High-speed disk type separator

A sorter and disc technology, applied in centrifuges and centrifuges with rotary drums, etc., can solve the problems of poor desliming effect of the desliming bucket, and achieve high desliming efficiency and low metal water loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

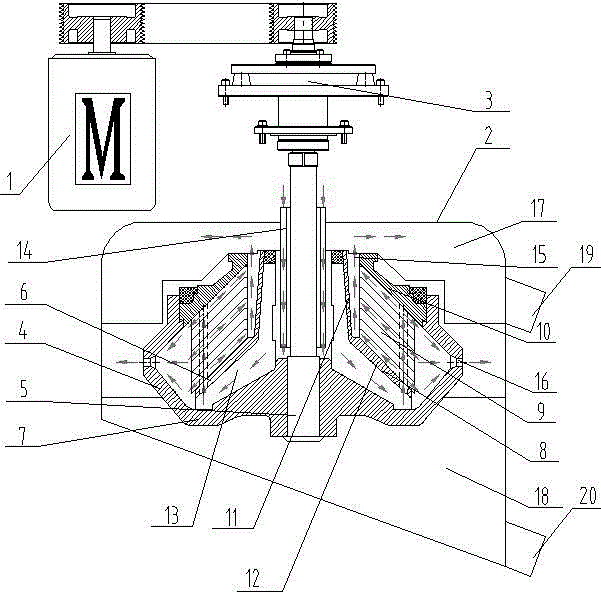

[0013] Such as figure 1 As shown, the present invention includes a motor 1 , a drum casing 2 , a transmission device 3 and a drum assembly 4 .

[0014] The drum assembly 4 is placed in the drum casing 2. The drum assembly 4 includes a main shaft 5, a working disk assembly 6 and a drum 7. The main shaft 5 is vertically placed at the vertical center of the drum 7. The main shaft 5 and the drum 7 The lower end of the drum 7 is sealed and fixedly connected, the upper end of the drum 7 is open, and the working disc assembly 6 is installed in the drum 7; the motor 1 is connected with the main shaft 5 through the transmission device 3 .

[0015] The work disk assembly 6 includes a work disk support 8, a work disk gland 10 and several frustum-shaped work disks 9. The work disk support 8 includes an upper connection section 11 and a lower conical section 12. The work disk support 8 is set in the drum 7 , the inner wall of the work disk support 8 is provided with support ribs 13, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com