Distillation tower

A technology of distillation tower and tower body, applied in the field of distillation tower, can solve the problems of unsatisfactory structure of distillation tower, increase of production cost, failure to achieve distillation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

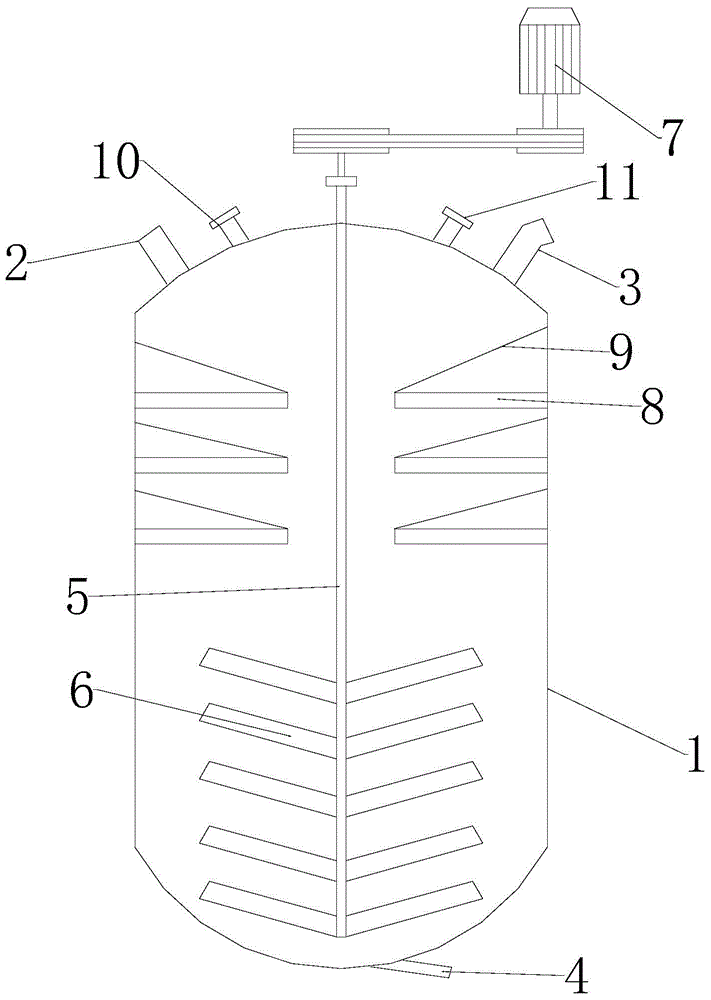

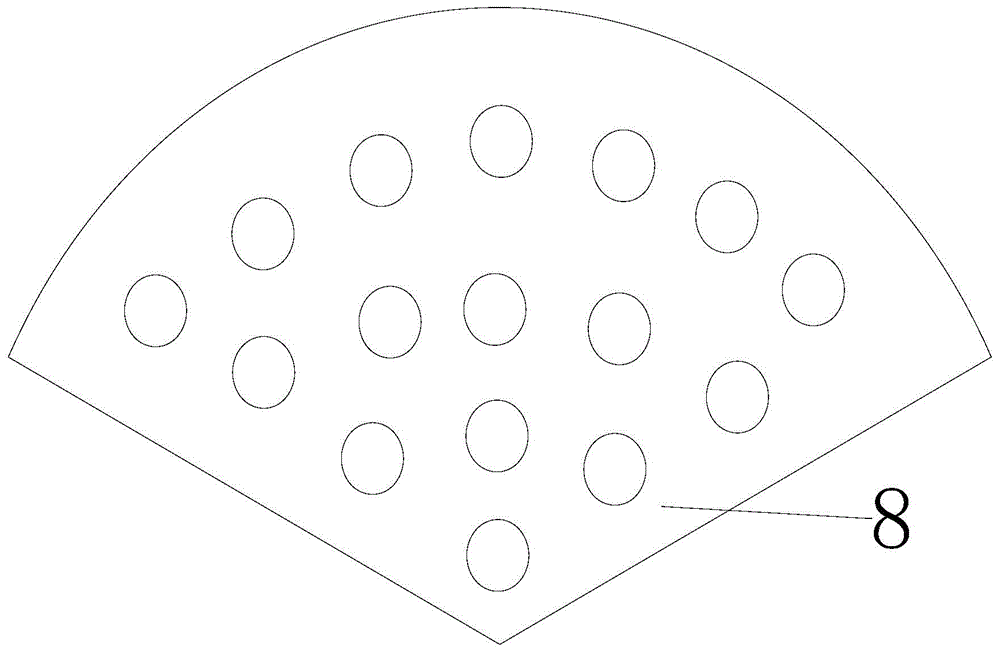

[0013] Depend on figure 1 and figure 2 It can be seen that a distillation tower of the present invention comprises a tower body 1, a feed inlet 2 and an air outlet 3 are arranged on the upper part of the tower body 1, a discharge outlet 4 is arranged on the lower part of the tower body, a stirring shaft 5 is arranged in the tower body 1, The stirring shaft 5 is provided with a plurality of electric heating rods 6, the stirring shaft 5 extends upwards and extends out of the tower body 1, the upper end of the stirring shaft 5 is connected to the drive motor 7 by transmission, and the tower body 1 is provided with A plurality of baffles 8, one end of the baffle 8 is hinged to the inner wall of the tower body, and the other end is connected to the inner wall of the tower body 1 through a positioning rope 9, and a plurality of small holes are arranged on the baffle plate 8, and on the tower body 1 A temperature measuring device 10 and an air pressure measuring device 11 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com