Take-in type endoscopic surgery net bag suture needle

A suture needle and a technique for surgery, which are applied in the field of bring-in endoscopic surgery mesh pocket suture needles, can solve the problems of inconvenient removal and insertion of the suture needle, difficult suture operation under endoscopic operation, and easily damaged tissues or organs, and the like. Good corrosion resistance, excellent mechanical properties, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

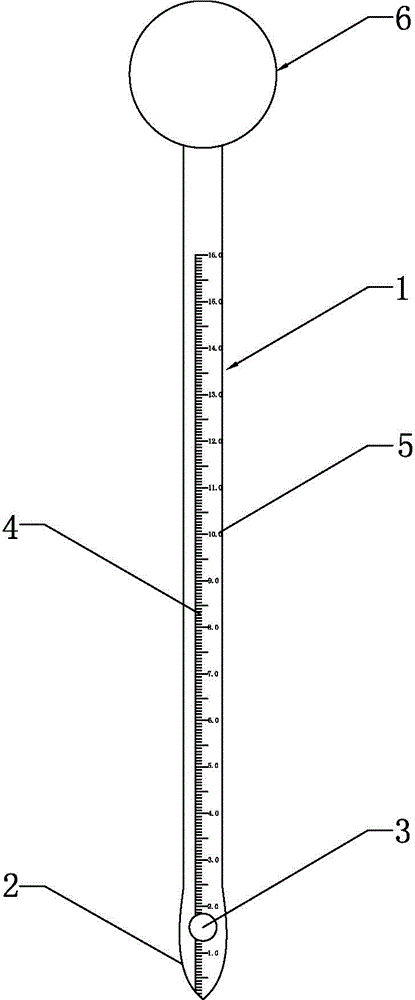

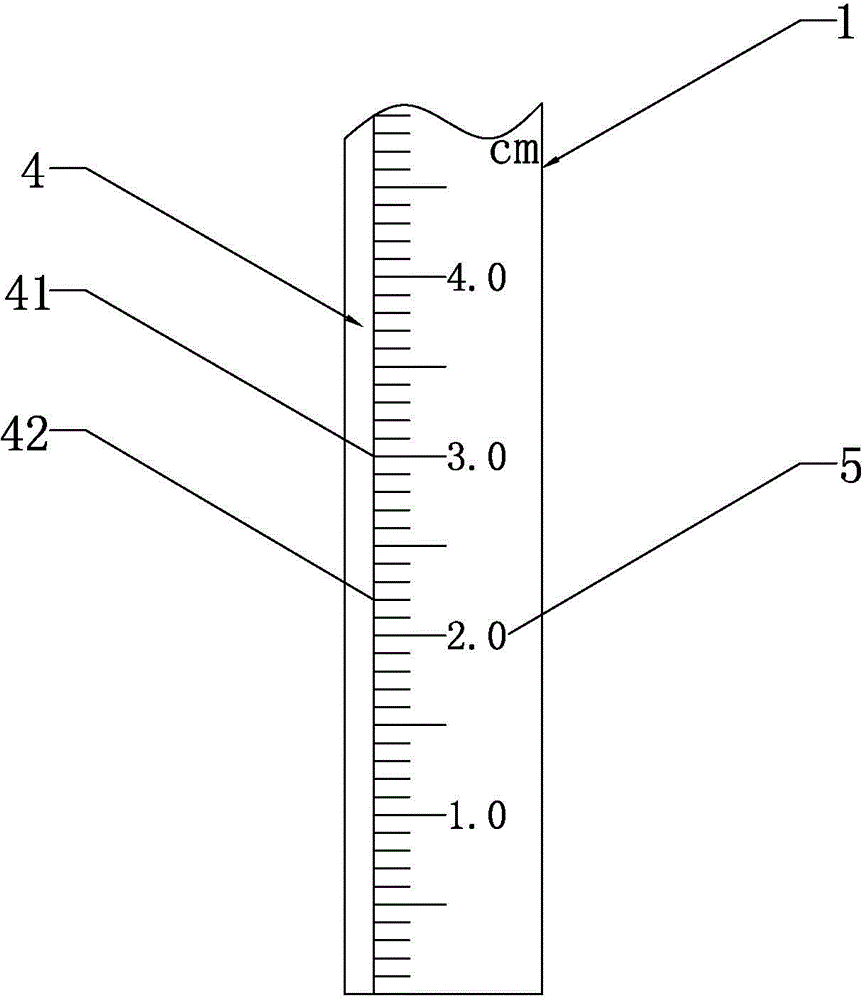

[0029] See Figure 1-2 , a kind of net bag suturing needle that brings into endoscopic operation, comprises needle body 1, the needle head 2 that is arranged on the front end of needle body 1, and the needle hole 3 that is opened in needle head 2, and the outer wall of described needle body 1 is provided with scale 4 And scale value 5, scale 4 comprises long scale 41 and short scale 42, is provided with four short scales 42 between adjacent two long scales 41, and the distance between adjacent two long scales 41 is 0.5cm, adjacent The distance between the two short scales 42 is 0.1 cm, the scale value 5 is set on one side of the long scale 41 , and a scale value 5 is set every two long scales 41 from the front end of the needle body 1 .

[0030] In this embodiment, the length of the needle body 1 is 15 cm, the diameter is 1 mm, the length of the scale 4 is 120 cm; the length of the needle head 2 is 3 mm, and the diameter of the pinhole 3 is 0.6 mm.

[0031] In this embodiment...

Embodiment 2

[0049] The difference between this embodiment and the above-mentioned embodiment 1 is: the length of the needle body 1 is 18cm, the diameter is 1.1mm, the length of the scale 4 is 14cm; the length of the needle head 2 is 4mm, the needle The diameter of hole 3 is 0.8mm.

[0050] The needle body 1 is made of medical stainless steel material, and the medical stainless steel material includes the following chemical elements in weight percentage: C: 0.12%, Si: 0.7%, Mn: 8%, Al: 0.2%, Cr: 15%, Ni: 2%, N: 0.7%, Mo: 2.8%, Cu: 1.1%, Ti: 0.2%, Zr: 0.02%, Re: 0.02%, P≤0.008%, S≤0.008%, and the balance is Fe.

[0051] The preparation method of the needle body 1 comprises the following steps:

[0052] (1) Melting: Nitrogen protection, refining at 1412°C according to the above chemical composition ratio, nitrogen pressure maintained at 0.32MPa, pouring temperature at 1405°C to obtain a vacuum ingot, and then electroslag remelting with inert gas protection to obtain surface quality Smoothe...

Embodiment 3

[0061] The difference between this embodiment and the above-mentioned embodiment 1 is: the length of the needle body 1 is 20cm, the diameter is 1.2mm, the length of the scale 4 is 16cm; the length of the needle head 2 is 4mm, the needle The hole 3 has a diameter of 1 mm.

[0062] The needle body 1 is made of medical stainless steel material, and the medical stainless steel material includes the following chemical elements in weight percentage: C: 0.15%, Si: 0.8%, Mn: 9%, Al: 0.3%, Cr: 16%, Ni: 3%, N: 0.8%, Mo: 3%, Cu: 1.2%, Ti: 0.3%, Zr: 0.03%, Re: 0.03%, P≤0.005%, S≤0.005%, and the balance is Fe.

[0063] The preparation method of the needle body 1 comprises the following steps:

[0064] (1) Melting: nitrogen protection, refining at 1475°C according to the above chemical composition ratio, nitrogen pressure maintained at 0.35MPa, pouring temperature at 1410°C to obtain vacuum ingots, and then electroslag remelting with inert gas protection to obtain surface quality Smoother...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com