Scraping system for grinding wheel production

A scraping and grinding wheel technology, used in metal processing equipment, grinding devices, grinding/polishing equipment, etc., to achieve the effect of improving uniformity and flatness, improving flatness accuracy, and improving use safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

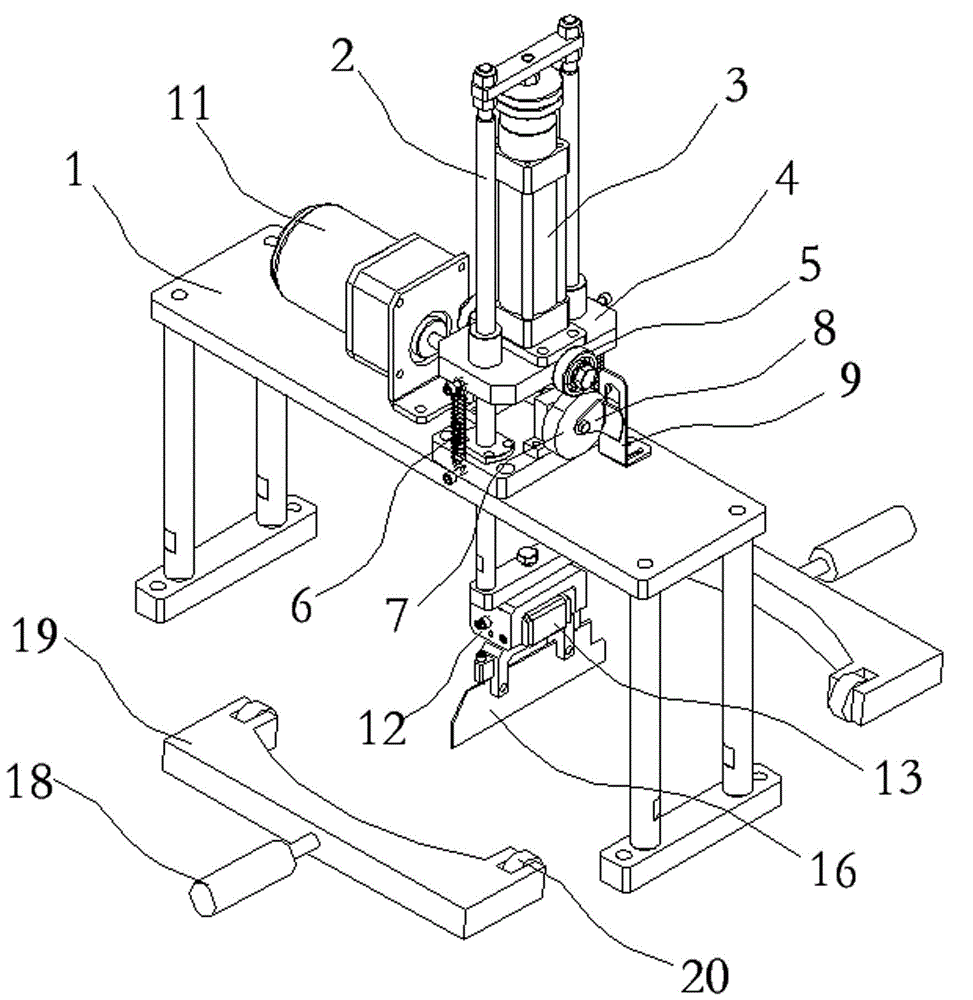

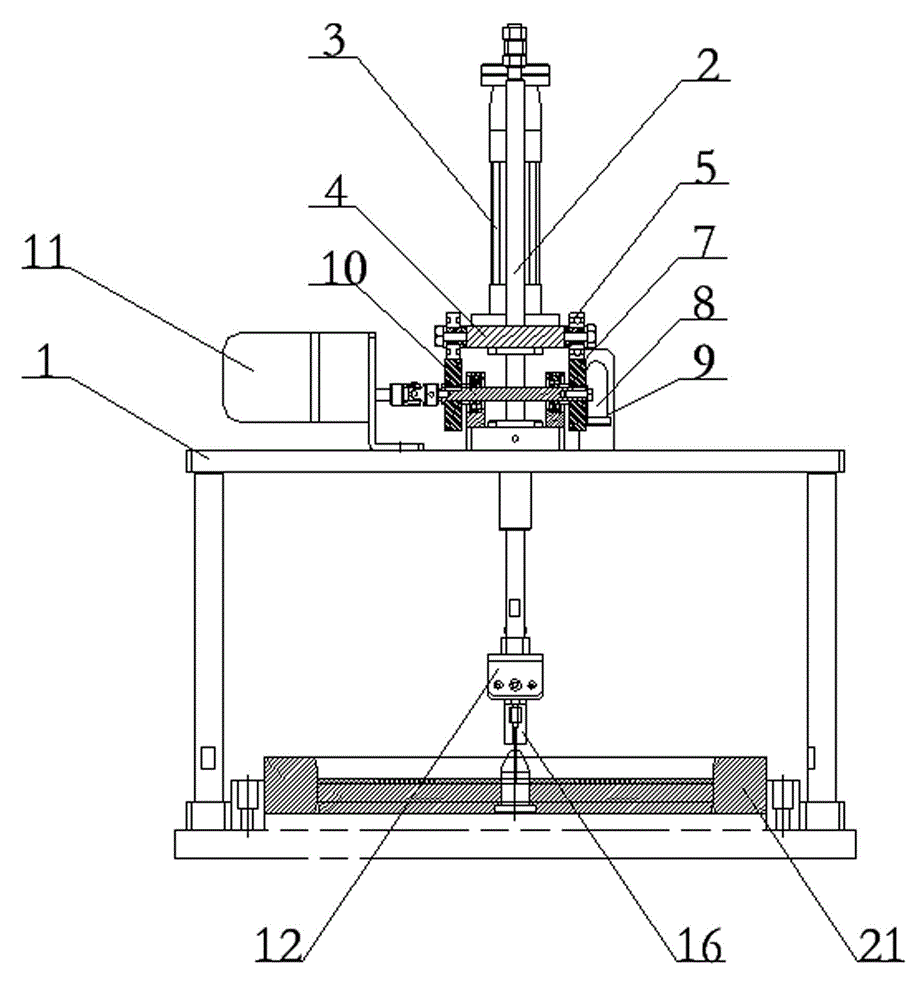

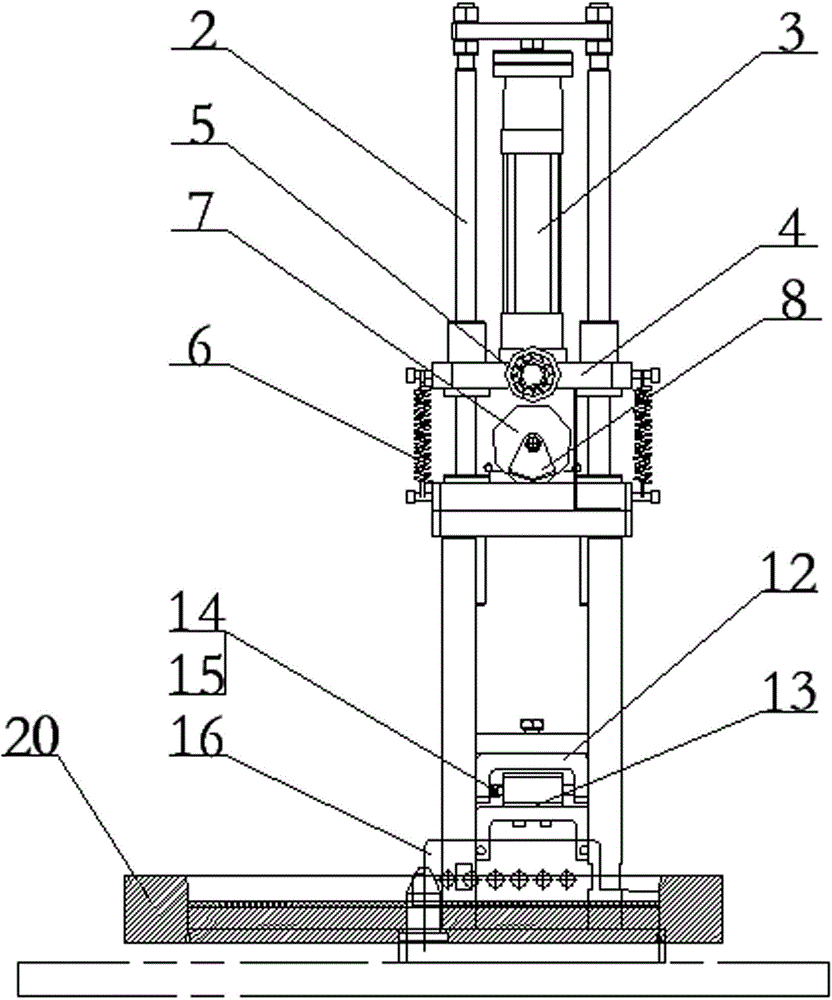

[0020] Figure 1-4 As shown, a scraping system for grinding wheel production includes a scraper bracket 1, a lift rod 2, a lift cylinder 3, a cylinder support plate 4, a support wheel 5, a support spring 6, a fine-tuning eccentric wheel 7, a fine-tuning sensor head 8, and a fine-tuning sensor 9. Fine-tuning shaft 10, fine-tuning motor 11, scraper holder 12, scraper adjustment seat 13, connecting shaft 14, spring 15, scraper 16, positioning cylinder 18, positioning bayonet 19 and roller 20. A grinding wheel forming mold 21 is supported on the grinding wheel forming machine, and the grinding wheel forming mold 21 is in a passive rotation state. Positioning bayonets 19 are arranged on both sides of the non-feeding direction of the grinding wheel forming mold 21, and the inside of the positioning bayonet 19 corresponds to the circumference of the grinding wheel forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com