Large-view-field depth measuring system and method based on omni-directional structured light

A technology of depth measurement and structured light, applied in the field of measurement, can solve the problems of small field of view, inability to perceive the scene, and limit the application and development of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

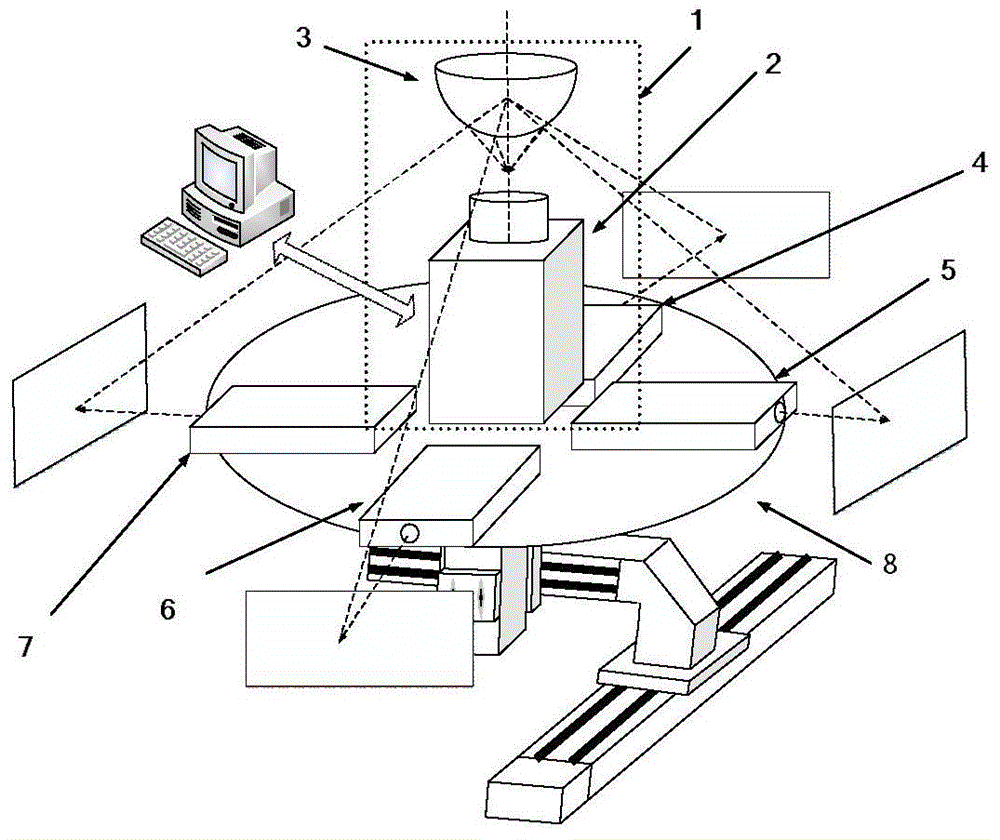

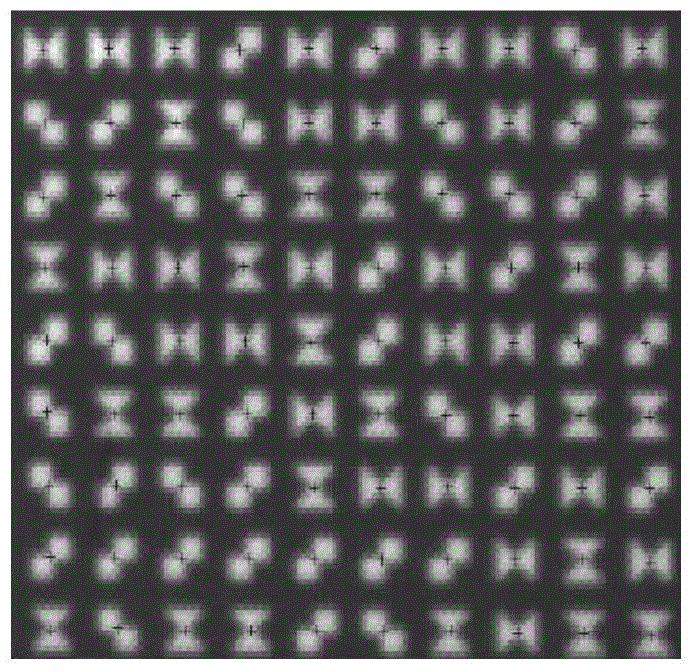

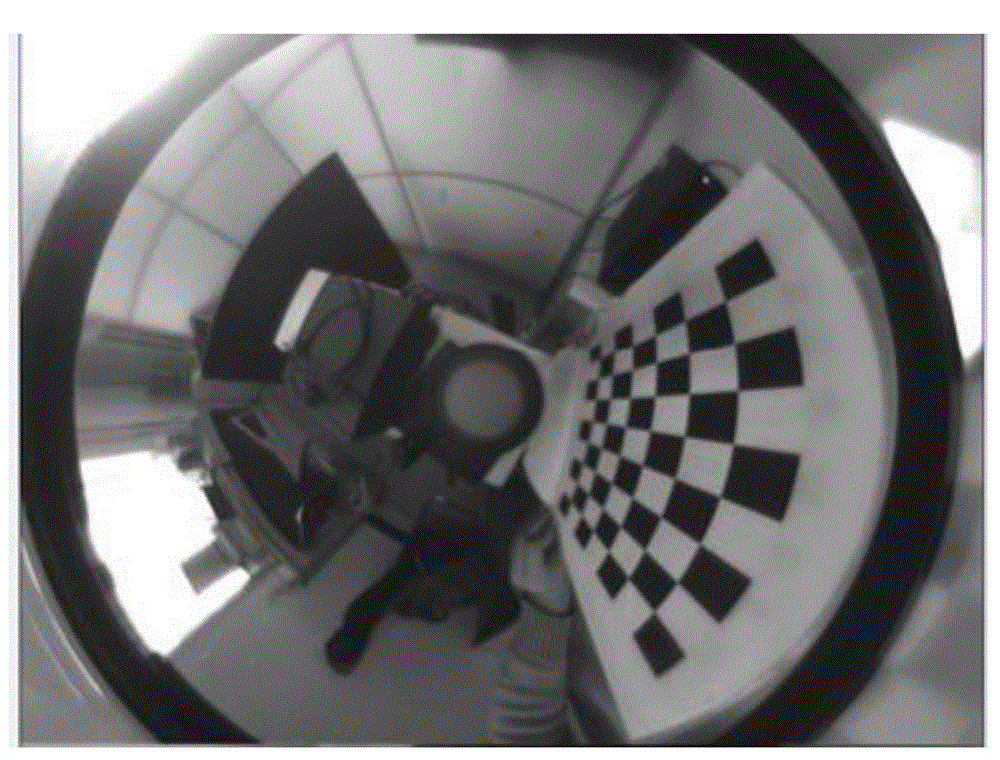

[0112] The scene depth measurement system based on omnidirectional structured light of this embodiment: the camera adopted is a Sony xcd-x710 industrial camera, and the hyperboloid reflector adopted is a hyperboloid reflector with a height of 28.85mm and a diameter of 45mm, and its focus distance from the hyperboloid The distance between the lowest point of the mirror is 4.67mm; the micro-projector used is a micro-projector with a standard resolution of 854×600, a maximum resolution of 1920×1080, a brightness of 320 lumens, a minimum projection size of 30 inches, and a maximum projection size of 180 inches. Due to the small size of the micro projector, the scene depth measurement system based on omnidirectional structured light in this embodiment has high scalability. The three-axis mobile platform of this embodiment controls its three-axis displacement through a stepping motor, and can perform precise displacement in the horizontal and vertical directions, and can realize micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com