Novel welding equipment

A welding equipment, a new type of technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of heavy equipment workload, low stability, high energy consumption, etc., to improve welding stability, increase adjustment methods, The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

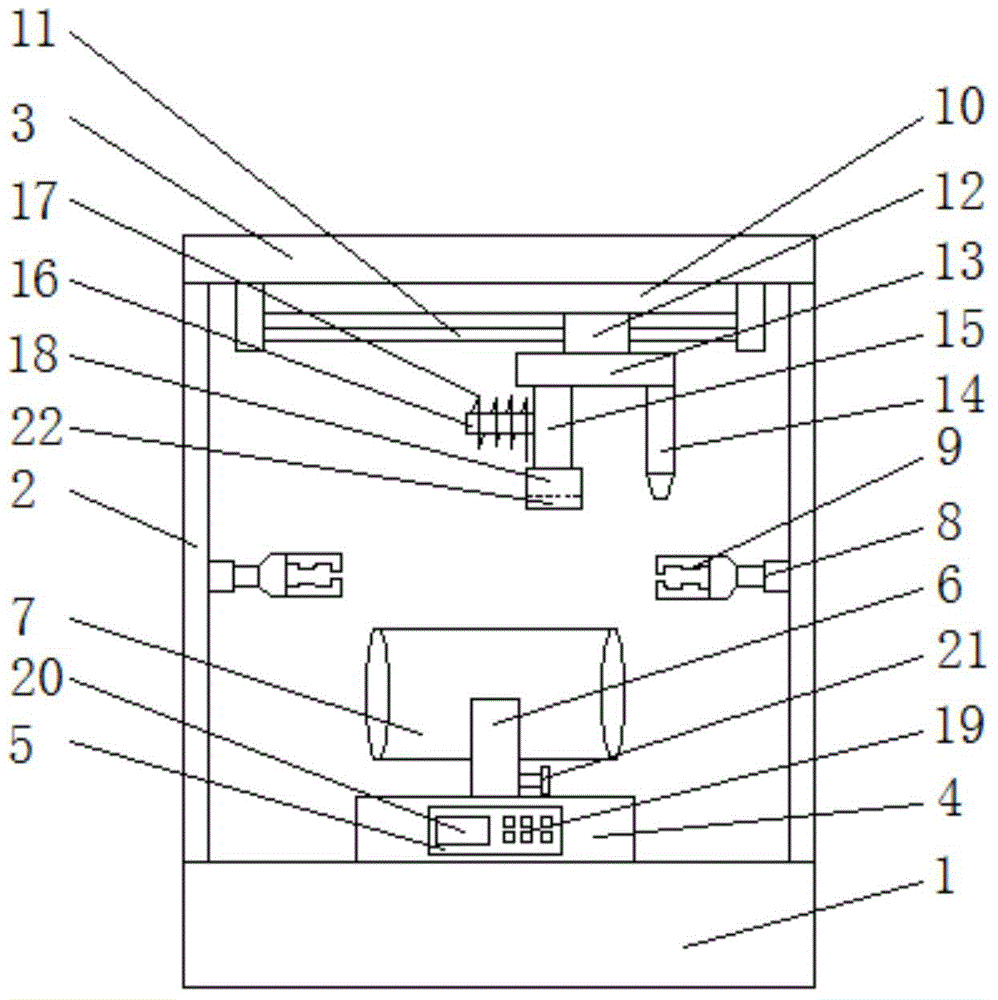

[0021] Such as figure 1 As shown, this embodiment includes an operating table 1, a column 2, a top plate 3, a lifting platform 4, an operating area 5, a clamping groove 6, a tank body 7, a telescopic rod 8, a clamp 9, an electric cylinder 10, a guide rail 11, an electric slide Block 12, connecting plate 13, welding torch 14, connecting rod 15, rotating shaft 16, welding wire 17 and briquetting block 18, the four corners of console 1 are respectively fixed with column 2 lower ends, and column 2 upper ends are fixed on top plate 3 corresponding positions, The middle part of the console 1 is equipped with a lifting platform 4, and the front side of the lifting platform 4 is provided with an operation area 5. The operating area 5 includes a keyboard 19 and a display screen 20. The lifting platform 4 on the upper side of the keyboard 19 is provided with a display screen 20, and the lifting platform 4 The middle part of the upper side is fixed with a clamping groove 6, and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com