A plate pressing device for laser tailor welding

A pressing device, laser tailor welding technology, applied in the direction of laser welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of inconvenient disassembly, replacement and maintenance, uneven pressing force, complex structure of the device, etc., to achieve easy disassembly and replacement Good maintenance and compaction effects, and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

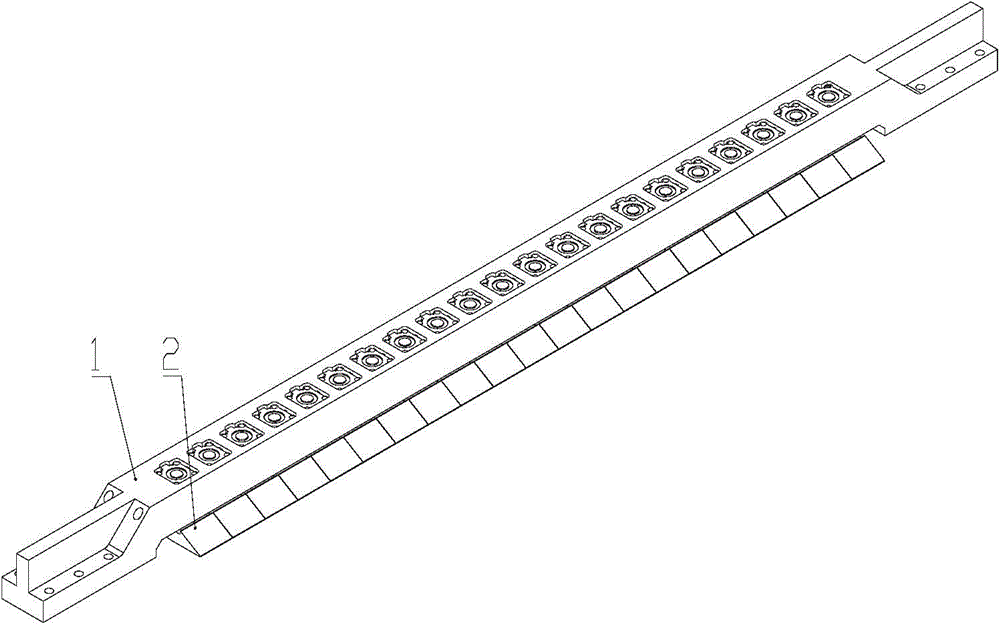

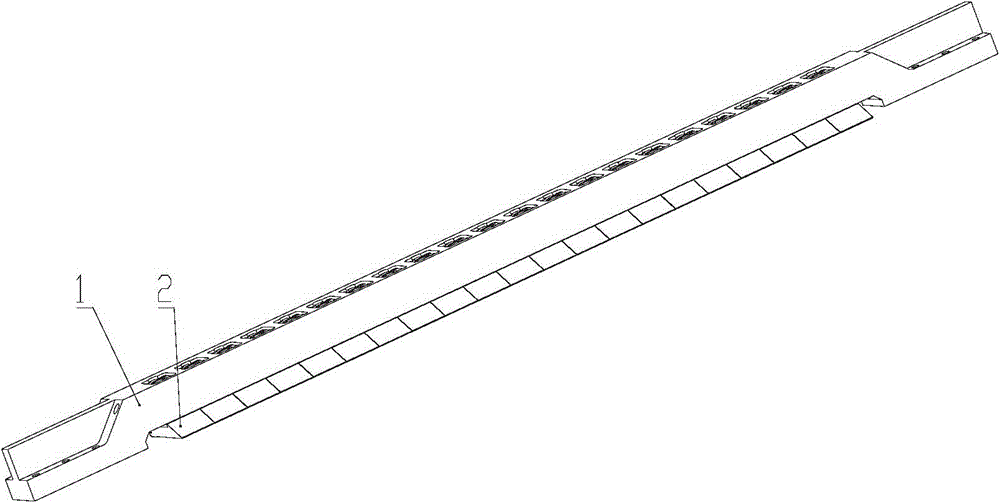

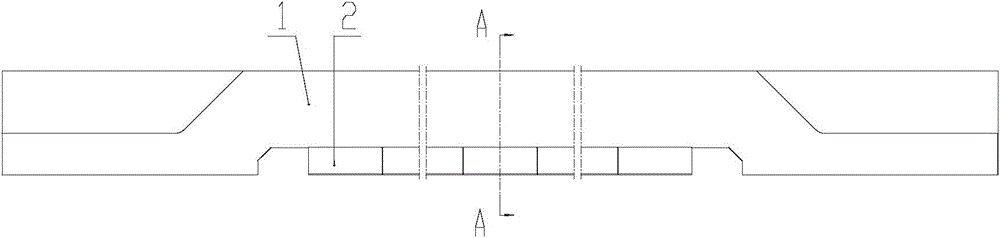

[0025] Such as Figure 1-4 As shown, a plate pressing device for laser tailor welding of the present invention includes a pressing beam 1 and a pressing assembly 2, wherein the pressing beam 1 is provided with a plurality of evenly spaced stepped through holes along the length direction, and each step The axes of the through holes are on the same straight line, the axes of the through holes of each step are perpendicular to the compression beam 1 , and a set of compression components 2 are arranged in each of the through holes of the steps.

[0026] Such as Figure 5 As shown, the compression assembly 2 includes a cylinder 201, a guide sleeve 202, a pressure plate 203, a joint bearing 204 and a guide device 205, wherein the cylinder 201 and the guide sleeve 202 are sequentially accommodated on the steps on the compression beam 1 from top to bottom. The thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com