A kind of kiwi pollen mixture and its preparation method and application

A technology of pollen mixture and kiwifruit, which is applied in the direction of botanical equipment and methods, application, plant genetic improvement, etc., to achieve the effects of reducing costs, promoting germination, increasing fruit setting rate and single fruit weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

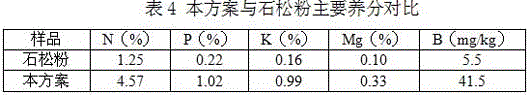

[0021] Dry the filaments, petals and calyxes of kiwifruit male flowers at 40°C for 20 hours respectively; pass the dried filaments, petals and calyxes through a 200-mesh sieve; collect the sieved powder to obtain filament powder and petal powder respectively and calyx powder; after mixing 6 parts of silk powder, 3 parts of petal powder, 8 parts of calyx powder and 1 part of kiwi male flower pollen, the kiwi pollen mixture was prepared and stored at 0°C. The main nutrients in the additives (filament powder, petal powder and calyx powder) in the kiwifruit pollen mixture except male flower pollen are shown in Table 1, and Lycopodium powder was used as the control group.

[0022]

Embodiment 2

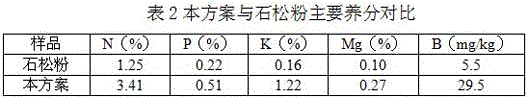

[0024] Dry the filaments, petals and calyxes of kiwifruit male flowers at 70°C for 13 hours respectively; pass the dried filaments, petals and calyxes through a 200-mesh sieve; collect the sieved powder to obtain filament powder and petal powder respectively and calyx powder; after mixing 8 parts of silk powder, 5 parts of petal powder, 8 parts of calyx powder and 1 part of kiwi male flower pollen of kiwi male flower, the kiwi fruit pollen mixture was prepared and stored at 4°C. The main nutrients in the additives (filament powder, petal powder and calyx powder) in the kiwifruit pollen mixture except male flower pollen are shown in Table 2, and Lycopodium powder was used as the control group.

[0025]

Embodiment 3

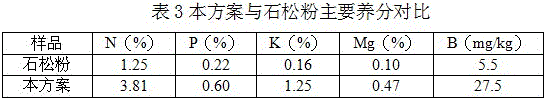

[0027] Dry the filaments, petals and calyxes of kiwifruit male flowers at 60°C for 15 hours respectively; pass the dried filaments, petals and calyxes through a 200-mesh sieve; collect the sieved powder to obtain filament powder and petal powder respectively and calyx powder: 7 parts of silk powder, 5 parts of petal powder, 9 parts of calyx powder and 1.5 parts of kiwi male flower pollen were selected and mixed to prepare a kiwi pollen mixture, which was stored at 2°C. The main nutrients in the additives (filament powder, petal powder and calyx powder) in the kiwi pollen mixture except male flower pollen are shown in Table 3, and Lycopodium powder was used as the control group.

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com