An automatic doffing transfer equipment for filament production

An automatic and doffing technology, which is applied in the direction of textiles and papermaking, can solve the problems of high physical fitness requirements of workers, labor shortage in the filament industry, and rising labor costs, so as to improve product quality, reduce labor intensity, and avoid pollution. and the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and embodiments.

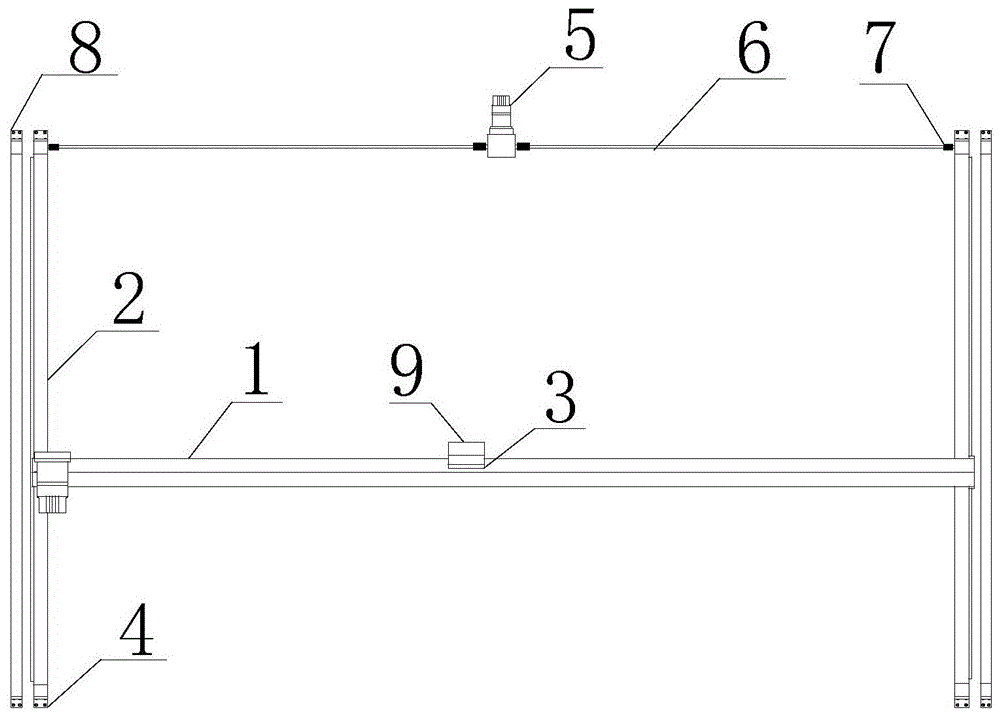

[0023] like figure 1 As shown, a kind of automatic doffing transfer equipment for filament production according to the present invention, it includes a transverse sliding table 1, a longitudinal sliding table 2 and a front and rear sliding table 3, in the transverse sliding table 1, the longitudinal sliding table 2 There are closed dust-free electric sliding table cylinders 4 on the front and rear sliding tables 3, there are two longitudinal sliding tables 2, and the transverse sliding table 1 is arranged between the longitudinal sliding tables 2. The sliding table 3 is arranged on the horizontal sliding table 1, and a servo motor 5, a connecting rod 6 and a coupling 7 are arranged between the longitudinal sliding tables 2, and they are matched and connected on the horizontal sliding table 1. A servo motor 5 is provided; a longitudinal auxiliary cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com