Device for printing containers, in particular by means of a rotary machine

A rotary machine and container technology, applied in the direction of rotary printing machine, printing, printing machine, etc., can solve the problem of uncontrolled discharge of printing pigments, and achieve the effect of avoiding mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

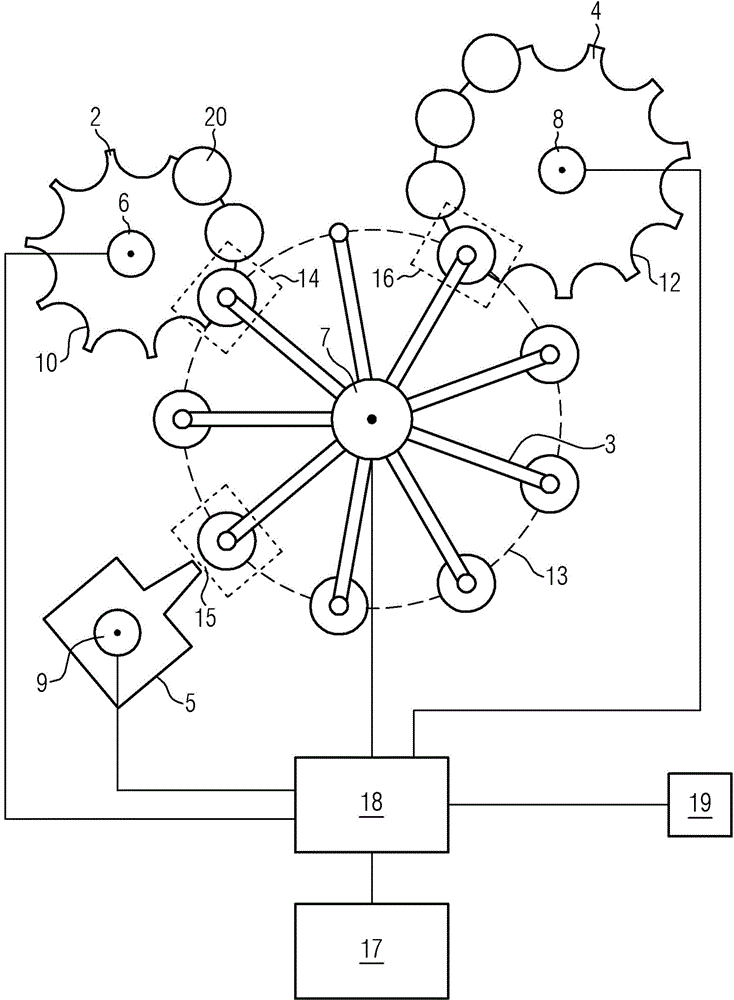

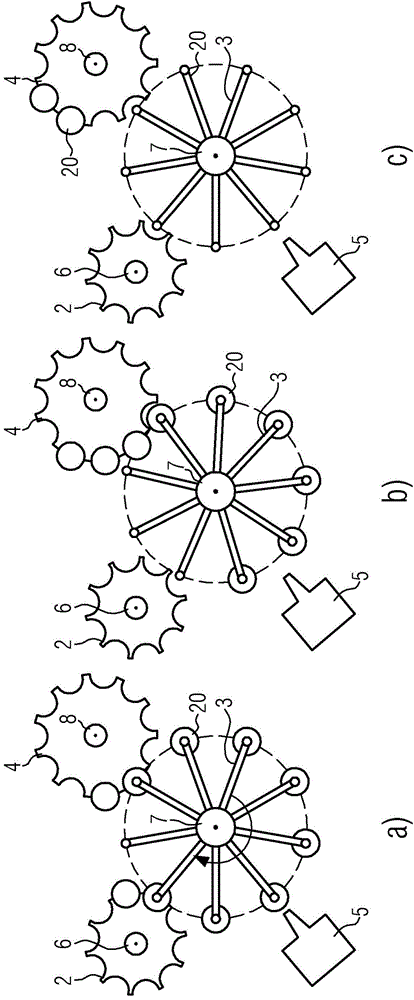

[0039] figure 1 A first embodiment of a device 1 for printing containers is shown. In this exemplary embodiment, in particular, the printing on the container is carried out by means of a rotary machine. Shown is a container input device 2 (in this case an input starwheel), a container transport device 3 (in this case a rotary member), a container output device 4 (in this case an output starwheel) and A printing device 5 (in this case a printer). It is understood that straight printed lines are also conceivable.

[0040] The printer includes in particular a printing head, but may also include a printing unit. The input starwheel is operated by the first electric motor 6 . The rotor is driven by the second electric motor 7 and the output starwheel is driven by the third electric motor 8 . The electric motors 6 , 7 , 8 correspond here to the drives. The printer includes drive means 9 . With such a drive, it is possible, for example, to move the printer along the printed ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com