Methods and systems for vehicle driveline torque estimation

一种传动系、发动机扭矩的技术,应用在车辆部件、混合动力车辆、车辆子单元功能等方向,能够解决凸轮定位误差、退化、制造容差、系统误差等问题,达到改进发动机扭矩控制、改进发动机启动、改进混合式传动系操作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

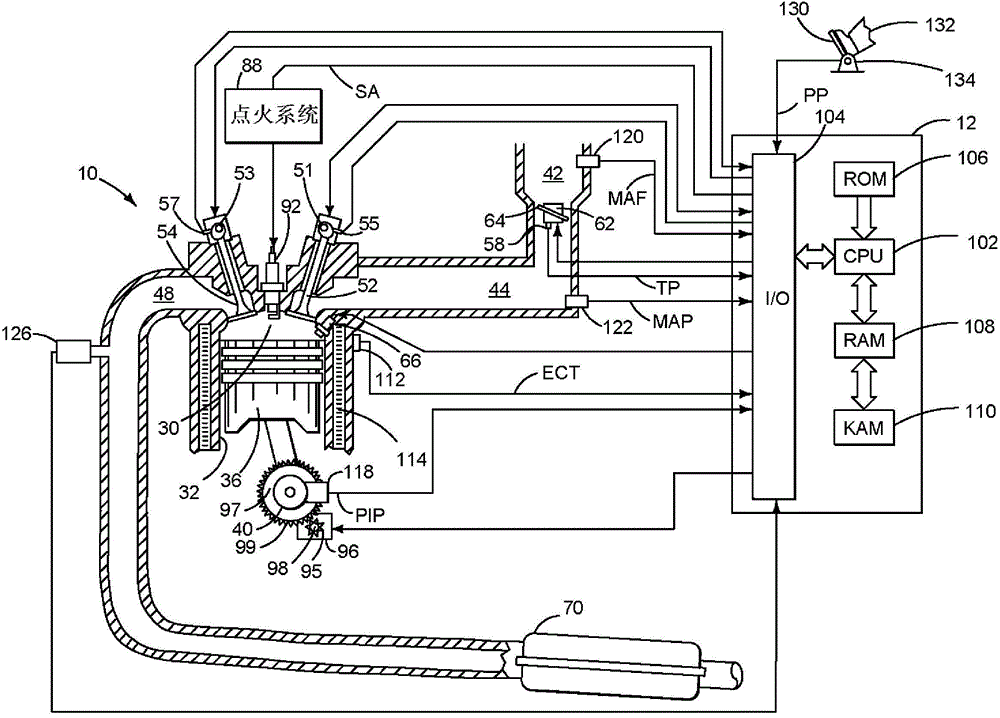

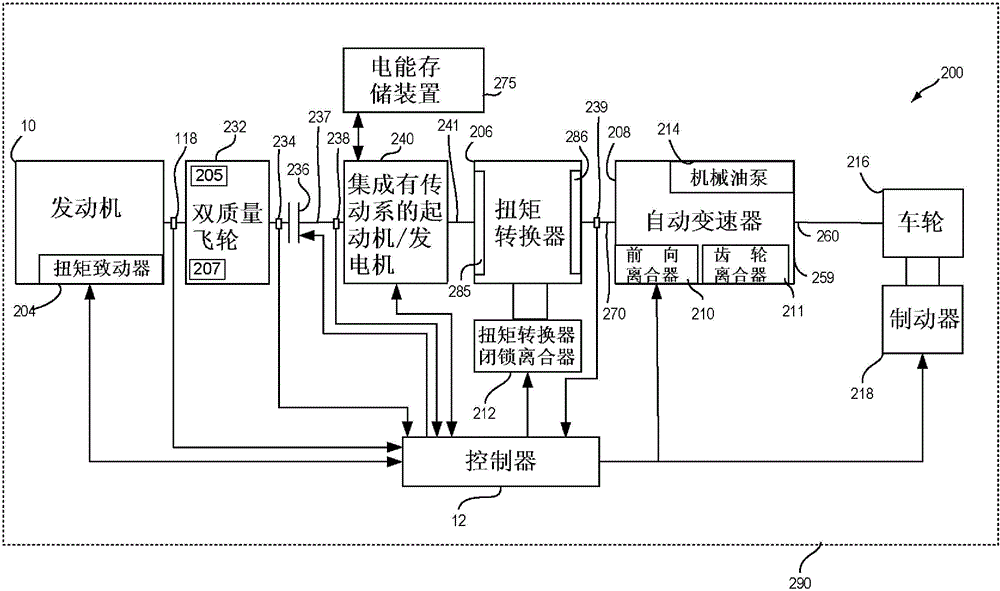

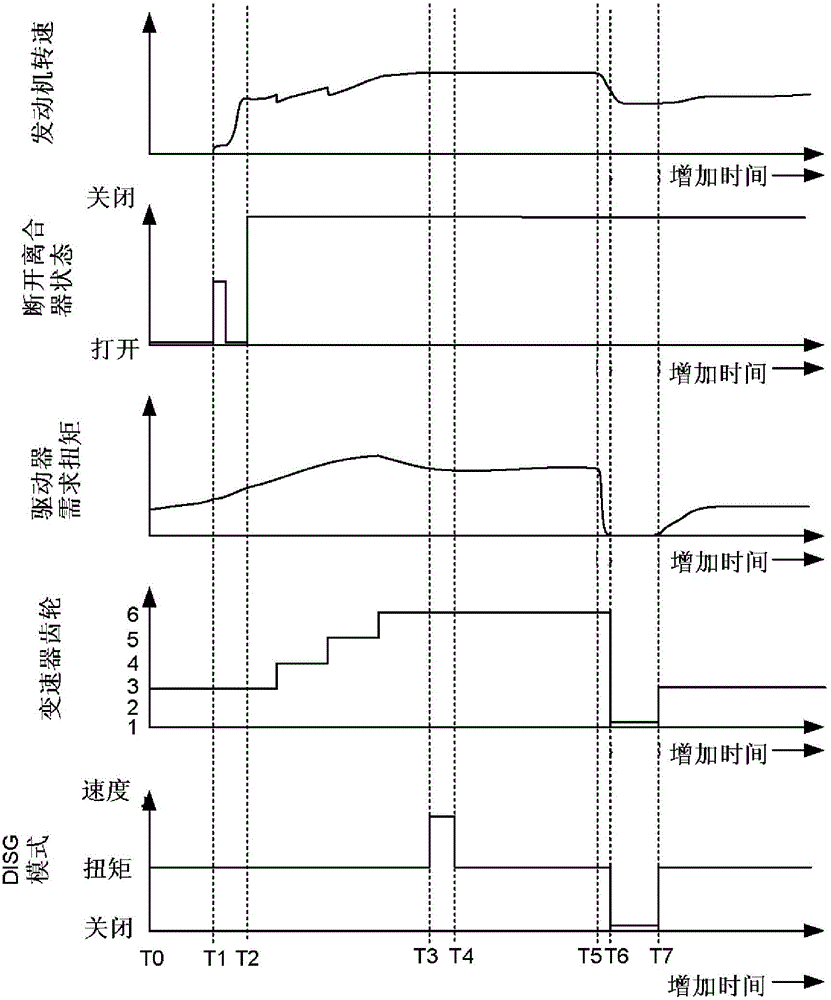

[0027] The present invention relates to controlling driveline operation of a hybrid vehicle. A hybrid vehicle can consist of an engine and a starter / generator (DISG) or electric machine (e.g., motor / generator) integrated with the driveline, such as Figure 1-2 shown. The engine may operate with or without DISG via the driveline disconnect clutch during vehicle operation. The DISG is integrated into the driveline, on the same shaft as the engine crankshaft, and rotates every time the transmission torque converter impeller turns. Additionally, DISG may not be selectively engaged or disengaged from the driveline. Rather, the DISG is an integral part of the drive train. Additionally, DISG can operate with or without operating the engine. The drive train can be as image 3 According to the sequence shown in the Figure 4 method of operation. At last, Figure 5 An example offset position between two position recognition devices is shown.

[0028] see figure 1 , including m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com