Hot-oil paraffin removal truck

A wax removal vehicle and hot oil technology, which is applied in the direction of cleaning equipment, isolation devices, wellbore/well components, etc., can solve the problems of insufficient heat, high cost, high fuel consumption, etc., and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

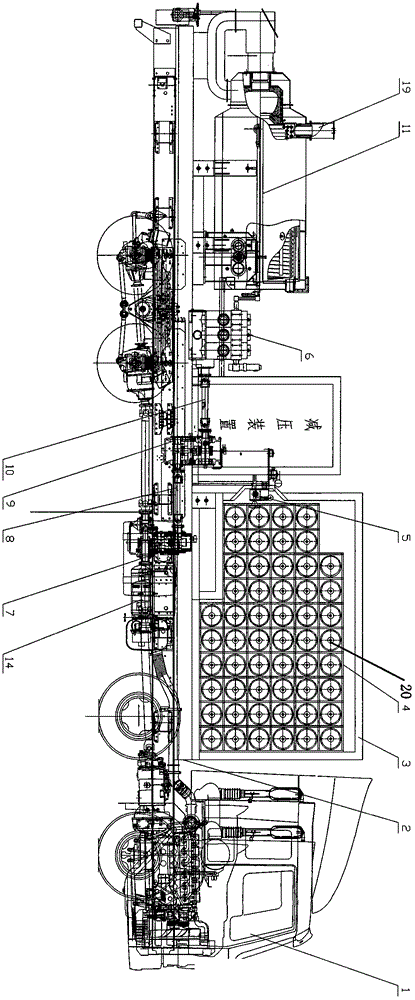

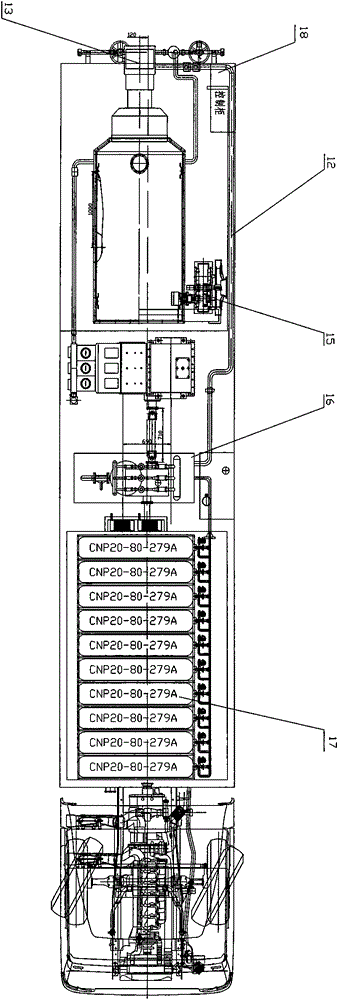

[0028] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] see figure 1 , 2 , a hot oil wax removal car, including a chassis car 1, the engine gearbox of the chassis car 1 is connected with the full power take-off box 7 through the transmission shaft, and the output of the full power take-off box 7 is connected to the reduction box 9 through the transmission shaft A8 connected, and connected with the three-cylinder plunger pump 6 through the transmission shaft B10, the outlet of the three-cylinder plunger pump 6 is connected with the water inlet of the gas boiler 11, and the burner 13 is provided at the furnace mouth of the gas boiler 11, and the burner 13 is connected with the gas output port of the gas cylinder container 20 after the three-stage decompression, the gas cylinder container 20 is set in the compartment 3 at the front end of the platform 2, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com