Anti-rotation tool for chain wheel

A sprocket and anti-rotation technology, used in workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of not designing anti-rotation structures and affecting installation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below through specific implementation examples in conjunction with the accompanying drawings.

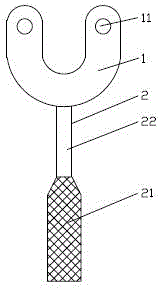

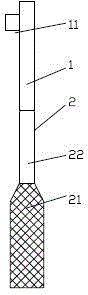

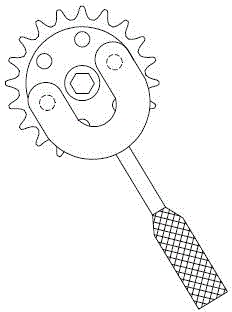

[0011] figure 1 , figure 2 , image 3 The sprocket anti-rotation tool provided by the present invention is shown, including a U-shaped tooling plate 1. Two straight arms of the U-shaped tooling plate 1 are respectively provided with positioning pins 11 matching the process holes of the sprocket; U-shaped tooling plate 1 The distance between the two straight arms of the sprocket is greater than the maximum size of the head of the mounting bolt in the center hole of the sprocket; the closed end of the U-shaped tooling plate 1 is welded with a cylindrical handle 2. The handle is divided into a hand-held knurled section 21 and a smooth section 22. The smooth section 22 is connected with the U-shaped tooling plate 1. Both the U-shaped tooling plate 1 and the handle 2 are steel parts.

[0012] The foregoing descriptions are on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com