Pilot control valve

A pilot control valve and spool technology, applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of difficult pressure adjustment, slow adjustment speed, and inability to adjust the pressure of the thread of the adjustment rod to achieve full pressure Continuously adjustable, rapid pressure adjustment, small space occupation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

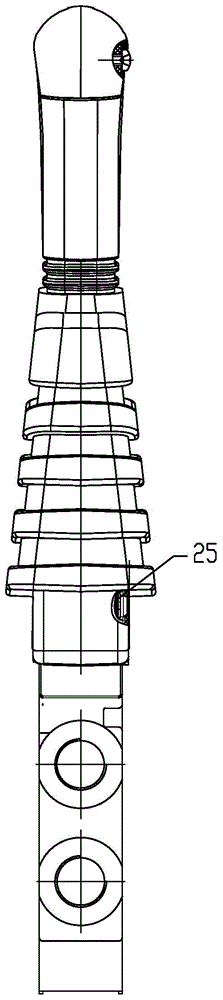

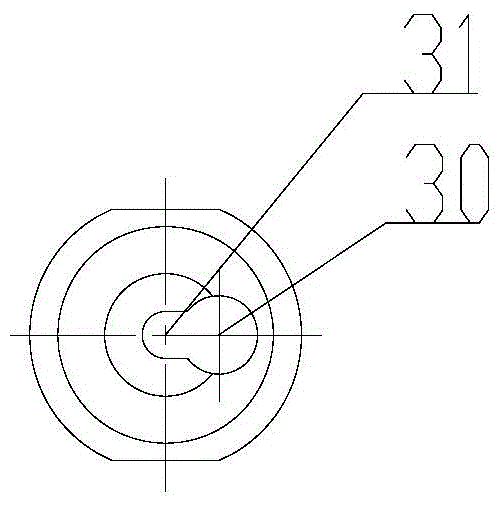

[0022] Such as figure 1 and figure 2 As shown, a pilot control valve includes a valve body 2, a valve core 3, and a handle rod 21, such as Figure 5 As shown, the valve body 2 has two stepped main valve holes 41, an oil inlet P11 and an oil outlet T9, both the oil inlet P11 and the oil outlet T9 communicate with the two main valve holes 41, and the two The lower end of the main valve hole communicates with the first working oil port 51 and the second working oil port 52 respectively.

[0023] A spool 3, a control spring 6, a spring seat 7, a push rod 13, and a push rod sleeve 12 are installed in each main valve hole 41. The head of the spool 3 is inserted into the spring seat 7, and the control spring 6 is installed on the spring seat 7. Between the valve core 3 , the upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com