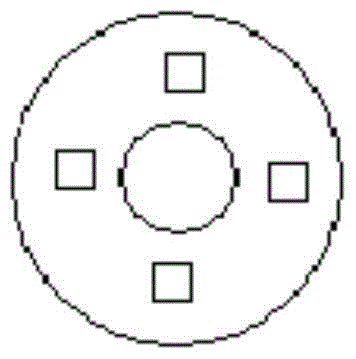

[0035] Such as figure 1 As shown, a rolling code machine of this embodiment that utilizes the principle of extrusion to code workpieces includes a reducer 2, a feed trough 5, a frame-shaped support 6, an electric box 7 and a discharge port 8, and also includes an inertial Flywheel 1, steel code 3 and extrusion adjustment mechanism 4; the front end of the reducer 2 is provided with a lower pulley 13; the front end of the inertial flywheel 1 is provided with an upper pulley 12; the reducer 2 is fixedly installed on The left part of the lower crossbeam of the frame support 6; as figure 2 As shown, the centers of circles of the inertial flywheel 1 and the upper pulley 12 are on the same axis, the two are connected by a rotating shaft, and are fixed in the bearings A11 and B15 respectively arranged on the front and rear two upper beams of the frame support 6, the bearings A11 and bearing B15 are fixed on the front and rear two upper beam upper surfaces of the frame-shaped support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com