Filter backwashing method and filter

A filter and backwashing technology, applied in gravity filters, chemical instruments and methods, loose filter material filters, etc., can solve problems such as low backwashing efficiency, save energy, reduce water washing intensity, improve The effect of interception capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

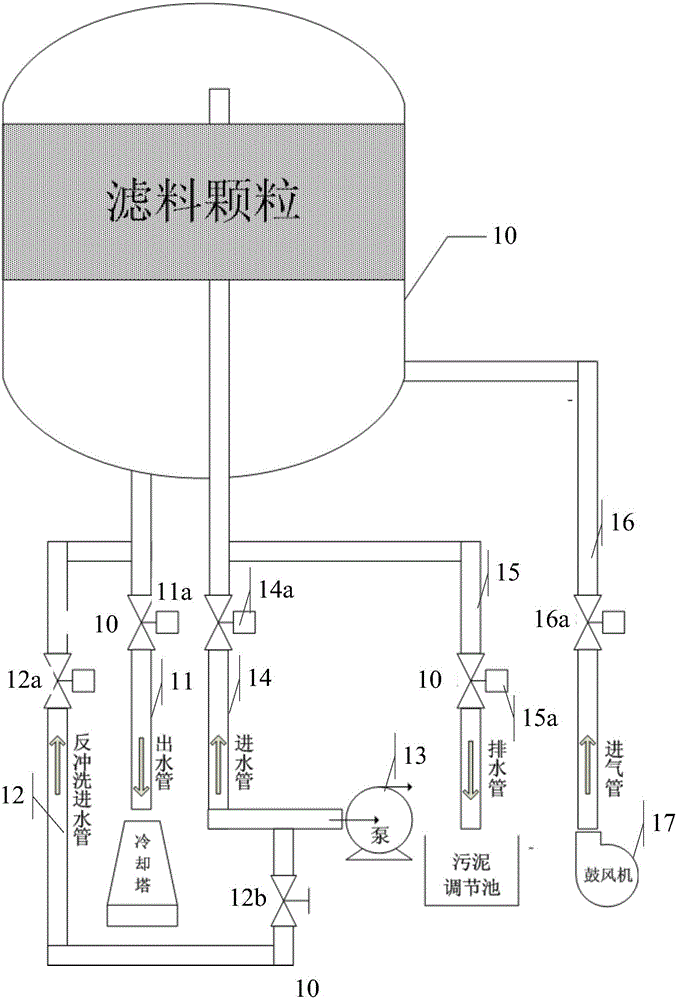

[0123] In this embodiment, the backwashing method is introduced by applying the method to a quartz sand filter, and the quartz sand filter has a structure such as figure 1 As shown, wherein, after the drain valve 15a is opened, the water in the filter is discharged into the sludge adjustment tank; the water inlet valve 14a is opened to allow the water from the suction pump to enter the top of the filter layer, and the filter filters it; The water outlet valve 11a is opened and the water filtered by the filter flows into the cooling tower for cooling, which is used to provide water for rolling steel; Water backwashing is carried out at the bottom of the filter layer; after the air washing valve 16a is opened, the blower 17 is used to blow compressed air into the bottom of the filter layer for air backwashing.

[0124] Please refer to Figure 5 , the backwashing method in the present embodiment comprises the following steps:

[0125] Step S501: When the measured flow value of ...

Embodiment 2

[0135] In this example, this method is applied to figure 1 The quartz sand filter shown is taken as an example to introduce the monitoring process of each component of the quartz sand filter during the implementation of the method.

[0136] Please refer to Image 6 , the monitoring process includes the following steps:

[0137] Step S601: Detect whether there is a need for backwashing, if the result is yes, go to step S602; if the result is no, go to step S601a;

[0138] Step S602: Check whether it is ready, if the result is yes, then jump to step S603;

[0139] Step S603: Judging whether it is manual, if the judging result is yes, go to step S603a; if judging structure is no, go to step S604;

[0140] Step S603a: perform manual backwashing, and jump to step S603b;

[0141] Step S603b: Determine that automatic backwashing is not completed;

[0142] Step S604: Judging whether to stop automatic hand washing, if the judgment result is yes, go to step S604a; if the judgment r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com