A beam riveting fixture

A technology for riveting jigs and beams, which is applied in the field of riveting jigs for heavy-duty truck beams, can solve the problems of inability to guarantee assembly size, high work intensity of operators, and low degree of automation, and achieves the effects of high degree of automation, convenient operation and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

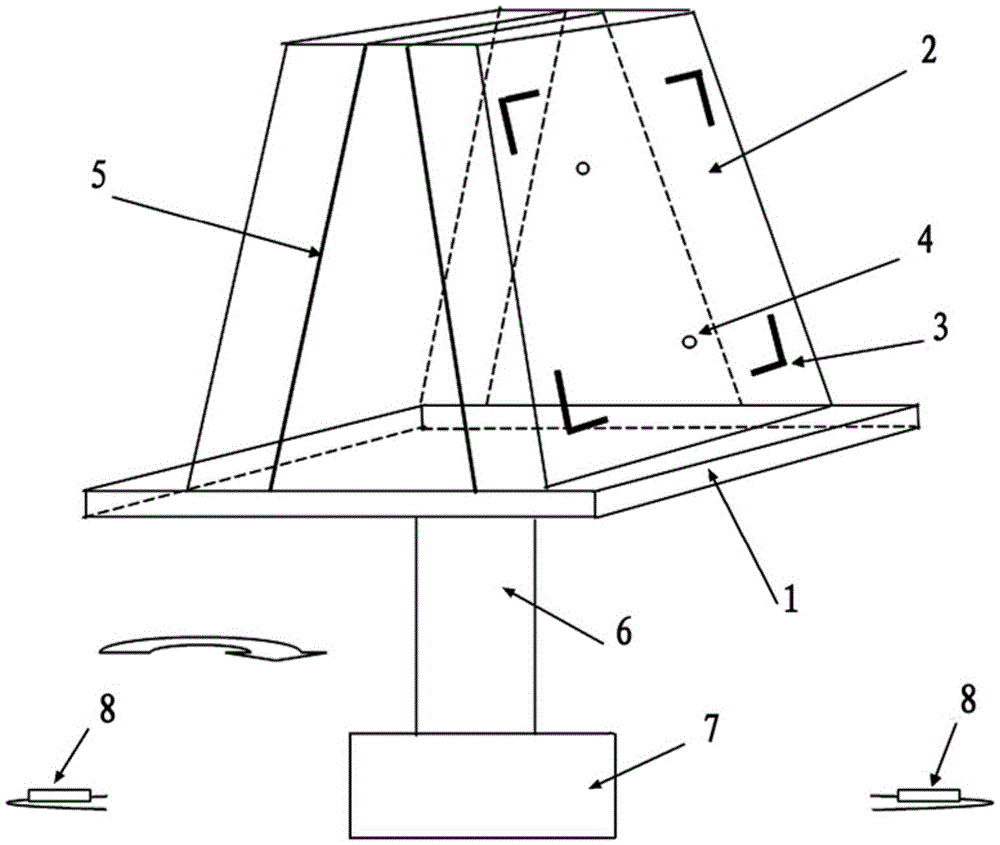

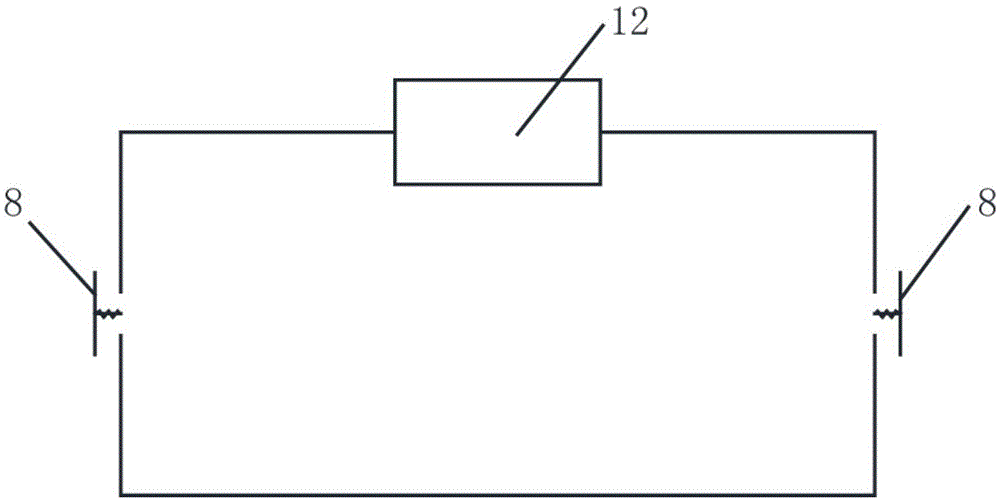

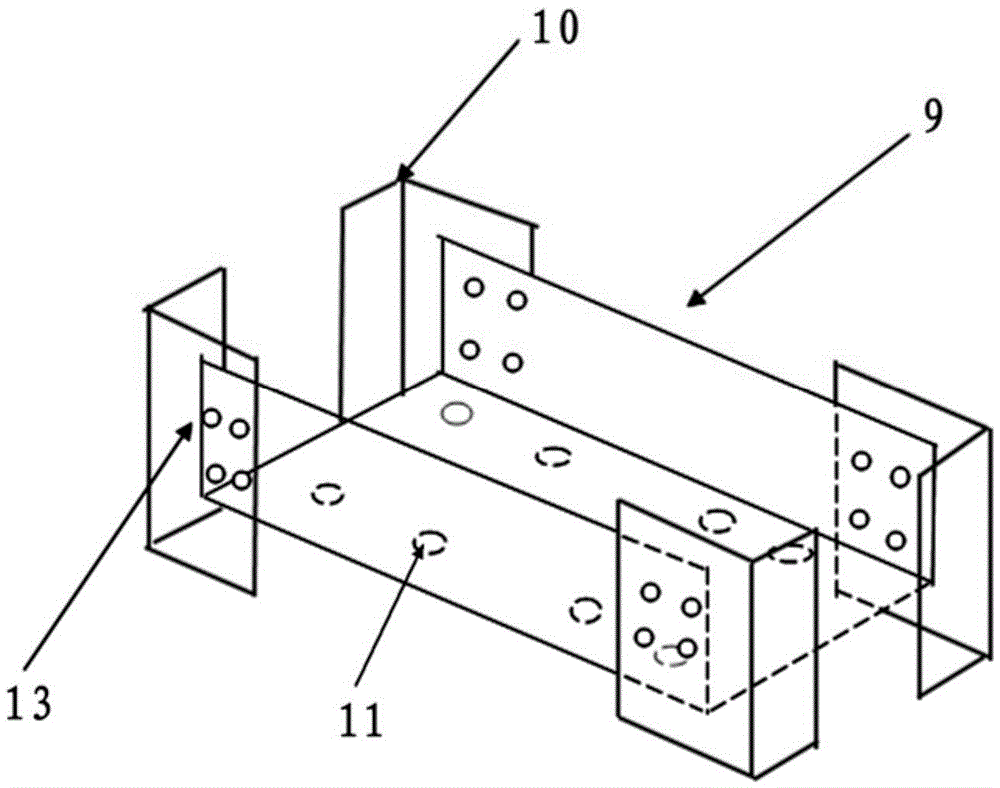

[0023] Such as figure 1 and image 3 As shown, a beam riveting jig provided by an embodiment of the present invention includes a rotatable platform 1 on which two riveting tools 2 are arranged, and the riveting tooling 2 includes a positioning notch 3 and a positioning The pin 4, the positioning notch 3 is arranged correspondingly to the beam connecting plate 10, the positioning pin 4 is arranged correspondingly to the positioning hole 11 on the beam 9, and the two riveting tools 2 are arranged symmetrically.

[0024] Usually, because the crossbeam connection plate 10 is "L" shape, therefore, the positioning gap 3 is also made into "L" shape, and the depth of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com