A pulse generator, generator set and energy harvesting device

A generator set and generator technology, applied in the direction of friction generators, etc., can solve the problems that cannot meet the needs of vibration mechanical collection, the structure of electromagnetic induction generators is complex, and the cost of materials has special requirements, etc., to achieve enhanced friction electrification effect, The effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

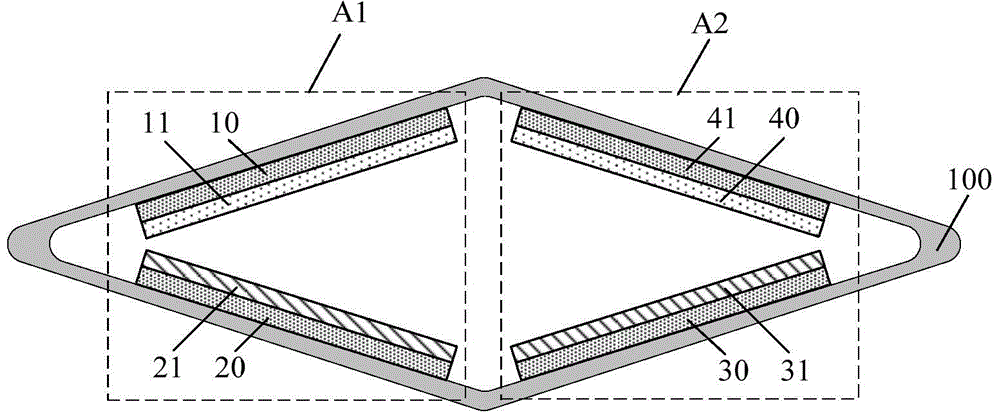

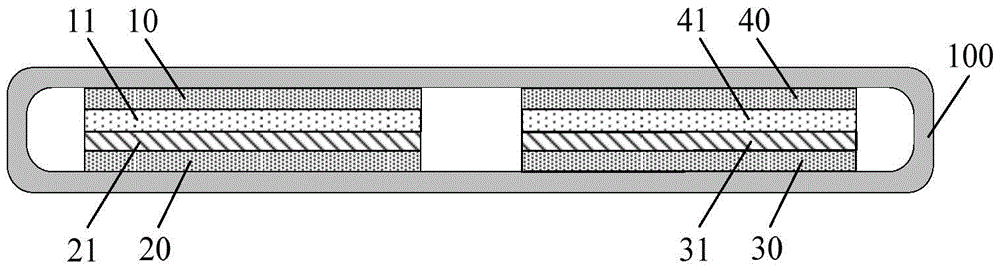

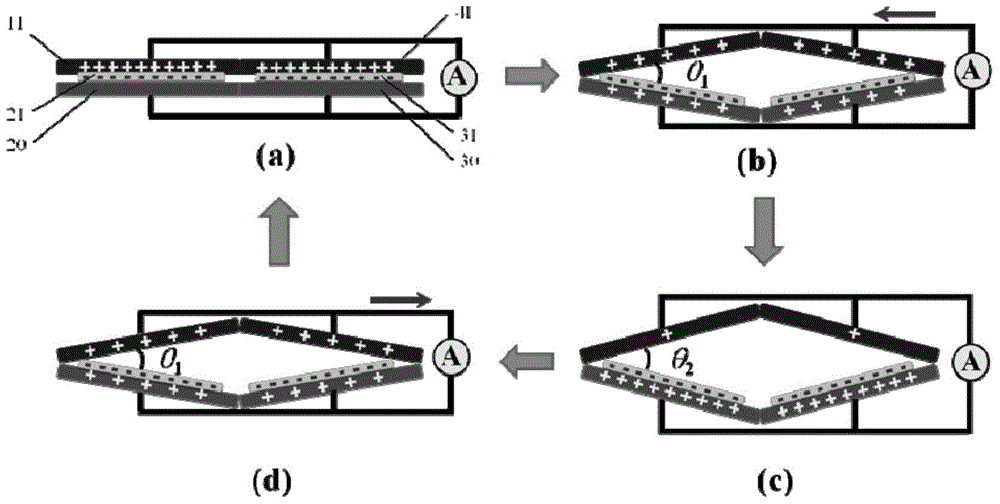

[0052] figure 1 It is a schematic cross-sectional view of a typical structure of the pulse generator of the present invention. The pulse generator includes a cylindrical base 100, the inner side wall of the base 100 is surrounded by four inner surfaces, and the included angle between two adjacent inner surfaces can be Change under the action of external force; the first electrode layer 10, the second electrode layer 20, the third electrode layer 30 and the fourth electrode layer 40 are respectively arranged on the four inner surfaces in sequence, and the upper surface of the first electrode layer 10 is contacted and arranged with The first friction layer 11, the upper surface of the second electrode layer 20 is provided with the second friction layer 21, the upper surface of the third electrode layer 30 is provided with the third friction layer 31, and the upper surface of the fourth electrode layer 40 is provided with contact. There is a fourth friction layer 41; among them, ...

Embodiment 2

[0069] In Embodiment 1, the basic structure of the pulse generator is that two friction power generation units are attached to the inner surface of the cylindrical base, and the friction layer of the two friction power generation units is driven to contact and separate by changing the angle of the inner surface of the base, and the mechanical energy is converted into for electrical energy. For the space enclosed by the inner side wall of the cylindrical base body is a straight prism, the bottom surface of the right prism is a pulse generator with a rhombus shape, the pulse generators in the first embodiment can be integrated into a pulse generator set, in the pulse generator Adjacent pulse generators in the unit can share a side wall of the matrix in the generator. Under the action of external force, the matrix of all the friction generators in the generator set deforms simultaneously, and an electrical signal is output to the external circuit. By connecting all pulse generato...

Embodiment 3

[0082] In this embodiment, the output electrical signals of the pulse generators in the second embodiment are measured, wherein the output ends of all the pulse generators are connected in parallel.

[0083] Under the action of periodic external force, in this embodiment two Image 6 The cellular pulse generator set has been measured for open circuit voltage and short circuit current, the results are as follows Figure 9-11 and Figure 12-14 as shown, Figure 9-11 is the open circuit voltage measurement result of the cellular pulse generator set under the action of periodic external force, Figure 12-14 It is the short-circuit current measurement result of the cellular pulse generator set under the action of periodic external force. It can be seen from the experimental results that the open-circuit voltage of the pulse generator set is almost unchanged with the increase of the number of pulse generators, while the maximum value of the short-circuit current increases signifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com